T0@st

News Editor

- Joined

- Mar 7, 2023

- Messages

- 2,541 (3.50/day)

- Location

- South East, UK

Intel's Platform Engineering and Client Segments groups are actively looking into ways of reducing computer e-waste, and (in parallel) enhance product repairability. The company's newly proposed "Modular PC Design" is set to take a "sustainable approach" across three key modularity levels: factory, field and user. Team Blue's blog post goes into great detail about revised laptop and mini-PC designs—with the "right-to-repair" movement serving as a major influence. Many "consumer activists and environmental groups" have advocated for improvements in personal computer design—Intel appears to be listening, but a firm release timeline has not been set.

Intel's proposed new standards will revolve around repairability and upgradability—as explained in their blog: "the right-to-repair emphasizes the importance of being able to fix and upgrade PCs on one's own. Improving repairability requires fundamental changes starting from the design methodology." Team Blue's Modular PC program—for laptops—breaks away from the tradition of utilizing an "all-in-one motherboard." A reference diagram shows off three internal modules: a motherboard package and two "universal" left and right I/O units. These separate boards can be: "utilized across various platforms or market segments leads to cost savings by streamlining the duration of the design cycle and minimizing the engineering investment required. The I/O boards for Premium Modular designs are engineered to be common between the fan-less Thin & Light system, which operates within a 10 W power envelope, and the premium fanned designs, which function within a 20 W (single fan) and 30 W (dual fan, Wi-Fi only SKU) power envelope." Framework recently celebrated its fifth year of operation—its modular laptop designs have seemingly "inspired" a few copycats.

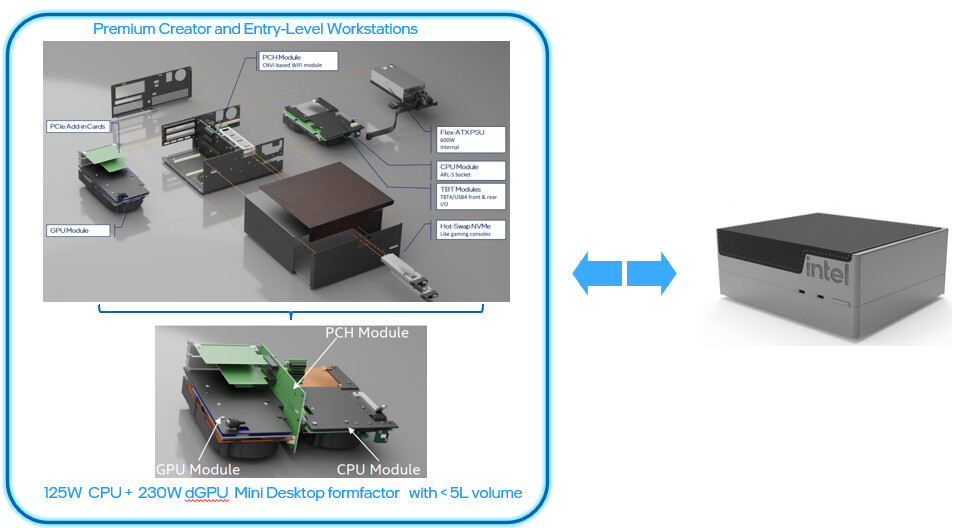

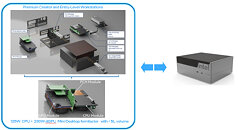

Intel's proposed "Desktop Modular PC Architecture" focuses on compact form factor premium creator and entry-level workstation market segments. Many "traditional" mini-PC systems are inherently difficult to upgrade and/or repair, due to components being soldered onto logic boards. Again, Team Blue's proposed solution compartmentalizes the fundamentals into separate pieces: CPU module, GPU module, and Platform Controller Hub (PCH) module. Their blog boasts this concept: "elevating modularity to the next level by introducing subsystem-level replaceable modules, such as a Type-C connector on an FPC (Flexible Printed Circuit) and a Type-C connector on an M.2 PCB. These modules significantly reduce repair costs and simplify the repair process in the event of port or connector damage at the end-user level."

View at TechPowerUp Main Site | Source

Intel's proposed new standards will revolve around repairability and upgradability—as explained in their blog: "the right-to-repair emphasizes the importance of being able to fix and upgrade PCs on one's own. Improving repairability requires fundamental changes starting from the design methodology." Team Blue's Modular PC program—for laptops—breaks away from the tradition of utilizing an "all-in-one motherboard." A reference diagram shows off three internal modules: a motherboard package and two "universal" left and right I/O units. These separate boards can be: "utilized across various platforms or market segments leads to cost savings by streamlining the duration of the design cycle and minimizing the engineering investment required. The I/O boards for Premium Modular designs are engineered to be common between the fan-less Thin & Light system, which operates within a 10 W power envelope, and the premium fanned designs, which function within a 20 W (single fan) and 30 W (dual fan, Wi-Fi only SKU) power envelope." Framework recently celebrated its fifth year of operation—its modular laptop designs have seemingly "inspired" a few copycats.

Intel's proposed "Desktop Modular PC Architecture" focuses on compact form factor premium creator and entry-level workstation market segments. Many "traditional" mini-PC systems are inherently difficult to upgrade and/or repair, due to components being soldered onto logic boards. Again, Team Blue's proposed solution compartmentalizes the fundamentals into separate pieces: CPU module, GPU module, and Platform Controller Hub (PCH) module. Their blog boasts this concept: "elevating modularity to the next level by introducing subsystem-level replaceable modules, such as a Type-C connector on an FPC (Flexible Printed Circuit) and a Type-C connector on an M.2 PCB. These modules significantly reduce repair costs and simplify the repair process in the event of port or connector damage at the end-user level."

View at TechPowerUp Main Site | Source