- Joined

- Oct 9, 2007

- Messages

- 47,655 (7.43/day)

- Location

- Dublin, Ireland

| System Name | RBMK-1000 |

|---|---|

| Processor | AMD Ryzen 7 5700G |

| Motherboard | Gigabyte B550 AORUS Elite V2 |

| Cooling | DeepCool Gammax L240 V2 |

| Memory | 2x 16GB DDR4-3200 |

| Video Card(s) | Galax RTX 4070 Ti EX |

| Storage | Samsung 990 1TB |

| Display(s) | BenQ 1440p 60 Hz 27-inch |

| Case | Corsair Carbide 100R |

| Audio Device(s) | ASUS SupremeFX S1220A |

| Power Supply | Cooler Master MWE Gold 650W |

| Mouse | ASUS ROG Strix Impact |

| Keyboard | Gamdias Hermes E2 |

| Software | Windows 11 Pro |

"Navi 4C" is a future high-end GPU from AMD that will likely not see the light of day, as the company is pivoting away from the high-end GPU segment with its next RDNA4 generation. For AMD to continue investing in the development of this GPU, the gaming graphics card segment should have posted better sales, especially in the high-end, which it didn't. Moore's Law is Dead scored details of what could have been a fascinating technological endeavor for AMD, in building a highly disaggregated GPU.

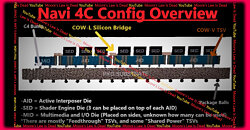

AMD's current "Navi 31" GPU sees a disaggregation of the main logic components of the GPU that benefit from the latest 5 nm foundry node to be located in a central Graphics Compute Die; surrounded by up to six little chiplets built on the older 6 nm foundry node, which contain segments of the GPU's Infinity Cache memory, and its memory interface—hence the name memory cache die. With "Navi 4C," AMD had intended to further disaggregate the GPU, identifying even more components on the GCD that can be spun out into chiplets; as well as breaking up the shader engines themselves into smaller self-contained chiplets (smaller dies == greater yields and lower foundry costs).

The way AMD would go about creating "Navi 4C" would be using a vast array of packaging innovations that ensure the numerous kinds of chiplets talk to each other with as little latency as possible, as if they were parts of a whole monolithic die.

Assuming AMD had continued to use GDDR6 and not the newer GDDR7 memory standard, the company would have likely retained 6 nm MCDs from the current generation, to provide video memory interface and last-level cache to the GPU, minimizing R&D costs, and gaining from the further reduced foundry costs for the 6 nm node.

AMD identified the GPU's media acceleration engine, and Radiance Display Engine ripe for the next round of disaggregation. Although media acceleration engines are logic components, these are fixed function hardware, as are the display engines; and can likely make do with older foundry nodes. The media acceleration and display engine would be spun off into a separate chiplet called MID (media and I/O die). At this point we don't know if AMD would've gone with 6 nm or a newer node for the MID, but given that the company is able to pack the latest media and display I/O features onto the 6 nm "Navi 33" monolithic silicon, it's possible that the company would go with the older node.

Much of the semiconductor engineering muscle is centered on what happens to the most critical number-crunching machinery of the GPU, the Shader Engines. Apparently, AMD figured out that each Shader Engine, consisting of a fixed number of workgroup processors (WGPs), could be spun out into chiplets, called SEDs (shader engine dies). These would be built on an advanced foundry node. Given that NVIDIA is building its next-gen "Blackwell" GPUs on 3 nm, it's quite possible that AMD uses the same node for the SEDs.

The SEDs are seated on active interposer dies (AIDs). An interposer in general, is a silicon die whose sole purpose is to facilitate high-density microscopic wiring between chiplets stacked on top of it, with wiring densities that otherwise wouldn't be possible through fiberglass substrate. The "active" part of the AID refers to the ability of the interposer not just to facilitate wiring among dies stacked on top and to the substrate below, but also neighboring AIDs. For this purpose, TSMC innovated the COW-L (chip-on-wafer-L) bridges.

These are tiny silicon dies designed for inter-AID high-density wiring, and is how a mesh of AIDs talk to each other, and to the MID. As for how they communicate with the MCDs, remains to be seen. The current generation of MCDs are connected with the GCD using Infinity Fan-out Links—a high-density wiring method that makes do with the fiberglass substrate as the medium, instead of silicon. Should AMD be using another method to connect the MCDs, it would mean that the company is using a newer generation of them. Besides COW-L bridges, AMD is also leveraging TSMC's COW-V TSVs (through-silicon via) innovations for connecting the SEDs to the package substrate (for power and other I/O).

Alas, it's highly unlikely that "Navi 4C" will ever get off the drawing board. AMD has already implemented many of these packaging innovations with its latest MI300 compute processor based on the CDNA3 architecture, and it would have been incredible to see them in the gaming graphics segment, however, basic economics prevent AMD from investing in further development of the "Navi 4C." The gaming graphics card market is in its biggest slump since the late 2010s, and the enthusiast-class GPU caters to a niche market.

The current market conditions are a far cry from 2021, when the crypto-currency mining gold-rush had incentivized GPU manufacturers to make bigger GPUs. AMD is rumored to have mistimed the launch of its RX 6950 XT GPU toward the tail-end of the crypto boom. By that point, "Navi 31" had reached an advanced level of development and was ready to enter mass-production. The company now probably finds itself unable to justify the cost of development for "Navi 4C" beyond the concepts in this article, unless the market undergoes another dramatic upsurge in demand at the high-end.

View at TechPowerUp Main Site | Source

AMD's current "Navi 31" GPU sees a disaggregation of the main logic components of the GPU that benefit from the latest 5 nm foundry node to be located in a central Graphics Compute Die; surrounded by up to six little chiplets built on the older 6 nm foundry node, which contain segments of the GPU's Infinity Cache memory, and its memory interface—hence the name memory cache die. With "Navi 4C," AMD had intended to further disaggregate the GPU, identifying even more components on the GCD that can be spun out into chiplets; as well as breaking up the shader engines themselves into smaller self-contained chiplets (smaller dies == greater yields and lower foundry costs).

The way AMD would go about creating "Navi 4C" would be using a vast array of packaging innovations that ensure the numerous kinds of chiplets talk to each other with as little latency as possible, as if they were parts of a whole monolithic die.

Assuming AMD had continued to use GDDR6 and not the newer GDDR7 memory standard, the company would have likely retained 6 nm MCDs from the current generation, to provide video memory interface and last-level cache to the GPU, minimizing R&D costs, and gaining from the further reduced foundry costs for the 6 nm node.

AMD identified the GPU's media acceleration engine, and Radiance Display Engine ripe for the next round of disaggregation. Although media acceleration engines are logic components, these are fixed function hardware, as are the display engines; and can likely make do with older foundry nodes. The media acceleration and display engine would be spun off into a separate chiplet called MID (media and I/O die). At this point we don't know if AMD would've gone with 6 nm or a newer node for the MID, but given that the company is able to pack the latest media and display I/O features onto the 6 nm "Navi 33" monolithic silicon, it's possible that the company would go with the older node.

Much of the semiconductor engineering muscle is centered on what happens to the most critical number-crunching machinery of the GPU, the Shader Engines. Apparently, AMD figured out that each Shader Engine, consisting of a fixed number of workgroup processors (WGPs), could be spun out into chiplets, called SEDs (shader engine dies). These would be built on an advanced foundry node. Given that NVIDIA is building its next-gen "Blackwell" GPUs on 3 nm, it's quite possible that AMD uses the same node for the SEDs.

The SEDs are seated on active interposer dies (AIDs). An interposer in general, is a silicon die whose sole purpose is to facilitate high-density microscopic wiring between chiplets stacked on top of it, with wiring densities that otherwise wouldn't be possible through fiberglass substrate. The "active" part of the AID refers to the ability of the interposer not just to facilitate wiring among dies stacked on top and to the substrate below, but also neighboring AIDs. For this purpose, TSMC innovated the COW-L (chip-on-wafer-L) bridges.

These are tiny silicon dies designed for inter-AID high-density wiring, and is how a mesh of AIDs talk to each other, and to the MID. As for how they communicate with the MCDs, remains to be seen. The current generation of MCDs are connected with the GCD using Infinity Fan-out Links—a high-density wiring method that makes do with the fiberglass substrate as the medium, instead of silicon. Should AMD be using another method to connect the MCDs, it would mean that the company is using a newer generation of them. Besides COW-L bridges, AMD is also leveraging TSMC's COW-V TSVs (through-silicon via) innovations for connecting the SEDs to the package substrate (for power and other I/O).

Alas, it's highly unlikely that "Navi 4C" will ever get off the drawing board. AMD has already implemented many of these packaging innovations with its latest MI300 compute processor based on the CDNA3 architecture, and it would have been incredible to see them in the gaming graphics segment, however, basic economics prevent AMD from investing in further development of the "Navi 4C." The gaming graphics card market is in its biggest slump since the late 2010s, and the enthusiast-class GPU caters to a niche market.

The current market conditions are a far cry from 2021, when the crypto-currency mining gold-rush had incentivized GPU manufacturers to make bigger GPUs. AMD is rumored to have mistimed the launch of its RX 6950 XT GPU toward the tail-end of the crypto boom. By that point, "Navi 31" had reached an advanced level of development and was ready to enter mass-production. The company now probably finds itself unable to justify the cost of development for "Navi 4C" beyond the concepts in this article, unless the market undergoes another dramatic upsurge in demand at the high-end.

View at TechPowerUp Main Site | Source