- Joined

- Jan 27, 2006

- Messages

- 2,571 (0.36/day)

Edit: nevermind, this is of course not just about review CPU's...

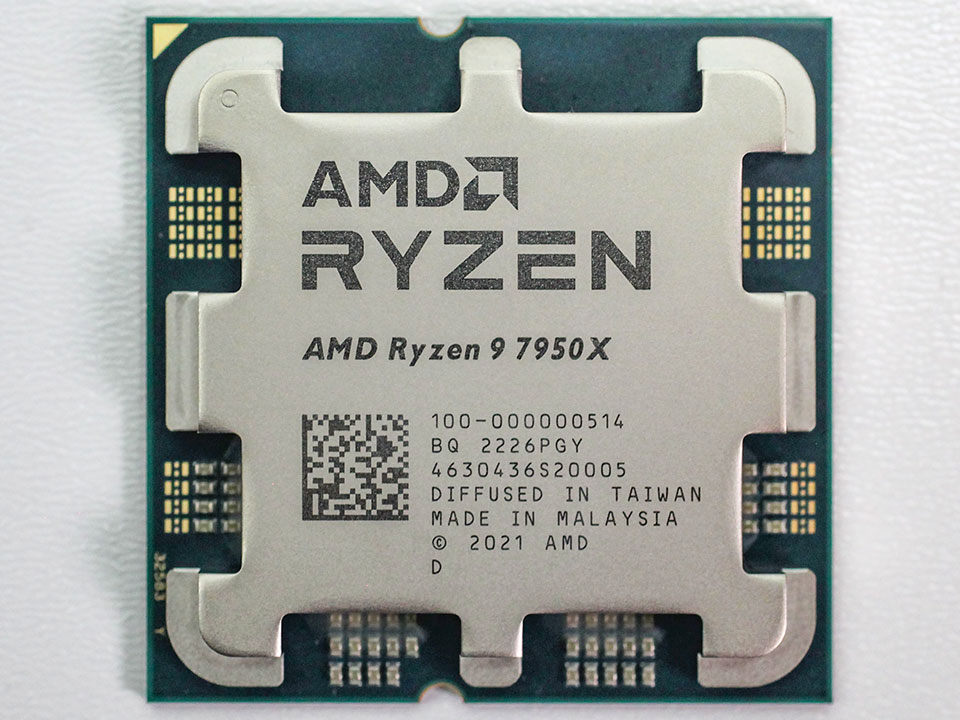

That's not a new thing.The copyright on that chip also says 2023. I appreciate the naming convention was probably listed then, but it's still odd to me.

Last edited:

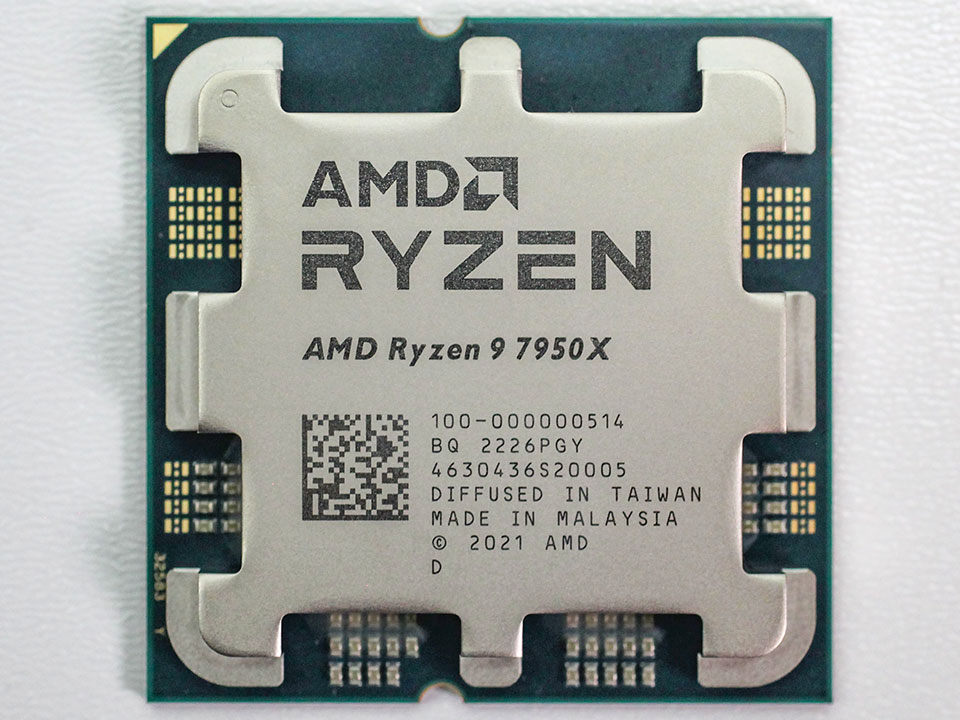

It looks that certain someone had a few beers more than it should before started working on laser engraving machine

It looks that certain someone had a few beers more than it should before started working on laser engraving machine