T0@st

News Editor

- Joined

- Mar 7, 2023

- Messages

- 2,920 (3.79/day)

- Location

- South East, UK

| System Name | The TPU Typewriter |

|---|---|

| Processor | AMD Ryzen 5 5600 (non-X) |

| Motherboard | GIGABYTE B550M DS3H Micro ATX |

| Cooling | DeepCool AS500 |

| Memory | Kingston Fury Renegade RGB 32 GB (2 x 16 GB) DDR4-3600 CL16 |

| Video Card(s) | PowerColor Radeon RX 7800 XT 16 GB Hellhound OC |

| Storage | Samsung 980 Pro 1 TB M.2-2280 PCIe 4.0 X4 NVME SSD |

| Display(s) | Lenovo Legion Y27q-20 27" QHD IPS monitor |

| Case | GameMax Spark M-ATX (re-badged Jonsbo D30) |

| Audio Device(s) | FiiO K7 Desktop DAC/Amp + Philips Fidelio X3 headphones, or ARTTI T10 Planar IEMs |

| Power Supply | ADATA XPG CORE Reactor 650 W 80+ Gold ATX |

| Mouse | Roccat Kone Pro Air |

| Keyboard | Cooler Master MasterKeys Pro L |

| Software | Windows 10 64-bit Home Edition |

"The Earth is Blue," said Yuri Gagarin, the first human to journey into space. With two-thirds of its surface covered in water, Earth is a planet that exuberates its blue radiance in the dark space. However, today, the scarcity of water is a challenge that planet Earth is confronted with. For some, this may be hard to understand. What happened to our blue planet Earth? To put in numbers, more than 97% of the water on Earth consists of seawater, with another 2% locked in ice caps. That only leaves a mere 1% of water available for our daily use. The problem lies in the fact that this 1% of water is gradually becoming scarcer due to reasons such as climate change, environmental pollution, and population growth, leading to increased water stress. 'Water stress' is quantified by the proportion of water demand to the available water resources on an annual basis, indicating the severity of water scarcity as the stress index rises. Higher stress indexes signify experiencing severe water scarcity.

The semiconductor ecosystem, unsustainable without water

Because water stress issues transcend national boundaries, various stakeholders including international organizations and governments work to negotiate water resource management strategies and promote collaboration. UN designates March 22nd as an annual "World Water Day" to raise awareness about the severity of water scarcity running various campaigns. Now, it's imperative for companies to also take responsibility for the water resources given and pursue sustainable management.

The semiconductor industry is no exception to this matter. In various stages of semiconductor manufacturing processes, a significant amount of water is utilized, especially in the process of wafer cleaning where highly purified ultrapure water is employed. Ultrapure water refers to water that has been purified to remove impurities such as fine particles and microorganisms, leaving only hydrogen and oxygen molecules that constitute water in general. Even minuscule impurities can impact chip production and quality, hence the necessity for ultra-pure water. It's so crucial that ultra-pure water is often referred to as the 'lifeblood' of semiconductors. And so, to produce semiconductors, including the use of ultra-pure water, tens of thousands of tons of water are needed daily, which makes water resource management a critical task.

Samsung Semiconductor's Solution: 'Collaboration' and 'Technology'

In response to the surging demand for semiconductors, Samsung Semiconductor is also planning to expand its production lines. By 2030, it is projected that the industrial water required for its facilities will more than double from the current amount. However, Samsung Semiconductor has been actively exploring various solutions to stably secure industrial water while minimizing water intake increase.

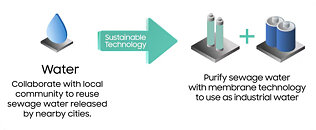

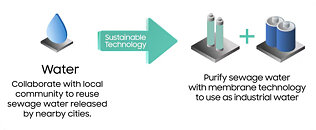

1) Sewage Water Reuse

There are two ways to secure industrial water, one is to extract water from nature and other, reuse water that has already been used. With that, Samsung Semiconductor plans to reuse public sewage water by converting them as industrial water. To achieve this, in November of 2022, Samsung Semiconductor signed a memorandum of understanding (MOU) for sewage treatment water reuse plan with the Ministry of Environment, Gyeonggi Province, and five city (Suwon, Yongin, Hwaseong, Pyeongtaek, and Osan) bodies, along with the Korea Water Resources Corporation and the Korea Environment Corporation. This plan will help supply up to approximately 400,000tons of daily water, reaching a staggering 1.5 billion tons annually. The water procured from public sewage is expected to contribute significantly to mitigating water stress by ensuring maximum availability of industrial water without depleting natural water sources.

2) Membrane Technology

To utilize sewage reused water for industrial purposes as previously described, membrane technology is necessary. Membrane technology is one of the advanced filtration technologies used for purifying water. Membranes contain extremely tiny pores, allowing molecules smaller than water to pass through while filtering out larger substances such as minerals, microbes, and various impurities.

In addition, Samsung Semiconductor strives to maximize water reuse rates through routine conservation activities such as optimizing operational practices, replacing outdated equipment, as well as structural improvement initiatives like refining manufacturing processes and establishing recycling systems to restrain water intake increase.

Awarded the highest level of AWS certification with innovative technology

Samsung Semiconductors' thorough water management capabilities have been internationally recognized. The Hwaseong, Giheung and Pyeongtaek site, Korea, as well as Xi'an site, China have received the highest rating of 'Platinum' certification from the Alliance for Water Stewardship (AWS), an organization that evaluates business site water management capabilities. AWS certification is divided into three levels: Platinum, Gold, and Core, based on the evaluation of a total of 100 criteria, including stable water management, management of water pollution substances, and impacts on watershed aquatic ecosystems. Obtaining a Platinum rating on the first attempt is very unusual given the rigorous verification process, which is a testament to Samsung Semiconductors' excellence in water resource management, demonstrating exceptional performance even per international standards.

Samsung Semiconductor aims to lead the semiconductor ecosystem by developing and implementing sustainable technologies to achieve its 'Keep water withdrawal to 2021 levels in 2030' goal.

View at TechPowerUp Main Site | Source

The semiconductor ecosystem, unsustainable without water

Because water stress issues transcend national boundaries, various stakeholders including international organizations and governments work to negotiate water resource management strategies and promote collaboration. UN designates March 22nd as an annual "World Water Day" to raise awareness about the severity of water scarcity running various campaigns. Now, it's imperative for companies to also take responsibility for the water resources given and pursue sustainable management.

The semiconductor industry is no exception to this matter. In various stages of semiconductor manufacturing processes, a significant amount of water is utilized, especially in the process of wafer cleaning where highly purified ultrapure water is employed. Ultrapure water refers to water that has been purified to remove impurities such as fine particles and microorganisms, leaving only hydrogen and oxygen molecules that constitute water in general. Even minuscule impurities can impact chip production and quality, hence the necessity for ultra-pure water. It's so crucial that ultra-pure water is often referred to as the 'lifeblood' of semiconductors. And so, to produce semiconductors, including the use of ultra-pure water, tens of thousands of tons of water are needed daily, which makes water resource management a critical task.

Samsung Semiconductor's Solution: 'Collaboration' and 'Technology'

In response to the surging demand for semiconductors, Samsung Semiconductor is also planning to expand its production lines. By 2030, it is projected that the industrial water required for its facilities will more than double from the current amount. However, Samsung Semiconductor has been actively exploring various solutions to stably secure industrial water while minimizing water intake increase.

1) Sewage Water Reuse

There are two ways to secure industrial water, one is to extract water from nature and other, reuse water that has already been used. With that, Samsung Semiconductor plans to reuse public sewage water by converting them as industrial water. To achieve this, in November of 2022, Samsung Semiconductor signed a memorandum of understanding (MOU) for sewage treatment water reuse plan with the Ministry of Environment, Gyeonggi Province, and five city (Suwon, Yongin, Hwaseong, Pyeongtaek, and Osan) bodies, along with the Korea Water Resources Corporation and the Korea Environment Corporation. This plan will help supply up to approximately 400,000tons of daily water, reaching a staggering 1.5 billion tons annually. The water procured from public sewage is expected to contribute significantly to mitigating water stress by ensuring maximum availability of industrial water without depleting natural water sources.

2) Membrane Technology

To utilize sewage reused water for industrial purposes as previously described, membrane technology is necessary. Membrane technology is one of the advanced filtration technologies used for purifying water. Membranes contain extremely tiny pores, allowing molecules smaller than water to pass through while filtering out larger substances such as minerals, microbes, and various impurities.

In addition, Samsung Semiconductor strives to maximize water reuse rates through routine conservation activities such as optimizing operational practices, replacing outdated equipment, as well as structural improvement initiatives like refining manufacturing processes and establishing recycling systems to restrain water intake increase.

Awarded the highest level of AWS certification with innovative technology

Samsung Semiconductors' thorough water management capabilities have been internationally recognized. The Hwaseong, Giheung and Pyeongtaek site, Korea, as well as Xi'an site, China have received the highest rating of 'Platinum' certification from the Alliance for Water Stewardship (AWS), an organization that evaluates business site water management capabilities. AWS certification is divided into three levels: Platinum, Gold, and Core, based on the evaluation of a total of 100 criteria, including stable water management, management of water pollution substances, and impacts on watershed aquatic ecosystems. Obtaining a Platinum rating on the first attempt is very unusual given the rigorous verification process, which is a testament to Samsung Semiconductors' excellence in water resource management, demonstrating exceptional performance even per international standards.

Samsung Semiconductor aims to lead the semiconductor ecosystem by developing and implementing sustainable technologies to achieve its 'Keep water withdrawal to 2021 levels in 2030' goal.

View at TechPowerUp Main Site | Source