Yangtze Memory Begins Mass-production of 64-layer 3D NAND Flash Memory

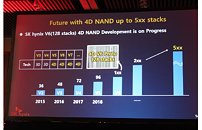

Yangtze Memory Technologies (YMTC), a Chinese state-backed semiconductor company founded in 2016 as part of the Chinese Government's tech-independence push, has commenced mass-production of 64-layer 3D NAND flash memory chips, at a rate of 100,000 to 150,000 wafers per month leading into 2020. The 64-layer 3D NAND chips are based on YMTC's "in-house" Xtracking architecture. The company is already developing a 128-layer 3D NAND flash chip, and is skipping 96-layer along the way.

YMTC's capacity will be augmented by a new fab being built by its parent company, Tsinghua Unigroup. Tsinghua is a state-owned company which holds a controlling 51 percent stake in YMTC, and is a beneficiary of China's National Semiconductor Industry Investment Fund. When it goes online in 2021-22, the new Tsinghua fab, located in Chengdu, will augment YMTC's capacity by an additional 100,000 12-inch wafers per month. Its existing fab in Nanjing will also receive a capacity expansion.

YMTC's capacity will be augmented by a new fab being built by its parent company, Tsinghua Unigroup. Tsinghua is a state-owned company which holds a controlling 51 percent stake in YMTC, and is a beneficiary of China's National Semiconductor Industry Investment Fund. When it goes online in 2021-22, the new Tsinghua fab, located in Chengdu, will augment YMTC's capacity by an additional 100,000 12-inch wafers per month. Its existing fab in Nanjing will also receive a capacity expansion.