- Joined

- May 21, 2024

- Messages

- 536 (3.75/day)

E&R Engineering Corp. hosted an event on August 28, 2024, in Taipei, Taiwan, where they launched the "E-Core System." This initiative, a combination of "E&R" and "Glass Core" inspired by the sound of "Ecosystem," led to the establishment of the "Glass Substrate Supplier E-Core System Alliance." The alliance aims to combine expertise to promote comprehensive solutions, providing equipment and materials for next-generation advanced packaging with glass substrates to both domestic and international customers.

E&R's E-Core Alliance includes Manz AG, Scientech for wet etching, HYAWEI OPTRONICS for AOI optical inspection, Lincotec, STK Corp., Skytech, Group Up for sputtering and ABF lamination equipment, and other key component suppliers such as HIWIN, HIWIN MIKROSYSTEM, Keyence Taiwan, Mirle Group, ACE PILLAR CHYI DING), and Coherent.

E&R will continue leading the development of glass substrate technology in Taiwan, optimizing processes, and collaborating with more industry partners to achieve excellence.

With the rapid growth in demand for AI chips, high-frequency, and high-speed communication devices, glass substrates in advanced packaging technologies are becoming increasingly important. Compared to the widespread use of copper foil substrates, glass substrates offer higher wiring density and better signal performance. Additionally, glass provides extremely high flatness and can withstand high temperatures and voltages, making it an ideal replacement for traditional substrates.

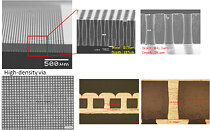

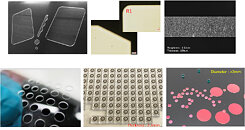

The glass substrate process involves glass metallization, the subsequent ABF (Ajinomoto Build-up Film) lamination, and final substrate cutting. Key steps in glass metallization include TGV (Through-Glass Via), wet etching, AOI (Automated Optical Inspection), sputtering, and plating. These glass substrates measure 515×510 mm, representing a new process in semiconductor and substrate manufacturing.

The critical aspect of glass substrate technology is the first step—glass laser modification (TGV). Although introduced over a decade ago, its speed had not met mass production requirements, achieving only 10 to 50 vias per second, limiting the market impact of glass substrates. E&R Engineering Corp has been working with a North American IDM customer for the past five years to develop glass laser modification TGV technology. Last year, the process passed validation, with E&R mastering key technology, now achieving up to 8,000 vias per second for fixed patterns (matrix layouts) or 600 to 1,000 vias per second for customized patterns (random layouts), with an accuracy of +/- 5 μm, meeting the 3 sigma standard. This breakthrough has finally enabled glass substrates to reach mass production.

View at TechPowerUp Main Site | Source

E&R's E-Core Alliance includes Manz AG, Scientech for wet etching, HYAWEI OPTRONICS for AOI optical inspection, Lincotec, STK Corp., Skytech, Group Up for sputtering and ABF lamination equipment, and other key component suppliers such as HIWIN, HIWIN MIKROSYSTEM, Keyence Taiwan, Mirle Group, ACE PILLAR CHYI DING), and Coherent.

E&R will continue leading the development of glass substrate technology in Taiwan, optimizing processes, and collaborating with more industry partners to achieve excellence.

With the rapid growth in demand for AI chips, high-frequency, and high-speed communication devices, glass substrates in advanced packaging technologies are becoming increasingly important. Compared to the widespread use of copper foil substrates, glass substrates offer higher wiring density and better signal performance. Additionally, glass provides extremely high flatness and can withstand high temperatures and voltages, making it an ideal replacement for traditional substrates.

The glass substrate process involves glass metallization, the subsequent ABF (Ajinomoto Build-up Film) lamination, and final substrate cutting. Key steps in glass metallization include TGV (Through-Glass Via), wet etching, AOI (Automated Optical Inspection), sputtering, and plating. These glass substrates measure 515×510 mm, representing a new process in semiconductor and substrate manufacturing.

The critical aspect of glass substrate technology is the first step—glass laser modification (TGV). Although introduced over a decade ago, its speed had not met mass production requirements, achieving only 10 to 50 vias per second, limiting the market impact of glass substrates. E&R Engineering Corp has been working with a North American IDM customer for the past five years to develop glass laser modification TGV technology. Last year, the process passed validation, with E&R mastering key technology, now achieving up to 8,000 vias per second for fixed patterns (matrix layouts) or 600 to 1,000 vias per second for customized patterns (random layouts), with an accuracy of +/- 5 μm, meeting the 3 sigma standard. This breakthrough has finally enabled glass substrates to reach mass production.

View at TechPowerUp Main Site | Source