XSPC Dual Bay Reservoir Pump Review

Introduction

Welcome to my XSPC dual bay reservoir pump review. I would like to give special thanks to Paul from XSPC for yet another great product to review, the products I have tested have all been a pleasant surprise in the amount of attention XSPC gives towards top performance at great prices. They really put 100% into making products that perform well and a true tribute to their commitment in developing products that perform well!

With this review I will focus on the performance characteristics of the dual bay reservoir pump from the XSPC line.

Reservoir Pump Characteristics

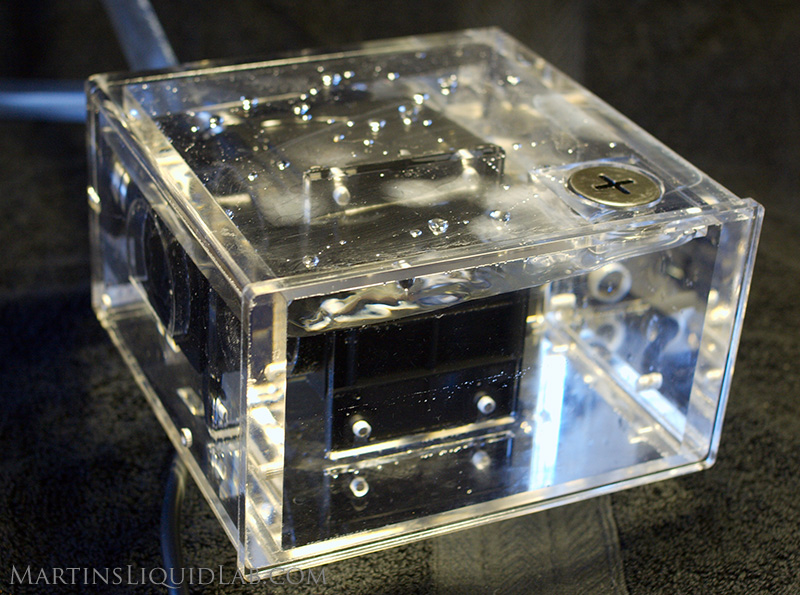

The reservoir pump I'm looking at on this page is a dual bay acrylic reservoir that contains a fairly larger submersible pump in one handy component. This dual bay reservoir is intended to mount like a CD drive so the clear front you see below is completely visible in the front of your case bezel providing a nice visual of your coolant level and pump in operation. The bay reservoir and mounting materials are all made of acrylic and include brass threaded inserts for the bay mounting screws for added mounting durability. The pump also comes with one 12V LED and two locations predrilled for accepting LEDs in the rear sidewalls for additional lighting effects if desired.

And here is a side view showing the rear facing barb location and power connection. Inlet barb is on the left then the power connection, and the outlet barb on the right. The inlet barb is nice and low in the reservoir rear wall circulating water completely around the face of the reservoir before returning to the protected pump inlet for maximum air bleeding capabilities.

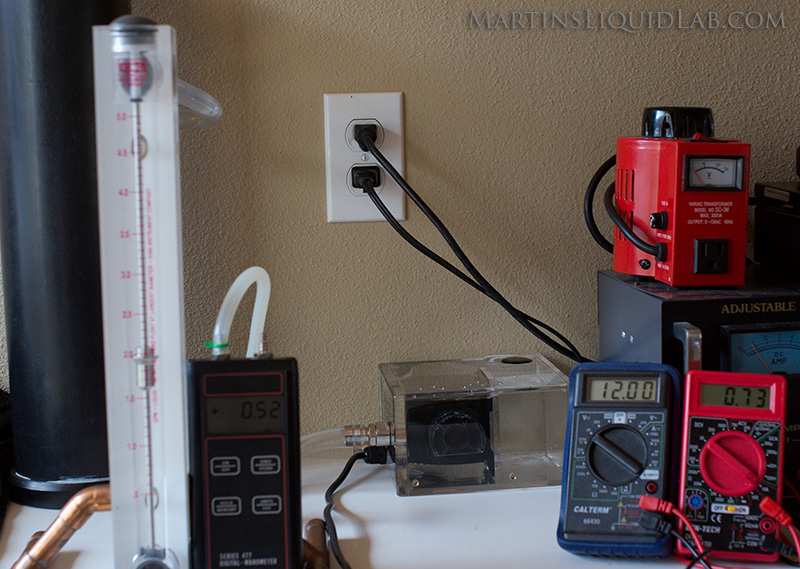

Hydraulics Pump Testing

The most scientific way to determine a pumps performance is to plot the entire pump pressure vs flow rate curve. This can be done by measuring pressure at the outlet of the pump with a digital manometer and using a gate valve immediately after this pressure measurement point. Then utilizing this gate valve, adjusting the amount of restriction will net different flow rates and coinciding pressures the pump is producing over its curve. All of this is preferably done at a very precise 12.00V or the tested voltage as needed. While testing for pressure and flow rates, data was also collected using multi-meters to capture voltage and current in amps for power consumption data.In this particular test the pump was specified to run at 12.0V and likely where most water cooling users would operate it, so all testing was conducted at 12.00V +- .03V. I found the pump would start as low as 5.1V and up to 13.0V and operate just fine. I did not exceed 13.0V for my test, although it would likely go beyond that point.

Equipment:

- Dwyer Digital Manometer 477 Mark V - Accuracy .5% of Full Scale. Range 0-20.00 PSI range, Resolution .01 PSI

- King Instruments 7520 Series 0-5GPM, 250mm scale - Accuracy 2% of Full Scale. Range 0-5GPM, Resolution .1 GPM (can be interpolated to .02GPM)

- Water Source - Household water pressure - 50PSI at >5GPM - Because flow rate readings are instantaneous, household tap water and water pressure are a good and powerful source for pressure drop testing.

- Samlex PSA-305 Variable DC Power Supply - Adjusted voltage to be at 12.00V +-.03V.

- Calterm 66430 Multi-meter - Measured Voltage (DC Volts to .01V resolution)

- Cen-Tech Digital Multi-meter - Measure Current (Amps to .01 Amps Resolution)

- Mastech MS8209 Auto Ranging Multi-meter - Used for sound level decibel measurements. (.1db resolution)

And my results are as follows:

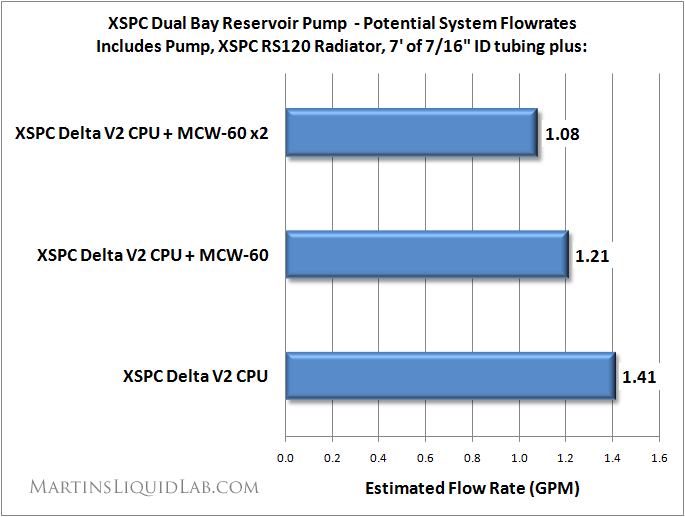

The XSPC dual bay reservoir pump does particularly well with the low restriction blocks and radiators of XSPC. A general rule of thumb for flow rates is to maintain a minimum of .9GPM, preferably 1.0GPM or better. The reason for this is that thermal performance for many blocks is very flat beyond this point, so additional flow rates produce little to no measureable performance gain in temperature. Because XSPC happens to have some very low restriction blocks and radiators, I thought it would be helpful to estimate the actual flow rates for various setups. The following are several estimated flow rates based on pumping and pressure drop curves I have tested myself, you can expect the following (keep in mind the 0.9GPM minimum rule of thumb) I included the XSPC RS120 radiator and XSPC Delta V2 CPU since I had recently tested them. I also included one and then a second Swiftech MCW-60 just to see how it would do with a potential CPU/GPU and CPU/GPU SLI combo on flow rates. These are all low restriction blocks and an estimate based on calculated curves, but a good estimate of flow rates you can expect:

Reservoir Bleeding Performance and Sound Level

I'm very impressed with the reservoir performance in its ability to remove air bubbles from the system and operate at a large range of depth levels. Most single bay reservoirs have a very small amount of good operational level drop before they start sucking air back into the outlet barb and into the system. Remember air is an insulator so air bubbles are not good in your coolant, so bleeding the system of air and maintain that is an important performance task.Here is a short video of the pump running with my decibel meter running alongside. It's difficult to be empirical with bleeding capabilities and noise, so I'm beginning to do some small video recordings to let my readers make up their own minds on the issue. I recorded this in the evening when it's the most quiet in my house (kids were off to bed), so I hope I've also captured the pump sound for you to evaluate yourselves. The pump was extremely quiet in my opinion with low very vibrations as well, so I suspect this pump would fulfill the needs of even the most particular silence enthusiast. With an average room ambient noise level of 46.7db, after switching the pump on and recording levels about 6" away, the sound level rose to about 49.7 or a 3.0 db total increase.

Conclusion

I'm very impressed with bay reservoir pump for several reasons. First while it is a smaller pump, it still has plenty of power to run multiple block systems as long as the components are chosen and matched wisely. But more importantly it can do this with very minimal power consumption and with silence. In addition the large dual bay reservoir does a great job at bleeding and can operate with a varied level of coolant so the old problems I've seen with my old bay reservoir would not be an issue here. Also I like the nice large clear front view, it looks nice but it also functions to provide you with a visual on coolant levels and the slight movement in water would indicate all is well with the pump and flow rate is good. Finally the low power consumption and heat dump is very important particularly for smaller radiator systems where it counts the most.The

XSPC Dual Bay Reservoir Pump delivers silent performance with

extremetly low heat dump and power consumption!

Where to buy

XSPC Retailers Link