0

0

Super Flower Leadex Platinum 1200 W Review

Efficiency, Temperatures & Noise »Test Setup

All measurements were performed using two Chroma 6314A mainframes equipped with the following electronic loads: six 63123A [350 W each], one 63102A [100 W x2], and one 63101A [200 W]. The aforementioned equipment is capable of delivering 2500 W of load, and all loads are controlled by a custom-made software. We also used a Rigol DS2072A oscilloscope kindly sponsored by Batronix, a Picoscope 3424 oscilloscope, a Picotech TC-08 thermocouple data logger, two Fluke multimeters (models 289 and 175), and a Yokogawa WT210 power meter. We also included a wooden box, which, along with some heating elements, was used as a hot box. Finally, we had at our disposal three more oscilloscopes (Rigol VS5042, Stingray DS1M12, and a second Picoscope 3424), and a CEM DT-8852 sound level meter. In this article, you will find more details about our equipment and the review methodology we follow. Finally, we conduct all of our tests at 40°C-45°C ambient to simulate the environment seen inside a typical system with a higher accuracy, with 40°C-45°C being derived from a standard ambient assumption of 23°C and 17°C-22°C being added for the typical temperature rise within a system.Primary Rails Voltage Regulation

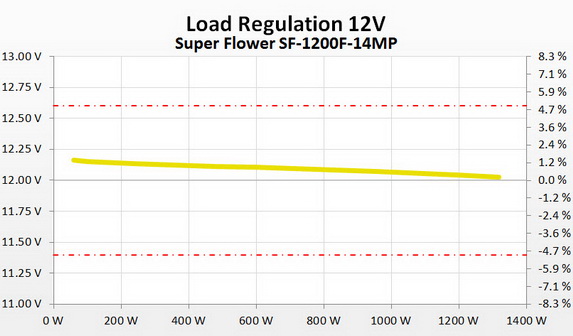

The following charts show the voltage values of the main rails, recorded over a range from 60 W to the maximum specified load, and the deviation (in percent) for the same load range.

5VSB Regulation

The following chart shows how the 5VSB rail deals with the load we throw at it.

Hold-up Time

Hold-up time is a very important PSU characteristic and represents the amount of time, usually measured in milliseconds, a PSU can maintain output regulations as defined by the ATX spec without input power. In other words, it is the amount of time the system can continue to run without shutting down or rebooting during a power interruption. The ATX specification sets the minimum hold-up time to 16 ms with the maximum continuous output load. In the following screenshot, the blue line is the mains signal and the yellow line is the "Power Good" signal. The latter is de-asserted to a low state when any of the +12V, 5V, or 3.3V output voltages fall below the undervoltage threshold, or after the mains power has been removed for a sufficiently long time to guarantee that the PSU cannot operate anymore.

Hold-up time unfortunately didn't reach 16 ms, so the unit failed this test. Units with such a high capacity struggle to achieve the minimum allowed time the ATX spec sets as there is only so much room on the main PCB for large bulk caps.

Inrush Current

Inrush current or switch-on surge refers to the maximum, instantaneous input-current drawn by an electrical device when it is first turned on. Because of the charging current of the APFC capacitor(s), PSUs produce large inrush-current right as they are turned on. Large inrush current can cause the tripping of circuit breakers and fuses and may also damage switches, relays, and bridge rectifiers; as a result, the lower the inrush current of a PSU right as it is turned on, the better.

While it didn't reach the required hold-up time, its bulk caps are still huge, so its inrush current was also pretty high.

Voltage Regulation and Efficiency Measurements

The first set of tests revealed the stability of the voltage rails and the efficiency of the Leadex-1200. The applied load was equal to (approximately) 20%, 40%, 50%, 60%, 80%, 100% and 110% of the maximum load that the PSU can handle.We conducted two additional tests. In the first test, we stressed the two minor rails (5V and 3.3V) with a high load while the load at +12V was only 0.10 A. This test reveals whether the PSU is Haswell ready or not. In the second test, we dialed the maximum load the +12V rail can handle while the load on the minor rails was minimal.

| Voltage Regulation & Efficiency Testing Data - Super Flower SF-1200F-14MP | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Test | 12 V | 5 V | 3.3 V | 5VSB | Power (DC/AC) | Efficiency | Fan Speed | Fan Noise | Temp (In/Out) | PF/AC Volts |

| 20% Load | 17.976A | 1.982A | 1.999A | 0.996A | 239.73W | 92.00% | 0 RPM | 0 dBA | 49.15°C | 0.957 |

| 12.137V | 5.028V | 3.299V | 5.003V | 260.57W | 36.99°C | 230.2V | ||||

| 40% Load | 36.365A | 3.981A | 4.006A | 1.201A | 479.61W | 93.34% | 1010 RPM | 37.8 dBA | 39.98°C | 0.984 |

| 12.113V | 5.020V | 3.293V | 4.984V | 513.85W | 45.20°C | 230.1V | ||||

| 50% Load | 45.440A | 4.976A | 5.014A | 1.610A | 599.53W | 93.25% | 1010 RPM | 37.8 dBA | 40.52°C | 0.987 |

| 12.107V | 5.017V | 3.290V | 4.967V | 642.95W | 46.13°C | 230.0V | ||||

| 60% Load | 54.546A | 5.982A | 6.024A | 2.019A | 719.45W | 93.11% | 1010 RPM | 37.8 dBA | 41.88°C | 0.990 |

| 12.095V | 5.013V | 3.286V | 4.948V | 772.70W | 47.97°C | 230.0V | ||||

| 80% Load | 72.989A | 7.988A | 8.051A | 2.435A | 959.25W | 92.32% | 1530 RPM | 46.5 dBA | 43.78°C | 0.991 |

| 12.069V | 5.005V | 3.279V | 4.923V | 1039.00W | 50.16°C | 229.9V | ||||

| 100% Load | 92.340A | 9.005A | 9.074A | 2.545A | 1199.16W | 91.50% | 1995 RPM | 53.2 dBA | 44.99°C | 0.991 |

| 12.043V | 4.999V | 3.273V | 4.905V | 1310.55W | 51.81°C | 229.8V | ||||

| 110% Load | 102.433A | 9.009A | 9.079A | 2.550A | 1319.12W | 91.02% | 1995 RPM | 53.2 dBA | 45.58°C | 0.991 |

| 12.027V | 4.994V | 3.270V | 4.899V | 1449.30W | 52.75°C | 229.7V | ||||

| Crossload 1 | 0.096A | 12.005A | 12.005A | 0.004A | 100.94W | 82.32% | 1530 RPM | 46.5 dBA | 44.07°C | 0.690 |

| 12.155V | 5.019V | 3.289V | 5.031V | 122.62W | 50.26°C | 230.6V | ||||

| Crossload 2 | 99.942A | 1.002A | 1.003A | 1.001A | 1215.97W | 91.86% | 1995 RPM | 53.2 dBA | 45.04°C | 0.991 |

| 12.035V | 5.005V | 3.285V | 4.957V | 1323.80W | 52.02°C | 229.8V | ||||

Feb 11th, 2025 23:27 EST

change timezone

Latest GPU Drivers

New Forum Posts

- Were Ryzen 8000 CPUs a big mistake from AMD? (8)

- It's happening again, melting 12v high pwr connectors (250)

- RTX5000 Series Owners Club (88)

- Do you guys have backup GPUs? (0)

- What are you playing? (22866)

- TECHPOWERUP HWBOT Contest Submissions List (66)

- Help me decide..........OLED monitors (28)

- 9800X3D OC Limits? (10)

- Do I need to spend extra money on my MOBO? (48)

- USB-C JBOD box (24)

Popular Reviews

- Civilization VII Performance Benchmark Review - 35 GPUs Tested

- Kingdom Come Deliverance II Performance Benchmark Review - 35 GPUs Tested

- Team Group T-Force XTREEM DDR5-7200 48GB CL34 Review

- ASRock Phantom Gaming B850I Lightning Wi-Fi Review

- DAREU A980 Pro Max Review

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

- NVIDIA GeForce RTX 5080 Founders Edition Review

- Corsair Frame 4000D Review

- Spider-Man 2 Performance Benchmark Review - 35 GPUs Tested

- MSI GeForce RTX 5080 Vanguard SOC Review

Controversial News Posts

- AMD Radeon 9070 XT Rumored to Outpace RTX 5070 Ti by Almost 15% (287)

- AMD is Taking Time with Radeon RX 9000 to Optimize Software and FSR 4 (256)

- AMD Denies Radeon RX 9070 XT $899 USD Starting Price Point Rumors (239)

- Edward Snowden Lashes Out at NVIDIA Over GeForce RTX 50 Pricing And Value (239)

- AMD Radeon RX 9070 XT & RX 9070 Custom Models In Stock at European Stores (226)

- New Leak Reveals NVIDIA RTX 5080 Is Slower Than RTX 4090 (215)

- AMD's Radeon RX 9070 Launch Faces Pricing Hurdles (175)

- AMD Radeon RX 9070 XT Tested in Cyberpunk 2077 and Black Myth: Wukong (169)