Tuesday, December 11th 2012

Cougar Shows Technical Production Designs of Their VORTEX Fans

COUGAR, leading German PC case and power supply brand, has released technical details on their VORTEX fans. COUGAR launched this product in November of 2011 and today it has become COUGAR's best selling product with over 200,000 units sold in the USA. After a year of having received outstanding feedback from system builders and enthusiastic DIY users, the VORTEX fans have a proven track record.

The VORTEX product has been designed and tested under a series of strict criteria including air flow, air pressure, noise, performance and lifespan. The engineering has proven the design to be the optimal combination of cooling efficiency, silent operation and high lifespan, making it one of the best cooling fans on the market.Why is the VORTEX fan so different from all other fans? COUGAR has made new technical designs available to explain the differences.

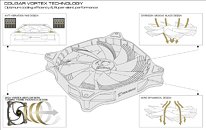

HIGH-VORTEX-AIRFLOW WITH TURBINE BLADE & FRAME DESIGN - This is a patented design that allows for optimum airflow, air pressure, cooling efficiency and extremely quiet performance.

The PWM-FUNCTION

PWM stands for Pulse Width Modulation. The 4-Pin connector allows the mainboard to control the fan speed from 800-1500 RPM. Fan speed is controlled by the PWM-signal, which delivers a value between 0-100%, the operating voltage remains a constant 12V.

ANTI-VIBRATION PAD & AERO-DYNAMIC DESIGN - This reduces the vibrations efficiently and assures silent operation. The air-inlet with optimal aero-dynamic design reduces noisy air turbulence.

HYDRO-DYNAMIC-BEARING TECHNOLOGY

COUGAR's HDB or Hydro Dynamic Bearing design is an oil seal designed giving a higher reliability compared to conventional fan motor designs. The HDB design allows these features:

1. Higher revolution precision for low vibration noise.

2. Fluid seal design, providing extremely long lifespan.

3. Surface tension effect allows for smoother running with decreased friction, making it extremely quiet.

The fluid seal design is achieved through the use of oil surface tension and hydrodynamic pumping forces provided by grooves. The bend area has centralized oil and prevents oil leakage out of the motor (oil leakage is the main design flaw of sleeve and bearing products and produces a shortened life time). Friction between shaft and HDB will be decreased due to the herringbone structure reaction (friction between the metal is a disadvantage of the ball bearing design producing noise and waste heat problems). In these ways HDB technology conquers the sleeve and ball bearing disadvantages to become a more reliable and quiet technology. Similar design concepts are successfully used in hard drives, and COUGAR has reliably applied them in the VORTEX products.

The VORTEX product has been designed and tested under a series of strict criteria including air flow, air pressure, noise, performance and lifespan. The engineering has proven the design to be the optimal combination of cooling efficiency, silent operation and high lifespan, making it one of the best cooling fans on the market.Why is the VORTEX fan so different from all other fans? COUGAR has made new technical designs available to explain the differences.

HIGH-VORTEX-AIRFLOW WITH TURBINE BLADE & FRAME DESIGN - This is a patented design that allows for optimum airflow, air pressure, cooling efficiency and extremely quiet performance.

The PWM-FUNCTION

PWM stands for Pulse Width Modulation. The 4-Pin connector allows the mainboard to control the fan speed from 800-1500 RPM. Fan speed is controlled by the PWM-signal, which delivers a value between 0-100%, the operating voltage remains a constant 12V.

ANTI-VIBRATION PAD & AERO-DYNAMIC DESIGN - This reduces the vibrations efficiently and assures silent operation. The air-inlet with optimal aero-dynamic design reduces noisy air turbulence.

HYDRO-DYNAMIC-BEARING TECHNOLOGY

COUGAR's HDB or Hydro Dynamic Bearing design is an oil seal designed giving a higher reliability compared to conventional fan motor designs. The HDB design allows these features:

1. Higher revolution precision for low vibration noise.

2. Fluid seal design, providing extremely long lifespan.

3. Surface tension effect allows for smoother running with decreased friction, making it extremely quiet.

The fluid seal design is achieved through the use of oil surface tension and hydrodynamic pumping forces provided by grooves. The bend area has centralized oil and prevents oil leakage out of the motor (oil leakage is the main design flaw of sleeve and bearing products and produces a shortened life time). Friction between shaft and HDB will be decreased due to the herringbone structure reaction (friction between the metal is a disadvantage of the ball bearing design producing noise and waste heat problems). In these ways HDB technology conquers the sleeve and ball bearing disadvantages to become a more reliable and quiet technology. Similar design concepts are successfully used in hard drives, and COUGAR has reliably applied them in the VORTEX products.

16 Comments on Cougar Shows Technical Production Designs of Their VORTEX Fans

Edit:

Actually I stand corrected, I bought the version in this article on Newegg for 9.99 each during Black Friday.

Right now they are thirteen dollars though.

I was disappointed with these. The static pressure is not high enough to make them very good rad fans to the point that I question the 2.2 mm H2o rating

I just bought one of these and i have to say im very impressed.

I dont know who's saying their noisy but these things a super quiet.

I two in a push and pull setup the PWM isnt noisy.

There getting confused with the fact that any time you crank up the rpm of a fan more noise will be produced.

Plus they look great

EDIT: What he said :P..

just slap a magnet on the back and it takes care of the shake COMPLETELY..(must be fairly strong magnet)

$12.99-$14.99

I'd like to try some out, be interesting to see some reviews including static pressure ;)

Keep in mind, this graph was paid for by corsair. Corsair AF & SP Series Computer Case Cooling Fans ...