TheLostSwede

News Editor

- Joined

- Nov 11, 2004

- Messages

- 18,319 (2.46/day)

- Location

- Sweden

| System Name | Overlord Mk MLI |

|---|---|

| Processor | AMD Ryzen 7 7800X3D |

| Motherboard | Gigabyte X670E Aorus Master |

| Cooling | Noctua NH-D15 SE with offsets |

| Memory | 32GB Team T-Create Expert DDR5 6000 MHz @ CL30-34-34-68 |

| Video Card(s) | Gainward GeForce RTX 4080 Phantom GS |

| Storage | 1TB Solidigm P44 Pro, 2 TB Corsair MP600 Pro, 2TB Kingston KC3000 |

| Display(s) | Acer XV272K LVbmiipruzx 4K@160Hz |

| Case | Fractal Design Torrent Compact |

| Audio Device(s) | Corsair Virtuoso SE |

| Power Supply | be quiet! Pure Power 12 M 850 W |

| Mouse | Logitech G502 Lightspeed |

| Keyboard | Corsair K70 Max |

| Software | Windows 10 Pro |

| Benchmark Scores | https://valid.x86.fr/yfsd9w |

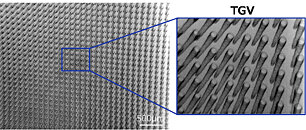

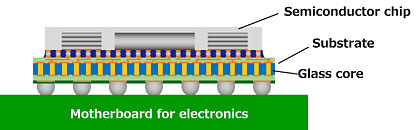

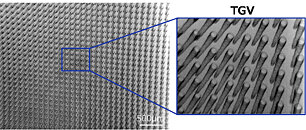

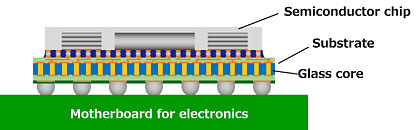

Dai Nippon Printing Co., Ltd. (DNP) has developed a Glass Core Substrate (GCS) targeting next-generation semiconductor packages. The new product replaces conventional resin substrates (ex. FC-BGA: Flip Chip-Ball Grid Array) with a glass substrate. Through the use of high-density Through Glass Via (TGV), it is now possible to provide a higher performance semiconductor package than that based on currently available technology. In addition, by adapting our panel manufacturing process, the new product can also support demands for high efficiency and large-scale substrate.

Features

Fine pitch and high reliability

The newly developed GCS includes a TGV necessary for electrically connecting the fine metal wiring configured on the front and back of the glass. It is a Conformal Type glass substrate in which a metal layer is adhered to the side walls of the via. Our new proprietary manufacturing method enhances the adhesion between glass and metal, which was difficult to achieve with conventional technology, to realize fine pitch and high reliability.

High aspect ratio and large-scale

The newly developed glass substrate has an aspect ratio of 9+, and maintains sufficient adhesive qualities to configure fine wiring. As there are few restrictions regarding the thickness of the glass substrate used, it is possible to boost the degree of freedom when designing warpage, rigidity, and flatness. It is also possible to accommodate package scalability by employing our panel manufacturing process.

Going Forward

In addition to the existing Filling Type glass substrate that fills the glass Via with copper, DNP is also promoting the scalability of the newly developed Conformal Type glass substrate to a panel size of 510 x 515 mm. We aim for sales of 5.0 billion yen in FY 2027.

View at TechPowerUp Main Site | Source

Features

Fine pitch and high reliability

The newly developed GCS includes a TGV necessary for electrically connecting the fine metal wiring configured on the front and back of the glass. It is a Conformal Type glass substrate in which a metal layer is adhered to the side walls of the via. Our new proprietary manufacturing method enhances the adhesion between glass and metal, which was difficult to achieve with conventional technology, to realize fine pitch and high reliability.

High aspect ratio and large-scale

The newly developed glass substrate has an aspect ratio of 9+, and maintains sufficient adhesive qualities to configure fine wiring. As there are few restrictions regarding the thickness of the glass substrate used, it is possible to boost the degree of freedom when designing warpage, rigidity, and flatness. It is also possible to accommodate package scalability by employing our panel manufacturing process.

Going Forward

In addition to the existing Filling Type glass substrate that fills the glass Via with copper, DNP is also promoting the scalability of the newly developed Conformal Type glass substrate to a panel size of 510 x 515 mm. We aim for sales of 5.0 billion yen in FY 2027.

View at TechPowerUp Main Site | Source