qubit

Overclocked quantum bit

- Joined

- Dec 6, 2007

- Messages

- 17,865 (2.78/day)

- Location

- Quantum Well UK

| System Name | Quantumville™ |

|---|---|

| Processor | Intel Core i7-2700K @ 4GHz |

| Motherboard | Asus P8Z68-V PRO/GEN3 |

| Cooling | Noctua NH-D14 |

| Memory | 16GB (2 x 8GB Corsair Vengeance Black DDR3 PC3-12800 C9 1600MHz) |

| Video Card(s) | MSI RTX 2080 SUPER Gaming X Trio |

| Storage | Samsung 850 Pro 256GB | WD Black 4TB | WD Blue 6TB |

| Display(s) | ASUS ROG Strix XG27UQR (4K, 144Hz, G-SYNC compatible) | Asus MG28UQ (4K, 60Hz, FreeSync compatible) |

| Case | Cooler Master HAF 922 |

| Audio Device(s) | Creative Sound Blaster X-Fi Fatal1ty PCIe |

| Power Supply | Corsair AX1600i |

| Mouse | Microsoft Intellimouse Pro - Black Shadow |

| Keyboard | Yes |

| Software | Windows 10 Pro 64-bit |

Following our article yesterday about AMD using new high performance liquid cooling technology for their upcoming 7900-series graphic cards, TechPowerUp can now bring you a detailed insight into how this technology works, which has been developed by Vapro Inc. The following slides will help to explain this technology.

By using liquid cooling based heatsinks, the following performance advantages are achieved: improvement of thermal resistance, handling of high heat flux and power and easy to manufacture.

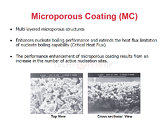

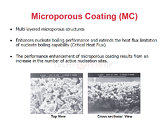

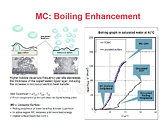

A microporous coating (MC) is applied to the hot side of the heatsink to help improve the heat carrying capacity of the boiling liquid, by significantly increasing the number of nucleation sites. "Nucleation sites" are surfaces that contact the liquid. Making the contact surface rough helps the water to form small bubbles sooner, allowing the boiling process to start more readily and be more vigorous.

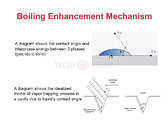

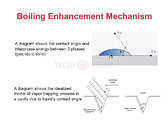

The diagrams below illustrate how the boiling enhancement mechanism works. The droplet size and manner in which it is trapped are important factors in enhancing boiling.

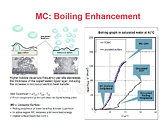

The following diagram illustrates how the microporous surface increases the number of bubbles produced, allowing more heat to be carried away more quickly, leading to much greater cooling efficiency. Notice how the thickness of the superheated layer is much reduced, as the liquid boils away sooner, thus preventing it from building up and trapping the heat against the hot component.

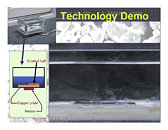

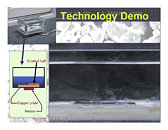

Here, the enhancement that the microporous coating makes is shown in a photograph of the device in action. The coating is on the right side and the liquid can be seen to be bubbling away on the right side, but not the left side. A video demo on YouTube is here.

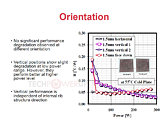

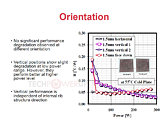

With a liquid-based cooler, one would expect its orientation to matter due to gravity and it does, but not by very much. In fact, mounting the cooler vertically actually improves performance at higher power levels, compared to the horizontal orientation. Note that the cooler works just as effectively face down for high power levels, where it matters most. Efficiency reduces somewhat at low power levels, but this doesn't really matter very much, as there isn't much heat to remove anyway.

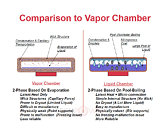

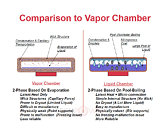

Next, we can see a comparison between the way current vapour chamber technology works and the new liquid chamber technology. The most common form of high performance cooling technology today for graphics cards, is vapour chamber cooling, where a small amount of liquid evaporates from the hot surface, is wicked up into the radiator where it cools and then condenses back into liquid, where the cycle starts again. On the other hand, liquid cooling uses a much greater amount of liquid, which actually boils. The resulting vapour then condenses back into liquid form against the radiator and goes back into the pool of liquid resting against the hot surface.

Potential issues with vapour chamber technology are the potential for it to dry out due to the small amount of liquid present, not very robust physically and difficult to make. Liquid chamber solves all these problems and more.

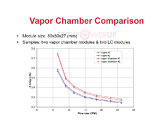

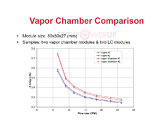

Here, we see a comparison of cooling effectiveness between two vapour chamber modules and two liquid cooling modules. Notice how the liquid modules do measurably better, especially at low flow rates, allowing the fan to rotate more slowly, therefore leading to a quieter cooler.

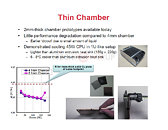

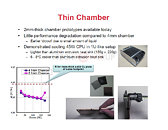

The chamber can be made just 2 mm thick and still achieve good cooling capacity, compared to a 4 mm thick one. As one can see, the 2 mm chamber is almost as effective as the 4 mm one, until around the 175W level, where the 4 mm chamber's performance starts to pull ahead.

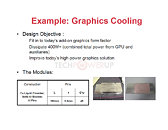

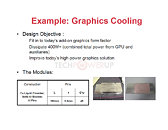

The design objective for liquid coolers is to be fitted onto very high powered graphics cards, where 400W+ is expected to be consumed between the GPU and its supporting circuitry, especially the power circuits. 400W+ is a level that previous technology would struggle to handle effectively.

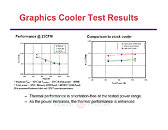

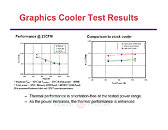

These test results show that the cooler's orientation makes no difference at the tested power range. Also, it's more effective than the stock 8800 GTX vapour chamber cooler that this has been compared against, especially where more power is being dissipated by the graphics card.

Below, is a quick summary of the benefits of this new technology, the most prominent being the efficient handling of large amounts of heat, making it suitable for the high powered graphics cards of the future and being relatively orientation free.

The company's website is at www.vaproinc.com

View at TechPowerUp Main Site

By using liquid cooling based heatsinks, the following performance advantages are achieved: improvement of thermal resistance, handling of high heat flux and power and easy to manufacture.

A microporous coating (MC) is applied to the hot side of the heatsink to help improve the heat carrying capacity of the boiling liquid, by significantly increasing the number of nucleation sites. "Nucleation sites" are surfaces that contact the liquid. Making the contact surface rough helps the water to form small bubbles sooner, allowing the boiling process to start more readily and be more vigorous.

The diagrams below illustrate how the boiling enhancement mechanism works. The droplet size and manner in which it is trapped are important factors in enhancing boiling.

The following diagram illustrates how the microporous surface increases the number of bubbles produced, allowing more heat to be carried away more quickly, leading to much greater cooling efficiency. Notice how the thickness of the superheated layer is much reduced, as the liquid boils away sooner, thus preventing it from building up and trapping the heat against the hot component.

Here, the enhancement that the microporous coating makes is shown in a photograph of the device in action. The coating is on the right side and the liquid can be seen to be bubbling away on the right side, but not the left side. A video demo on YouTube is here.

With a liquid-based cooler, one would expect its orientation to matter due to gravity and it does, but not by very much. In fact, mounting the cooler vertically actually improves performance at higher power levels, compared to the horizontal orientation. Note that the cooler works just as effectively face down for high power levels, where it matters most. Efficiency reduces somewhat at low power levels, but this doesn't really matter very much, as there isn't much heat to remove anyway.

Next, we can see a comparison between the way current vapour chamber technology works and the new liquid chamber technology. The most common form of high performance cooling technology today for graphics cards, is vapour chamber cooling, where a small amount of liquid evaporates from the hot surface, is wicked up into the radiator where it cools and then condenses back into liquid, where the cycle starts again. On the other hand, liquid cooling uses a much greater amount of liquid, which actually boils. The resulting vapour then condenses back into liquid form against the radiator and goes back into the pool of liquid resting against the hot surface.

Potential issues with vapour chamber technology are the potential for it to dry out due to the small amount of liquid present, not very robust physically and difficult to make. Liquid chamber solves all these problems and more.

Here, we see a comparison of cooling effectiveness between two vapour chamber modules and two liquid cooling modules. Notice how the liquid modules do measurably better, especially at low flow rates, allowing the fan to rotate more slowly, therefore leading to a quieter cooler.

The chamber can be made just 2 mm thick and still achieve good cooling capacity, compared to a 4 mm thick one. As one can see, the 2 mm chamber is almost as effective as the 4 mm one, until around the 175W level, where the 4 mm chamber's performance starts to pull ahead.

The design objective for liquid coolers is to be fitted onto very high powered graphics cards, where 400W+ is expected to be consumed between the GPU and its supporting circuitry, especially the power circuits. 400W+ is a level that previous technology would struggle to handle effectively.

These test results show that the cooler's orientation makes no difference at the tested power range. Also, it's more effective than the stock 8800 GTX vapour chamber cooler that this has been compared against, especially where more power is being dissipated by the graphics card.

Below, is a quick summary of the benefits of this new technology, the most prominent being the efficient handling of large amounts of heat, making it suitable for the high powered graphics cards of the future and being relatively orientation free.

The company's website is at www.vaproinc.com

View at TechPowerUp Main Site

Last edited:

- very obvious now but I wouldn't have come up with anything like that so it does seem good to me - I want to see comparisons though on actual cooling comparisons at different angles done with multiple units of both types at different loads though lol.

- very obvious now but I wouldn't have come up with anything like that so it does seem good to me - I want to see comparisons though on actual cooling comparisons at different angles done with multiple units of both types at different loads though lol.