D

Deleted member 185158

Guest

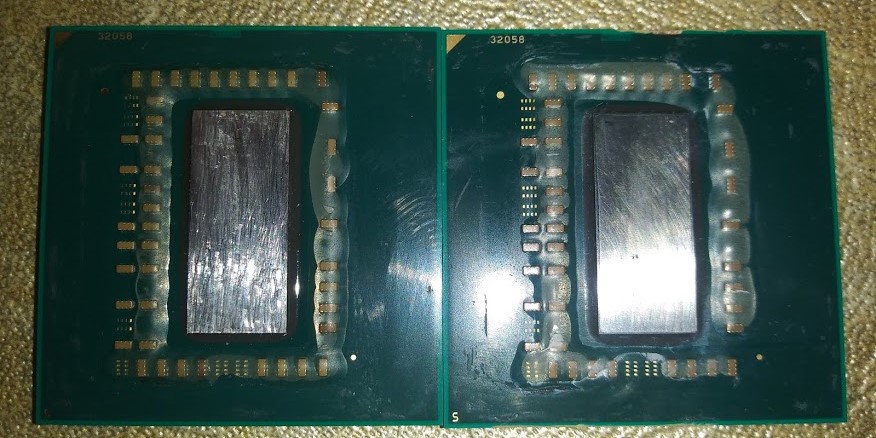

Just wanted to show the under hood of a Ryzen 2700X that's actually used daily with it's hat removed.

Method: Soldering torch

Time: Including cutting the glue around the edges, oh 15 minutes or so. Actual fire to plate, under 60 seconds.

Use Time: While de-lidded... a few months now. (still in use daily)

Use Method: Now Gaming Started with testing chip behavior.

Cooling Used: Air, Liquid and TEC cold plate to die. (not chill loop)

Recent Chips delidded: 200ge (no solder) 220ge (no solder) Ryzen 1200 and Ryzen 2700X (many more previous generations soldered AMD processors)

Using a small model vice, I heat sink the pins to a large based heatsink and clamp the PCB in the vice. To give size, Jaw opening 1.5 inch and 3 inch. It's small fits in your hand. Vice grip IHS plate. Add heat with solder torch on med to high flame. On average the solder melts in 48-52 seconds. Quiet room, can hear when the solder melts, it happens all at once. Pull lid off, quickly cool the chip with a small fan and done. Pretty simple process, been pretty successful.

So it's a long story, but I've found no real reason to delid Ryzen processors. There is no gains to be seen even running lower than ambient core temps. The chilling does help to reduce leakage and allows for a lower v-core to be obtained and remain stable. However removing the solder hasn't helped the cause for cooler temps..... Unless it's applied for fun and testing purposes. I always have the most challenging fun trying to cool processors with a cold plate and TEC. Not as easy as it sounds. But this also depends on what your looking to do! I try to maintain a frozen processor, but also test going above freezing to see if it caused any reaction. Those tests have been done some time ago, but never the less didn't have any bad experience with it at all. I can touch on cooling and such more if requested.

In the past, de-lidding helped quite a bit as cooling increased headroom (typically Phenom and FX chips) had an average of 10c drops in temps and 100mhz increased frequency. Well with these new chips, the average is a tad different.

On air cooling, re-using the IHS plate substitute the solder with TIM, made matters a tad worse, but not as bad as expected!! I run a daily clock of 4.1Ghz at 1.412v just the same as if the solder was there. Temps are a little higher for sure when loading the IBT or Prime95 and I also enjoy OCCT too. Reaching throttle point happens much faster when running 4.2ghz and 1.43750v and that is where the ill return came in with the stock cooling. Kiss high clocks and higher voltage by by. Before the de-lid on stock cooling, reached a max clock of 4500mhz and a pretty stable x4 4.4ghz. Max Cinebench stable run was at 4300mhz All threads, now only to 4100mhz. So on ambient air coolers and AIO, this is actually not going to fair well. But don't let me leave out that 4.1Ghz on this 2700X is actually it's most stable overclock. PBO won't even pass this frequency. So manual clocking it is.

Well I ramble a little. Pics or didn't happen right?

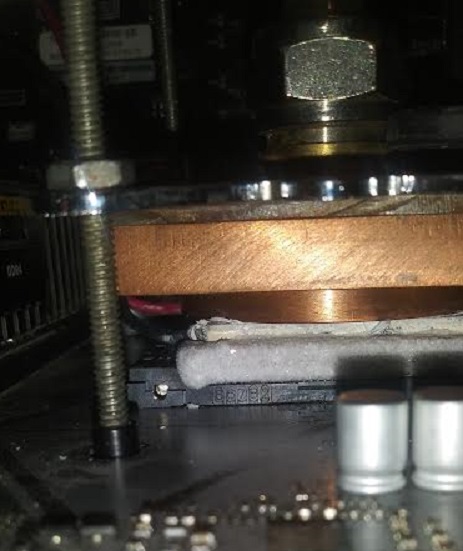

A little TEC frost there. That copper plate is directly on the core.

Method: Soldering torch

Time: Including cutting the glue around the edges, oh 15 minutes or so. Actual fire to plate, under 60 seconds.

Use Time: While de-lidded... a few months now. (still in use daily)

Use Method: Now Gaming Started with testing chip behavior.

Cooling Used: Air, Liquid and TEC cold plate to die. (not chill loop)

Recent Chips delidded: 200ge (no solder) 220ge (no solder) Ryzen 1200 and Ryzen 2700X (many more previous generations soldered AMD processors)

Using a small model vice, I heat sink the pins to a large based heatsink and clamp the PCB in the vice. To give size, Jaw opening 1.5 inch and 3 inch. It's small fits in your hand. Vice grip IHS plate. Add heat with solder torch on med to high flame. On average the solder melts in 48-52 seconds. Quiet room, can hear when the solder melts, it happens all at once. Pull lid off, quickly cool the chip with a small fan and done. Pretty simple process, been pretty successful.

So it's a long story, but I've found no real reason to delid Ryzen processors. There is no gains to be seen even running lower than ambient core temps. The chilling does help to reduce leakage and allows for a lower v-core to be obtained and remain stable. However removing the solder hasn't helped the cause for cooler temps..... Unless it's applied for fun and testing purposes. I always have the most challenging fun trying to cool processors with a cold plate and TEC. Not as easy as it sounds. But this also depends on what your looking to do! I try to maintain a frozen processor, but also test going above freezing to see if it caused any reaction. Those tests have been done some time ago, but never the less didn't have any bad experience with it at all. I can touch on cooling and such more if requested.

In the past, de-lidding helped quite a bit as cooling increased headroom (typically Phenom and FX chips) had an average of 10c drops in temps and 100mhz increased frequency. Well with these new chips, the average is a tad different.

On air cooling, re-using the IHS plate substitute the solder with TIM, made matters a tad worse, but not as bad as expected!! I run a daily clock of 4.1Ghz at 1.412v just the same as if the solder was there. Temps are a little higher for sure when loading the IBT or Prime95 and I also enjoy OCCT too. Reaching throttle point happens much faster when running 4.2ghz and 1.43750v and that is where the ill return came in with the stock cooling. Kiss high clocks and higher voltage by by. Before the de-lid on stock cooling, reached a max clock of 4500mhz and a pretty stable x4 4.4ghz. Max Cinebench stable run was at 4300mhz All threads, now only to 4100mhz. So on ambient air coolers and AIO, this is actually not going to fair well. But don't let me leave out that 4.1Ghz on this 2700X is actually it's most stable overclock. PBO won't even pass this frequency. So manual clocking it is.

Well I ramble a little. Pics or didn't happen right?

A little TEC frost there. That copper plate is directly on the core.