- Joined

- Jul 5, 2013

- Messages

- 28,257 (6.75/day)

A forum user recently asked about Coil Whine, which is the noise a choke coil sometimes makes as it operates. This is almost always a video card problem, but can happen on any other computer or electronics components employing a choke in it's circuitry, including motherboards & power supplies.

I have for decades been using a very easy, quick and, most importantly, permanent fix. This fix works 95% of the time to quiet the noise to the point that it is not audible more than 8inches/20cm away. The rest of the time, the noise is barely audible.

A word of caution! If your part is under warranty, you may wish to consider doing an RMA. Many(not all) manufacturers actually want the noisy part back so they can test and analyze it for re-engineering to improve future designs. If your part is NOT under warranty, read on...

What you need:

Any tools required to disassemble the part to access the choke coils in question.

One or more containers of thin liquid cyanoacrylate based glue, commonly known as "Super Glue".

The brand of super glue you choose is not important. The type is. The type must be of low viscosity so it can quickly wick into the empty spaces between the choke coil and the board it's soldered to. The applicator having a narrow tip nozzle is important as it will make applying the glue more precise. See below.

The glue of choice is the proper SuperGlue brand, but I also use the brand that can be found at Harbor Freight.

For this newest example, I'm using a Sparkle GeForce GTX560 2GB which has been noisy.

This card only has 5 main choke coils so sealing them will be easy.

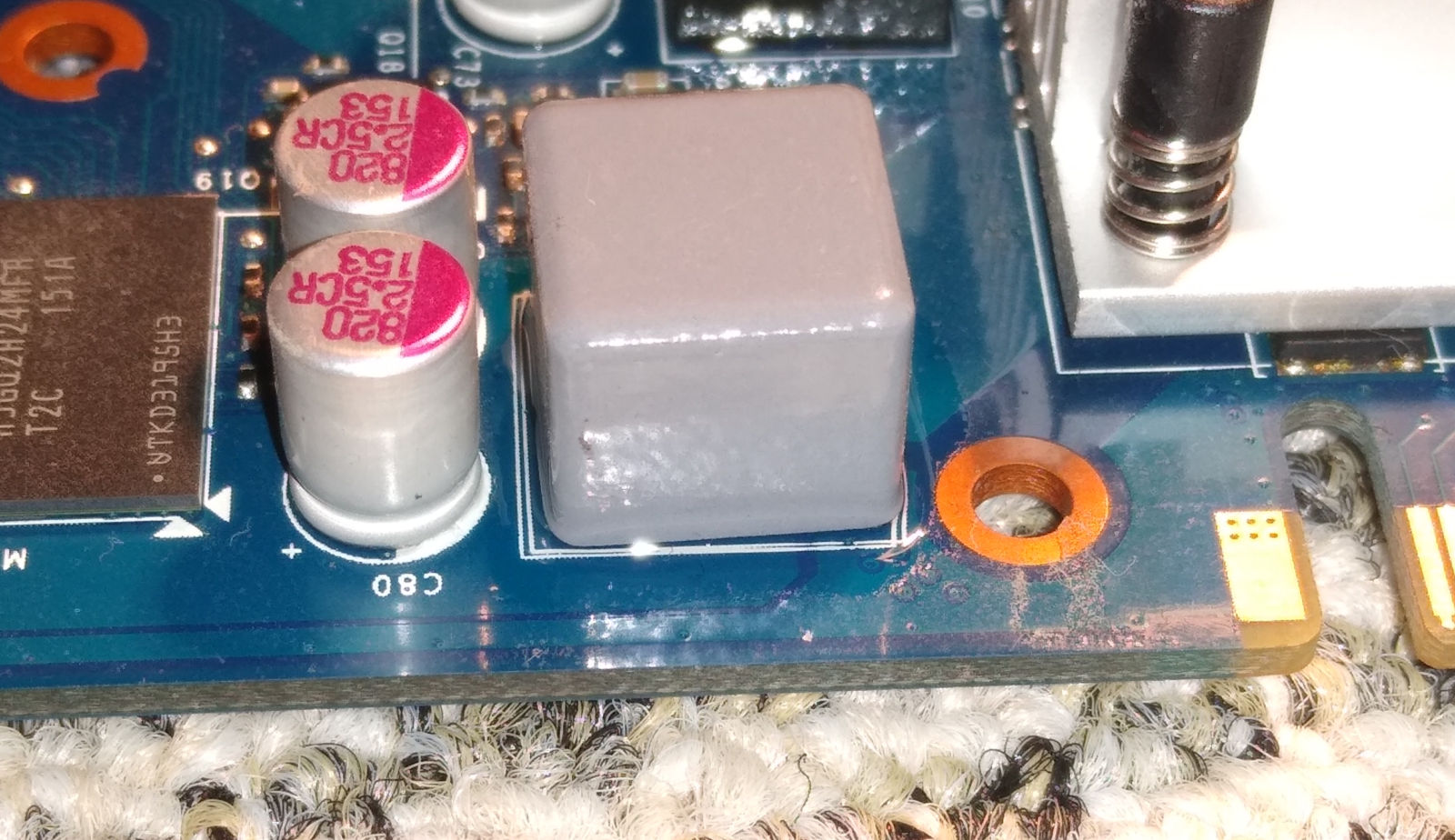

In this photo you can see how I'm applying the glue directly into the gap. Please note, the glue needs to be applied at multiple places around each choke housing shell, not just in one spot.

This photo shows how the glue has wicked itself into the gaps.

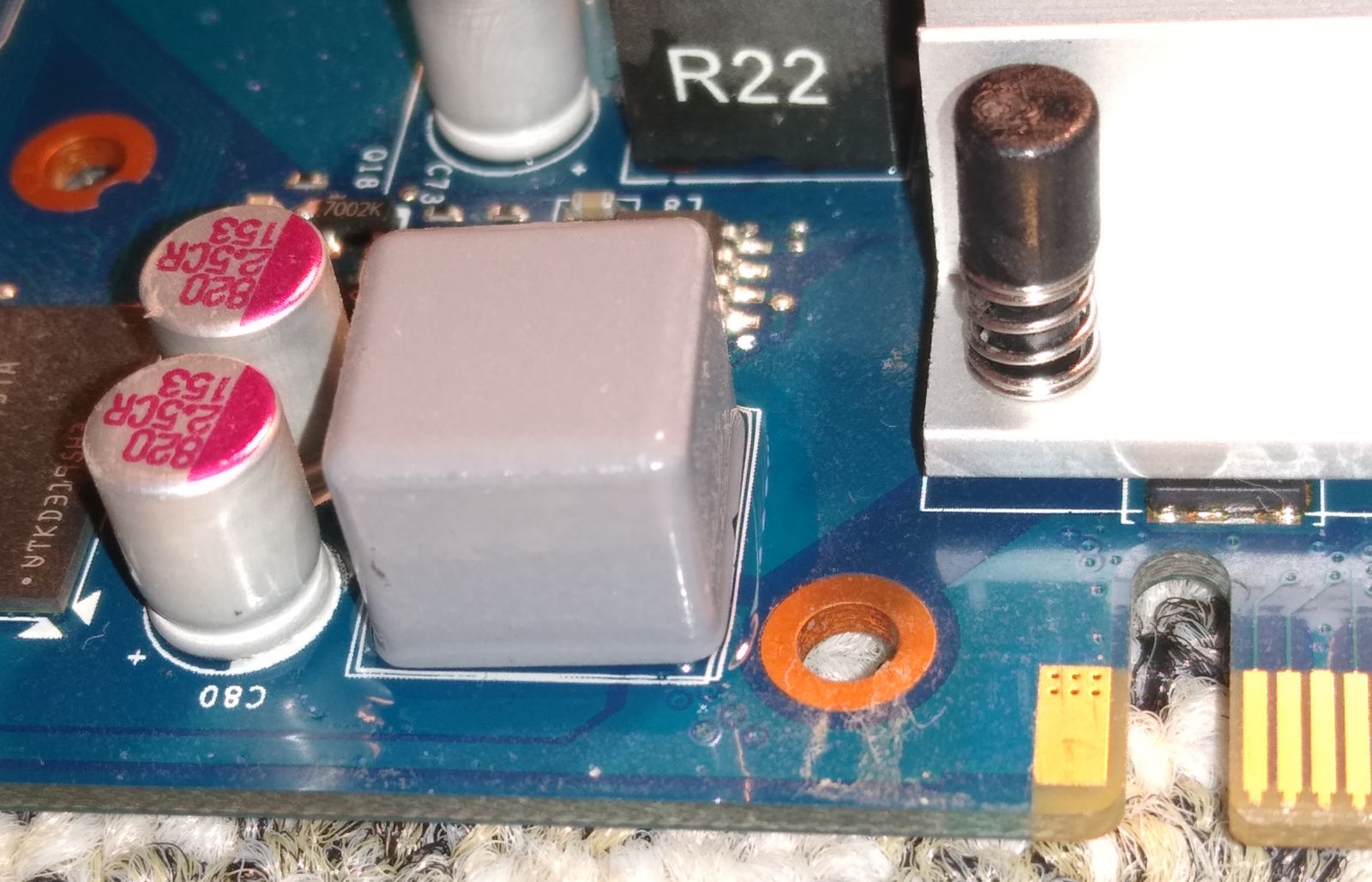

And here are two angles of the choke near the top of the card.

Notice how I've used a generous amount of glue to allow the wicking action to reach maximum effect.

It's important to use enough glue to completely wick the entire edge of the choke. Then you let it cure for at least an hour. While super glue generally sets between a few seconds to a few minutes, it still needs an hour or two to fully set and a day to fully cure. The card will be usable when the glue is set hard.

Once set the fix is complete and you're good to go! Put everything back together and test it out.

Please keep in mind: Choke Coil whine is not an exact science. Your experience and mileage might vary. Most cards will benefit from this method of noise dampening. Some more than others and there are cards that will have no effect at all, but such is less common.

A note about experience: Whether you're are an experience electronics tech or not, anyone can do this. However, if you're feeling a bit iffy, get some of the right type of glue and get a piece of junk electronics(thrift shop, yard sale or something you already have that's broken or you don't care about), take it apart and practice sealing parts on that PCB before starting. Post photo's here in the thread to show your work and ask for tips if you would like input. Expect to use some of your glue to practice, so buy extra.

Important Note:

After two reports and some research it has been discovered that the Loctite brand superglue found in many retail stores is a hybrid glue that has a consistency which falls inbetween gel types and the fluid types. As a superglue it might seem like a good choice but it is not. In this use-case-scenario, it is NOT recommended as it is not as fluidic as normal liquid superglue types and will not wick into the spaces between the choke coil housing and PCB! For the Loctite brand, Loctite 411 is the ideal product to use. However, Loctite is not the only brand that will work effectively

EDIT1: I have redone portions of this guide to give more details, info and better photo's. Thank's to the Mods for granting a perma-edit button so I can do ongoing updates to this thread!

EDIT2:

Adam Savage of Mythbuster's and YouTube fame has done a video that explains a lot about the properties and applications of CA glues.

Lot's of good info here, though where CA glue is applied here for coil noise dampening, the use of baking soda should NOT be used.

I have for decades been using a very easy, quick and, most importantly, permanent fix. This fix works 95% of the time to quiet the noise to the point that it is not audible more than 8inches/20cm away. The rest of the time, the noise is barely audible.

A word of caution! If your part is under warranty, you may wish to consider doing an RMA. Many(not all) manufacturers actually want the noisy part back so they can test and analyze it for re-engineering to improve future designs. If your part is NOT under warranty, read on...

What you need:

Any tools required to disassemble the part to access the choke coils in question.

One or more containers of thin liquid cyanoacrylate based glue, commonly known as "Super Glue".

The brand of super glue you choose is not important. The type is. The type must be of low viscosity so it can quickly wick into the empty spaces between the choke coil and the board it's soldered to. The applicator having a narrow tip nozzle is important as it will make applying the glue more precise. See below.

The glue of choice is the proper SuperGlue brand, but I also use the brand that can be found at Harbor Freight.

For this newest example, I'm using a Sparkle GeForce GTX560 2GB which has been noisy.

This card only has 5 main choke coils so sealing them will be easy.

In this photo you can see how I'm applying the glue directly into the gap. Please note, the glue needs to be applied at multiple places around each choke housing shell, not just in one spot.

This photo shows how the glue has wicked itself into the gaps.

And here are two angles of the choke near the top of the card.

Notice how I've used a generous amount of glue to allow the wicking action to reach maximum effect.

It's important to use enough glue to completely wick the entire edge of the choke. Then you let it cure for at least an hour. While super glue generally sets between a few seconds to a few minutes, it still needs an hour or two to fully set and a day to fully cure. The card will be usable when the glue is set hard.

Once set the fix is complete and you're good to go! Put everything back together and test it out.

Please keep in mind: Choke Coil whine is not an exact science. Your experience and mileage might vary. Most cards will benefit from this method of noise dampening. Some more than others and there are cards that will have no effect at all, but such is less common.

A note about experience: Whether you're are an experience electronics tech or not, anyone can do this. However, if you're feeling a bit iffy, get some of the right type of glue and get a piece of junk electronics(thrift shop, yard sale or something you already have that's broken or you don't care about), take it apart and practice sealing parts on that PCB before starting. Post photo's here in the thread to show your work and ask for tips if you would like input. Expect to use some of your glue to practice, so buy extra.

Important Note:

After two reports and some research it has been discovered that the Loctite brand superglue found in many retail stores is a hybrid glue that has a consistency which falls inbetween gel types and the fluid types. As a superglue it might seem like a good choice but it is not. In this use-case-scenario, it is NOT recommended as it is not as fluidic as normal liquid superglue types and will not wick into the spaces between the choke coil housing and PCB! For the Loctite brand, Loctite 411 is the ideal product to use. However, Loctite is not the only brand that will work effectively

EDIT1: I have redone portions of this guide to give more details, info and better photo's. Thank's to the Mods for granting a perma-edit button so I can do ongoing updates to this thread!

EDIT2:

Adam Savage of Mythbuster's and YouTube fame has done a video that explains a lot about the properties and applications of CA glues.

Lot's of good info here, though where CA glue is applied here for coil noise dampening, the use of baking soda should NOT be used.

Last edited: