Sunday, January 22nd 2012

28 nm struggles: TSMC & GlobalFoundries

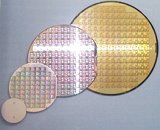

Making silicon chips is not easy, requiring hugely expensive fabs, with massive clean-room environments and at every process shrink, the complexity and difficulty of making the things goes up significantly. It looks like TSMC and GlobalFoundries are both having serious yield problems with their 28 nm process nodes, according to Mike Bryant, technology analyst at Future Horizons and this is causing a rash of non-working wafers - to the point of having nothing working with some chip designs submitted for production. It seems that the root cause of these problems are to do with the pressures of bringing products to market, rather than an inherent problem with the technology; it just takes time that they haven't got to iron out the kinks and they're getting stuck: "Foundries have come under pressure to release cell libraries too early - which end up with designs that don't work," Bryant said. In an effort to try and be seen to treat every customer equally, TSMC is attempting to launch ten 28 nm designs from seven companies, but it's not working out too well: "At 45-nm, only NVIDIA was affected. At 28-nm any problems for TSMC will be problems for many customers" said Bryant.GlobalFoundries are also struggling, although perhaps not quite as badly, according to Bryant: "However, there are recent comments of major yield problems with their 28-nm process actually being even worse than at GF [Globalfoundries]". Their 32 nm & 28 nm nodes are struggling, because they are using problematic gate first processing and this is worsened by the fact that they are using processes from two companies, AMD and IBM. Trying to debug two processes at once is causing serious headaches, compounded by a lack of cooperation between bases in Dresden and the US which appears to be caused by bad management.

Note that Bryant's assertions are at odds with what TSMC's CEO and chairman Morris Chang said when he spoke to analysts the previous day about the company's fourth quarter financial result: "Our 28-nm entered volume production last year and contributed 2 percent of 4Q11's wafer revenue. Defect density and new progress is ahead of schedule and is better than 40-45-nm at the corresponding stage of the ramp-up. We expect 28-nm ramp this year to be fast and we expect 28-nm will contribute more than 10 percent of total wafer revenue this year." It will soon become apparent who is right.

Regardkess, the pressure isn't going to let up for these companies, since Intel have been successfully manufacturing at the 32 nm level for a year, making their Sandy Bridge processors. On top of that, in April, Intel will introduce their significantly smaller 22 nm-based process technology in the form of their Ivy Bridge CPUs which have been demonstrated to work very well indeed. These are based on Intel's proprietary Tri-Gate 3D transistor technology too, which gives further performance increases, hence upping competitive pressures significantly.

Sources:

TG Daily, EE Times

Note that Bryant's assertions are at odds with what TSMC's CEO and chairman Morris Chang said when he spoke to analysts the previous day about the company's fourth quarter financial result: "Our 28-nm entered volume production last year and contributed 2 percent of 4Q11's wafer revenue. Defect density and new progress is ahead of schedule and is better than 40-45-nm at the corresponding stage of the ramp-up. We expect 28-nm ramp this year to be fast and we expect 28-nm will contribute more than 10 percent of total wafer revenue this year." It will soon become apparent who is right.

Regardkess, the pressure isn't going to let up for these companies, since Intel have been successfully manufacturing at the 32 nm level for a year, making their Sandy Bridge processors. On top of that, in April, Intel will introduce their significantly smaller 22 nm-based process technology in the form of their Ivy Bridge CPUs which have been demonstrated to work very well indeed. These are based on Intel's proprietary Tri-Gate 3D transistor technology too, which gives further performance increases, hence upping competitive pressures significantly.

33 Comments on 28 nm struggles: TSMC & GlobalFoundries

The only issue for GF is that volume production starts after Q2 2012(This has been known for sometime and some how the article makes it more grim than it sounds)

Anything to do with SWPA?

The advantage Intel has with the manufacturing process will probably give them an edge when entering on SoC market with Medfield while all the rest struggles with TMSC 28nm problems.There isn't the need to jump on 28nm graphics right now, assuming you are talking about graphics of course :), consoles are holding the development and until they get a refresh the "older" 5xx/6xxx series are more than enough for playing.

Looks like it is definitely a bunch of FUD.

Fab 1 - Dresden, Germany

Fab 8 - Luther Forest Technology Campus, Saratoga County, New York, USA

Are the only two that AMD use to have ownership on

www.globalfoundries.com/manufacturing/300mm.aspx

www.globalfoundries.com/manufacturing/200mm.aspx

Everything else was Chartered Semiconductor

www.globalfoundries.com/manufacturing/fab8_overview.aspx

Take note of this:If I had anything to speculate I would be saying GlobalFoundries is perfecting the process before going into volume rather than releasing the process in an unoptimized way

My guesses:

28nm-SHP => 28nm FD-SOI UTBOX HKMG eSiGe (Kaveri APU/Steamroller CPU)

28nm-HPP => 28nm Bulk HKMG eSiGe

28nm-HP => 28nm Bulk HKMG eSiGe

28nm-SLP => 28nm Bulk HKMG eSiGe

28nm-LPH => 28nm FD-SOI UTBOX HKMG eSiGe (Wichita/Krishna APUs(The current Bobcat is getting an extension on 40nm while these APUs are releasing next year))

Bold = Q2 2012 and later

Red Bold= Q4 2012 and later

You know Intel is sitting back laughing :rolleyes:

Once 28nm becomes full volume production it will mostly roll out

GF 28nm > TSMC 28nmI would actually wait and see Intel has been getting some backlash about lying about tidbits of their 22nm Tri-gate process

of all the chip players, Intel is one of the few that can actually relax for at least the entire Q1.

While Intel seem to be yanking out new process with less strain than TSMC or any other fab.

And there was an article here stating that Intel has 14nm chips already being tested in their labs as of last year, and its not due till 2014 i think, that's how Intel does it, If they are to release new nanometer they start preparing years in advance.

Development: 1st. Intel 2nd. Anyone part of the SOI Consortium(IBM, GlobalFoundries, STMicroelectrics, etc.

Production of the Highest End: 1. GlobalFoundries 2. Intel

GlobalFoundries 32nm-SHP should be the most expensive process yet it is cheaper than Intel's 32nm high-end process

There is no way 315.8mm² of 32nm-SHP actually costs $245- and 32nm from Intel at 200-295mm² costs $285+