ASUS has switched to a new liquid metal thermal compound for its entire 2020 ROG gaming laptop range, liquid metal has long been used in the enthusiast overclocking scene but this is the first time we've seen its widespread use in a mainstream laptop. ASUS had to develop new machinery to facilitate the application of the liquid metal thermal compound as traditionally it had only been applied manually which was not feasible in this case.

ASUS is utilizing the highly respected Conductonaut from Thermal Grizzly for the job to ensure the 10th Gen Intel Core processors powering the lineup stay cool, laptops featuring this new combination will be available from Q2. This press release from ASUS details their process in bringing liquid metal thermal compound to the gaming laptop market.

What is liquid metal?

Liquid metals have low melting points that render them fluid at room temperature. These alloys are highly conductive, so they're extremely effective at transferring thermal energy between surfaces like a processor die and heatsink. The benefits are well-established in overclocking and DIY circles, and internal testing reinforced the appeal for gaming laptops. Our engineers observed a 10~20°C reduction in temperatures depending on the CPU.

The improved thermal interface creates margin that can be used in different ways. Lower temperatures help processors sustain higher clock speeds for longer, and also prevent fans from ramping up to louder RPMs. The additional thermal headroom can also be used to reach even faster frequencies and higher performance.

Although liquid metal's properties are consistent regardless of the processor, our research indicates that Intel CPUs have the most to gain. The die is small, with heat concentrated in eight distinct regions of the chip. It's also surrounded by a safe zone on the CPU package that's free of surface-mounted components that don't get along with electrically conductive materials. We want to deploy liquid metal where it can have the biggest benefit and be the most reliable.

There are different kinds of liquid metal on the market. We use Conductonaut from Thermal Grizzly because it has a lower concentration of tin, which isn't as conductive as the gallium and indium that also make up the alloy. Rather than working closely with Thermal Grizzly like we do with other partners, we purchased initial quantities more casually to keep the project a secret. Not even Intel knew of our plans during development.

It's all in the wrist

Our research into liquid metal extended into how the compound's properties affect its viability in a manufacturing context. Liquid metal reacts with aluminium, which restricts the materials that can be used in heatsinks and on the production line. And unlike thicker thermal paste, liquid metal is truly fluid; it can easily go anywhere even when carefully squeezed onto the CPU. That's why applying liquid metal has traditionally been a painstaking process done by hand. While this approach works for individual builders and tuners dealing with one or two chips, automation is required to keep up with the volume of laptops that ROG produces.

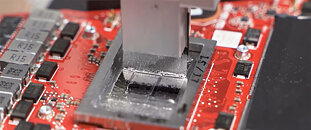

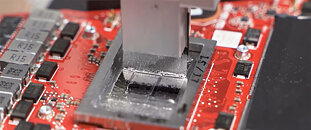

We developed a two-stage method that ensures the complete coverage required for optimal performance. The process begins by brushing the compound onto the die and concludes with additional injections to get the amount just right. Custom machinery performs both steps with mechanical precision.

Step one is essentially painting; a mechanized arm wets its brush in a container of liquid metal and then glides back and forth across the CPU. It performs exactly 17 passes, which our extensive testing determined is the ideal number for complete coverage. Rather than simply sliding back and forth, the machine mimics human motion by also moving vertically to add a subtle arc.

Cotton swabs are normally used to spread liquid metal by hand, but they absorb some of the compound and change shape as a result. We experimented with multiple vendors and more than 30 different brush designs to determine the best shape and material for long-term use. The final version is made of silicon, which doesn't deform or degrade with prolonged exposure.

To minimize accumulation on the edges of the processor, the initial brushing pass makes contact at a different point on the surface than subsequent strokes. The die also is set inside a stainless steel shim that prevents excess compound from spreading to the surrounding area. An earlier version of this shim fit onto the motherboard, but the latest iteration is small enough to sit directly on the CPU package, so it can be used for different laptops from the same generation.

Optimizing the dosage

We did a lot of internal testing to determine how much liquid metal is best. Too little reduces the efficiency of thermal transfer, but too much increases the likelihood of leakage and needlessly wastes an expensive material. The first stage doesn't apply enough, so a second machine injects more compound at two points on the die. The surface tension created by the initial coat helps spread the additional material without subsequent brushing.

Finding the right components for the second stage was one of the most challenging aspects of the project. Although we were able to use off-the-shelf parts, it was extremely difficult to source ones capable of not only housing liquid metal, but also reliably dispensing a precise dose. The syringe and pump are made of stainless steel to avoid reacting with the compound.

Low viscosity makes liquid metal much more mobile than thicker thermal paste. To keep it from seeping out and shorting adjacent circuitry, we created a special sponge that surrounds the die. This bespoke barrier fits into an incredibly slim space between the heatsink and CPU package that's only 0.1 mm tall—essentially the height of the die itself. We spent a lot of time balancing the thickness and density of the sponge to ensure containment without compromising contact between the heatsink and processor.

Intel CPUs have a restricted area around the die that is completely free of capacitors. The sponge neatly fills this space, but other processors occupy the same region with surface-mounted circuitry that's prone to shorting upon contact with the conductive compound. We're currently exploring insulating techniques to prevent the problem. They show promise but aren't yet ready for mass production.

View at TechPowerUp Main Site

ASUS is utilizing the highly respected Conductonaut from Thermal Grizzly for the job to ensure the 10th Gen Intel Core processors powering the lineup stay cool, laptops featuring this new combination will be available from Q2. This press release from ASUS details their process in bringing liquid metal thermal compound to the gaming laptop market.

What is liquid metal?

Liquid metals have low melting points that render them fluid at room temperature. These alloys are highly conductive, so they're extremely effective at transferring thermal energy between surfaces like a processor die and heatsink. The benefits are well-established in overclocking and DIY circles, and internal testing reinforced the appeal for gaming laptops. Our engineers observed a 10~20°C reduction in temperatures depending on the CPU.

The improved thermal interface creates margin that can be used in different ways. Lower temperatures help processors sustain higher clock speeds for longer, and also prevent fans from ramping up to louder RPMs. The additional thermal headroom can also be used to reach even faster frequencies and higher performance.

Although liquid metal's properties are consistent regardless of the processor, our research indicates that Intel CPUs have the most to gain. The die is small, with heat concentrated in eight distinct regions of the chip. It's also surrounded by a safe zone on the CPU package that's free of surface-mounted components that don't get along with electrically conductive materials. We want to deploy liquid metal where it can have the biggest benefit and be the most reliable.

There are different kinds of liquid metal on the market. We use Conductonaut from Thermal Grizzly because it has a lower concentration of tin, which isn't as conductive as the gallium and indium that also make up the alloy. Rather than working closely with Thermal Grizzly like we do with other partners, we purchased initial quantities more casually to keep the project a secret. Not even Intel knew of our plans during development.

It's all in the wrist

Our research into liquid metal extended into how the compound's properties affect its viability in a manufacturing context. Liquid metal reacts with aluminium, which restricts the materials that can be used in heatsinks and on the production line. And unlike thicker thermal paste, liquid metal is truly fluid; it can easily go anywhere even when carefully squeezed onto the CPU. That's why applying liquid metal has traditionally been a painstaking process done by hand. While this approach works for individual builders and tuners dealing with one or two chips, automation is required to keep up with the volume of laptops that ROG produces.

We developed a two-stage method that ensures the complete coverage required for optimal performance. The process begins by brushing the compound onto the die and concludes with additional injections to get the amount just right. Custom machinery performs both steps with mechanical precision.

Step one is essentially painting; a mechanized arm wets its brush in a container of liquid metal and then glides back and forth across the CPU. It performs exactly 17 passes, which our extensive testing determined is the ideal number for complete coverage. Rather than simply sliding back and forth, the machine mimics human motion by also moving vertically to add a subtle arc.

Cotton swabs are normally used to spread liquid metal by hand, but they absorb some of the compound and change shape as a result. We experimented with multiple vendors and more than 30 different brush designs to determine the best shape and material for long-term use. The final version is made of silicon, which doesn't deform or degrade with prolonged exposure.

To minimize accumulation on the edges of the processor, the initial brushing pass makes contact at a different point on the surface than subsequent strokes. The die also is set inside a stainless steel shim that prevents excess compound from spreading to the surrounding area. An earlier version of this shim fit onto the motherboard, but the latest iteration is small enough to sit directly on the CPU package, so it can be used for different laptops from the same generation.

Optimizing the dosage

We did a lot of internal testing to determine how much liquid metal is best. Too little reduces the efficiency of thermal transfer, but too much increases the likelihood of leakage and needlessly wastes an expensive material. The first stage doesn't apply enough, so a second machine injects more compound at two points on the die. The surface tension created by the initial coat helps spread the additional material without subsequent brushing.

Finding the right components for the second stage was one of the most challenging aspects of the project. Although we were able to use off-the-shelf parts, it was extremely difficult to source ones capable of not only housing liquid metal, but also reliably dispensing a precise dose. The syringe and pump are made of stainless steel to avoid reacting with the compound.

Low viscosity makes liquid metal much more mobile than thicker thermal paste. To keep it from seeping out and shorting adjacent circuitry, we created a special sponge that surrounds the die. This bespoke barrier fits into an incredibly slim space between the heatsink and CPU package that's only 0.1 mm tall—essentially the height of the die itself. We spent a lot of time balancing the thickness and density of the sponge to ensure containment without compromising contact between the heatsink and processor.

Intel CPUs have a restricted area around the die that is completely free of capacitors. The sponge neatly fills this space, but other processors occupy the same region with surface-mounted circuitry that's prone to shorting upon contact with the conductive compound. We're currently exploring insulating techniques to prevent the problem. They show promise but aren't yet ready for mass production.

View at TechPowerUp Main Site