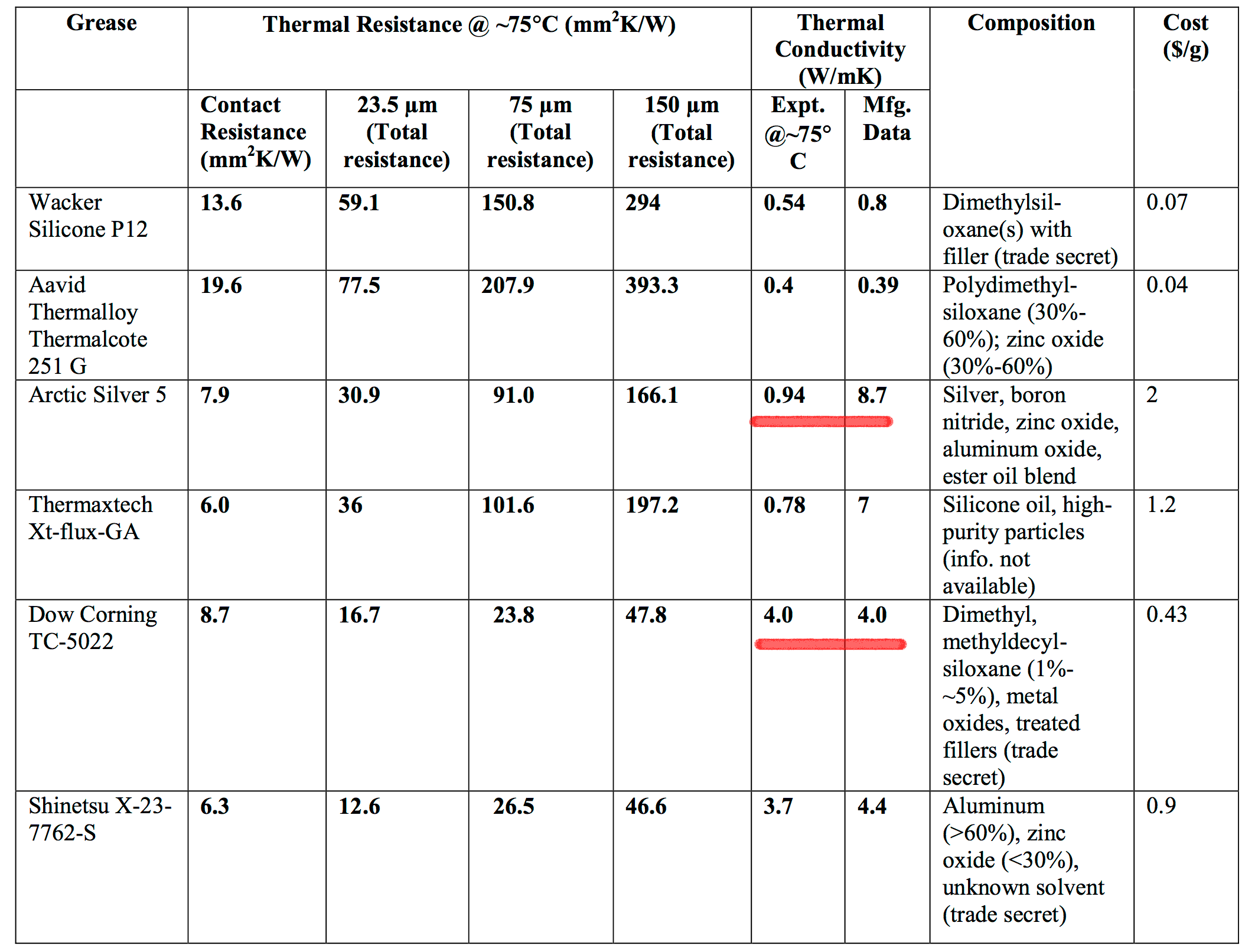

Arctic Silver 5's claimed thermal conductivity, according to the company: 8.7 W/(m·K).

The US National Renewable Energy Laboratory's study finding: 0.94 W/(m·K).

Narumanchi, Sreekant; Mihalic, Mark; Kelly, Kenneth; Eesley, Gary (2008). "Thermal interface materials for power electronics applications" (PDF). 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, 2008: ITHERM 2008: 28 - 31 May 2008. IEEE. Table 2. doi:10.1109/ITHERM.2008.4544297.

The Dow paste performed to its claimed specifications. Not only that, it's a much less expensive product with higher performance.

I would have thought the company would have released an Arctic Silver 6 to deal with this exposure but apparently not enough people in the enthusiast community know about it. Almost every time I read about paste someone mentions AS5 and it's still prevalent in stores. So, here is the apparent beef.

The US National Renewable Energy Laboratory's study finding: 0.94 W/(m·K).

Narumanchi, Sreekant; Mihalic, Mark; Kelly, Kenneth; Eesley, Gary (2008). "Thermal interface materials for power electronics applications" (PDF). 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, 2008: ITHERM 2008: 28 - 31 May 2008. IEEE. Table 2. doi:10.1109/ITHERM.2008.4544297.

The Dow paste performed to its claimed specifications. Not only that, it's a much less expensive product with higher performance.

I would have thought the company would have released an Arctic Silver 6 to deal with this exposure but apparently not enough people in the enthusiast community know about it. Almost every time I read about paste someone mentions AS5 and it's still prevalent in stores. So, here is the apparent beef.

They're like "Btech HM2 thermoplastic with embedded carbon fibers has a factor of 3 to 4 lower resistance than the best commercial greases." "From viewpoint of both performance and reliability, there is an industry trend towards bonded interface"

They're like "Btech HM2 thermoplastic with embedded carbon fibers has a factor of 3 to 4 lower resistance than the best commercial greases." "From viewpoint of both performance and reliability, there is an industry trend towards bonded interface"