Thermalright XWB-01 Water block Flow Rate Testing

Introduction

Welcome to my pressure drop testing of the Thermalright XWB-01 Waterblock for processor. This page will focus on the pressure drop and flow characteristics only for this water block only. I will follow up at a later date to assess thermal performance when I've completed construction of my die simulator testing setup.

First off I want to give special thanks Gary from Sidewinder Computers for providing me with the water block sample to review. I've ordered from Sidewinder many times and it's always been a pleasure repeatedly finding my next favorite part there as they typically are priced lower than many others. They are also committed to helping the water cooling community further develop an understanding of water cooling and I have seen them provide testing parts to several water cooling forum members. I highly recommend giving Sidewinder Computers a try on your next shopping adventure:

Block Characteristics

And look here, it comes with a back-plate!, barbs, hose-clamps, and the necessary screws. Unfortunately the back-plate is not a stud type, it is a front loading type that will require motherboard removal during maintenance removal. You could however modify the mounting screws by replacing them with studs, plastic nuts, and waters and still utilize this back-plate in a normal stud system that would allow future access without removal. It's also nice to see enough thermal grease for the next 10 years worth of applications, that's a lot of "thin line" applications.

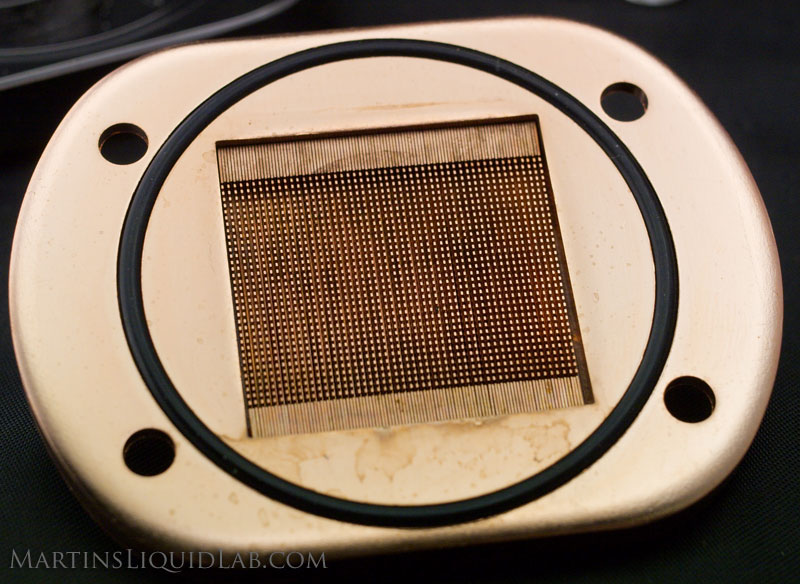

The mid-plate and mid-plate washer forces water appropriately down into the pin matrix and out radial in direction to the exits slots that return water to the outlet port. I anticipate these design features add up to a very well performing block.

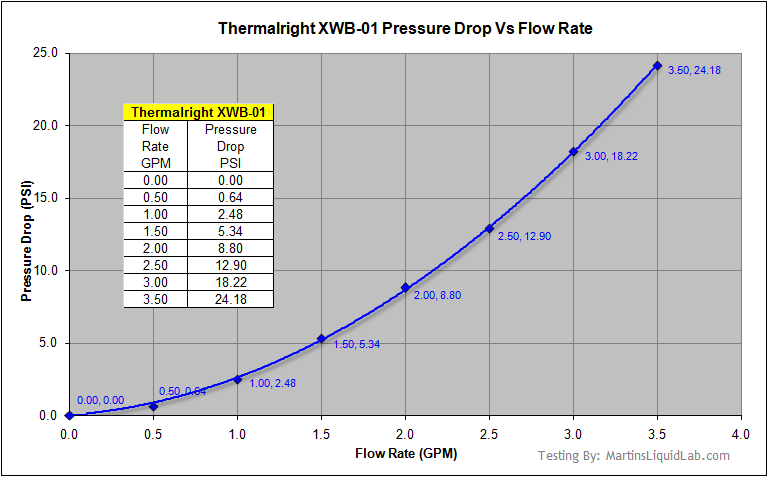

Hydraulics and Pressure Drop Testing

The most scientific way to determine a blocks hydraulic resistance is to test pressure drop. Pressure drop is a measurement of pressure loss across a block that varies with flow rate. This is basically a measurement of energy loss, and directly influences how much flow rate you will have.

- Dwyer Digital Manometer 475 Mark III - Accuracy .5% of Full Scale. Range 0-200" W.C., Resolution .1" W.C.

- King Instruments 7520 Series 0-5GPM, 250mm scale - Accuracy 2% of Full Scale. Range 0-5GPM, Resolution .1GPM (can be interpolated to .02GPM)

- Water Source - Household water pressure - 50PSI at >5GPM - Because flow rate readings are instantaneous, household tap water and water pressure are a good and powerful source for pressure drop testing.

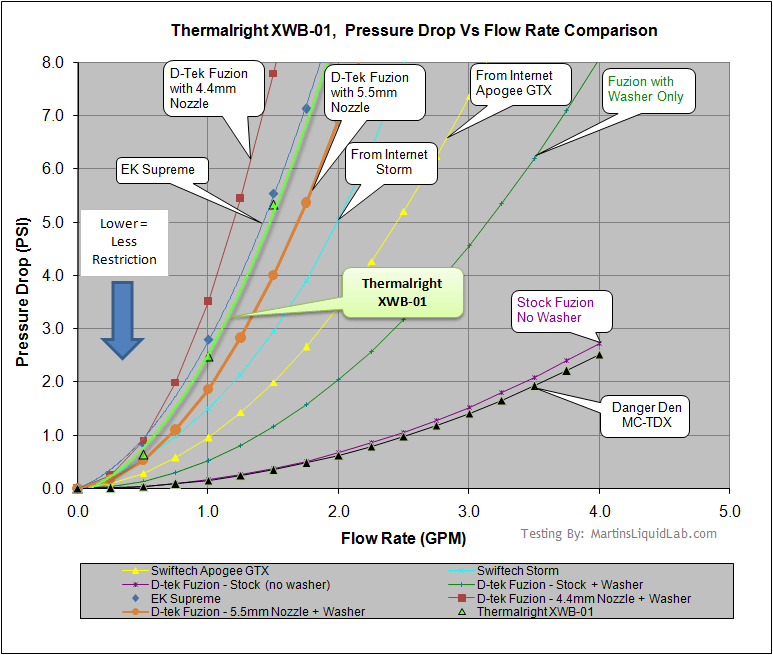

And to get a better sense of restriction comparison, here it is with several other curves. It follow very closely to that of the EK Supreme and somewhere between the 4.4 and 5.5mm nozzle with the fuzion.

I would simply suggest that you plan out your system more carefully with high restriction items. High restriction blocks go very well in single block loops because any impacts to flow rate have no effect on other blocks in the same system, only the radiator which are generally very resilient to flow rate impacts. I would recommend due to this higher restriction that you simply check flow rate on a designed system and ensure 1GPM is maintained. This is a good rule of thumb flow rate point where gains beyond mean less than a couple of degrees.

Thermal Testing Link

Hardware Canuck's Thermal Testing Link

Their results indicate the block does perform well and similar to an Apogee or stock Fuzion on a quad core. Unfortunately there was not a comparison with a Fuzion in full fighting nozzle gear or an EK supreme that would more closely match the restriction the Thermalright block produces. Typically I've seen users report approximately 2-3C gains with a nozzle/washer on the fuzion, so it would be a tough race for the top.

Regardless, this is very good thermal performance and considering Thermalright's track record for dominating the heat sink market, I'm not surprised to see it perform so well even if it is one of thermalrights first water blocks. Can't wait to see what they have up their sleeves next.

Price Considerations

Prices as of 4-7-2008

Considering the inclusion of the back-plate and all metal construction, that makes the Thermalright XWB-01 a noteworthy price competitor as well.

Where to Buy

Sidewinder Computers Thermalright XWB-01