Noctua Shows New Coolers and Fans at Computex 2024

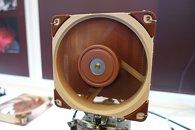

In addition to the thermosiphon liquid cooler project, Noctua also brought several upcoming air CPU coolers and fans to the Computex 2024 show, including the new NH-D15 G2, the NF-A14x25 G2, as well as next-generation dual-tower 120 mm CPU cooler and next-generation 120 mm fan.

The new NH-D15 G2 is the upgraded version of the popular NH-D15, which now gets a new fin stacks with reduced fin pitch, leaving it with 20 percent more surface area, 8 heatpipes (instead of 6 on the NH-D15), new fans with both higher performance and acoustic optimization, and offset design for better PCI clearance. It will use Noctua's Torx based SecuFirm2+ mounting system with offset option for AM5, as well as come bundled with NT-H2 thermal paste, NA-TPG1 thermal paste guard for AM5, and NA-ISW1 shim-washers for improved contact on LGA1700 sockets. Noctua will launch three different versions, the standard version with medium base convexity, as well as two new versions LBC and HBC, with low base and high base convexity. The new NH-D15 G2 should launch later this month.

The new NH-D15 G2 is the upgraded version of the popular NH-D15, which now gets a new fin stacks with reduced fin pitch, leaving it with 20 percent more surface area, 8 heatpipes (instead of 6 on the NH-D15), new fans with both higher performance and acoustic optimization, and offset design for better PCI clearance. It will use Noctua's Torx based SecuFirm2+ mounting system with offset option for AM5, as well as come bundled with NT-H2 thermal paste, NA-TPG1 thermal paste guard for AM5, and NA-ISW1 shim-washers for improved contact on LGA1700 sockets. Noctua will launch three different versions, the standard version with medium base convexity, as well as two new versions LBC and HBC, with low base and high base convexity. The new NH-D15 G2 should launch later this month.