- Joined

- Aug 16, 2005

- Messages

- 26,860 (3.82/day)

- Location

- Alabama

| System Name | RogueOne |

|---|---|

| Processor | Xeon W9-3495x |

| Motherboard | ASUS w790E Sage SE |

| Cooling | SilverStone XE360-4677 |

| Memory | 128gb Gskill Zeta R5 DDR5 RDIMMs |

| Video Card(s) | MSI SUPRIM Liquid X 4090 |

| Storage | 1x 2TB WD SN850X | 2x 8TB GAMMIX S70 |

| Display(s) | 49" Philips Evnia OLED (49M2C8900) |

| Case | Thermaltake Core P3 Pro Snow |

| Audio Device(s) | Moondrop S8's on schitt Gunnr |

| Power Supply | Seasonic Prime TX-1600 |

| Mouse | Lamzu Atlantis mini (White) |

| Keyboard | Monsgeek M3 Lavender, Moondrop Luna lights |

| VR HMD | Quest 3 |

| Software | Windows 11 Pro Workstation |

| Benchmark Scores | I dont have time for that. |

Thanks to @Xx Tek Tip xX a few months ago for pointing me in the right direction. (I was originally going to do bare die but was advised instead to just to an IHS delid.

Its been a bit but finally got around to it.

Ambient Temp: 22ºC

CPU Clock: 4.5ghz all cores

Test: Intel XTU 15min stress test

CoreV: 1.250v

VCCIN: 2.1v

CPURingV: 1.3v

Machine went through 5min Intel XTU stress test to bring water and cpu temps up. Machine was then allowed to sit for 5min before starting 15min Intel XTU stress test.

Before Delid (Sustained Temps)

Max Temp: 90ºC

AVG Temp: 72ºC

Min Temp: 57ºC

To begin I needed to collect a few materials. First, I already had some conductonaut , Next I wanted to put some di-electric coating on the primary PCB substrate so that if the LM flowed or leaked I minimized my risk of toasting my chip. Next I wanted to make sure if I did mess up I could peel it off easily and that it would stick if I bonded it. The answer to that is gasket maker, worked for my valve cover, should work for an IHS. Lastly was heat.

Thankfully my CRC dielectric coat and gasket maker can take alot of heat so I was set. Finally I needed a delid kit. The fancy one was expensive and out of stock unless I wanted it shipped over the pond. Didnt really want to spend $100USD and didnt want to wait weeks. So I would up with a rockit 99 kit.

Thermal Grizzly

Rockit 99 x299 Delid Kit

Black RTV Gasket Maker

CRC dielectric waterproofer

Now lets get down to business. Here is the lineup of the tools we will be using.

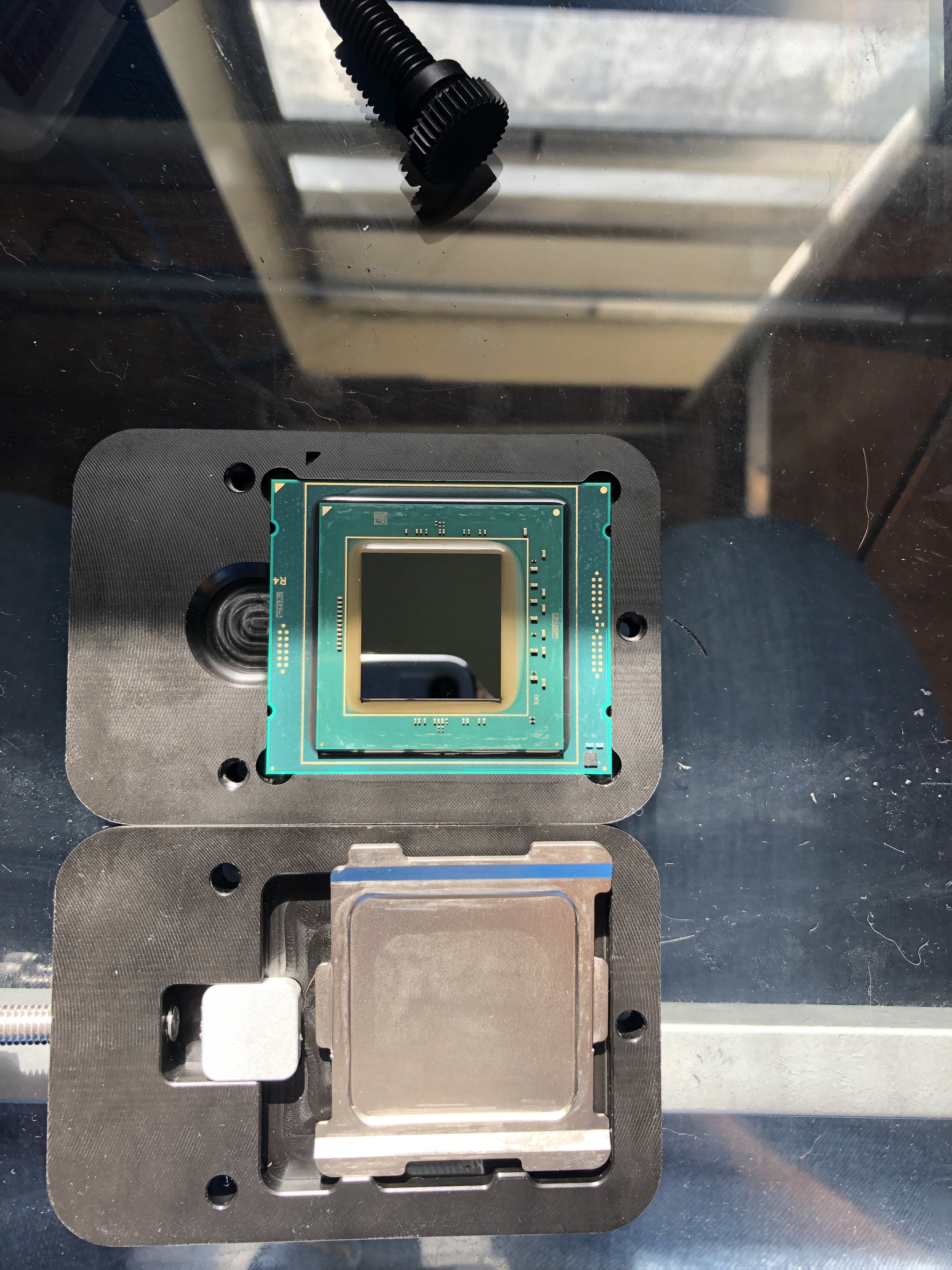

Candid shot of my 7980xe in the delid tool getting ready for IHS removal

My Rickit99 Kit did not come with all of the needed thumb screws. Thankfully the manual turn down screws worked with the threading, though admittedly it did seem a little different. I honestly reccomend or rather, I pre-heated my CPU for around a min on max heat from my wifes hair dryer. Then I put the top on. I did this to minimize risk of the bonding agent cracking my substrate. I have never personally worked with the material so I was uncertain how easy it would be to give. This was just a safety measure. It should be noted that many have done this and not applied heat before hand.

Well we are separated now. No going back! It was easy but I was nervous the entire time. You have no idea if you have damaged it except physically. Until you are done. The clear takes 15min to dry to non-tack. The RTV takes an hour. so that 1:15min in just prep and ready time. The rest is fantastic manual labor. If you do not routinely physically "write" for a long period of time your hand is going to hurt.

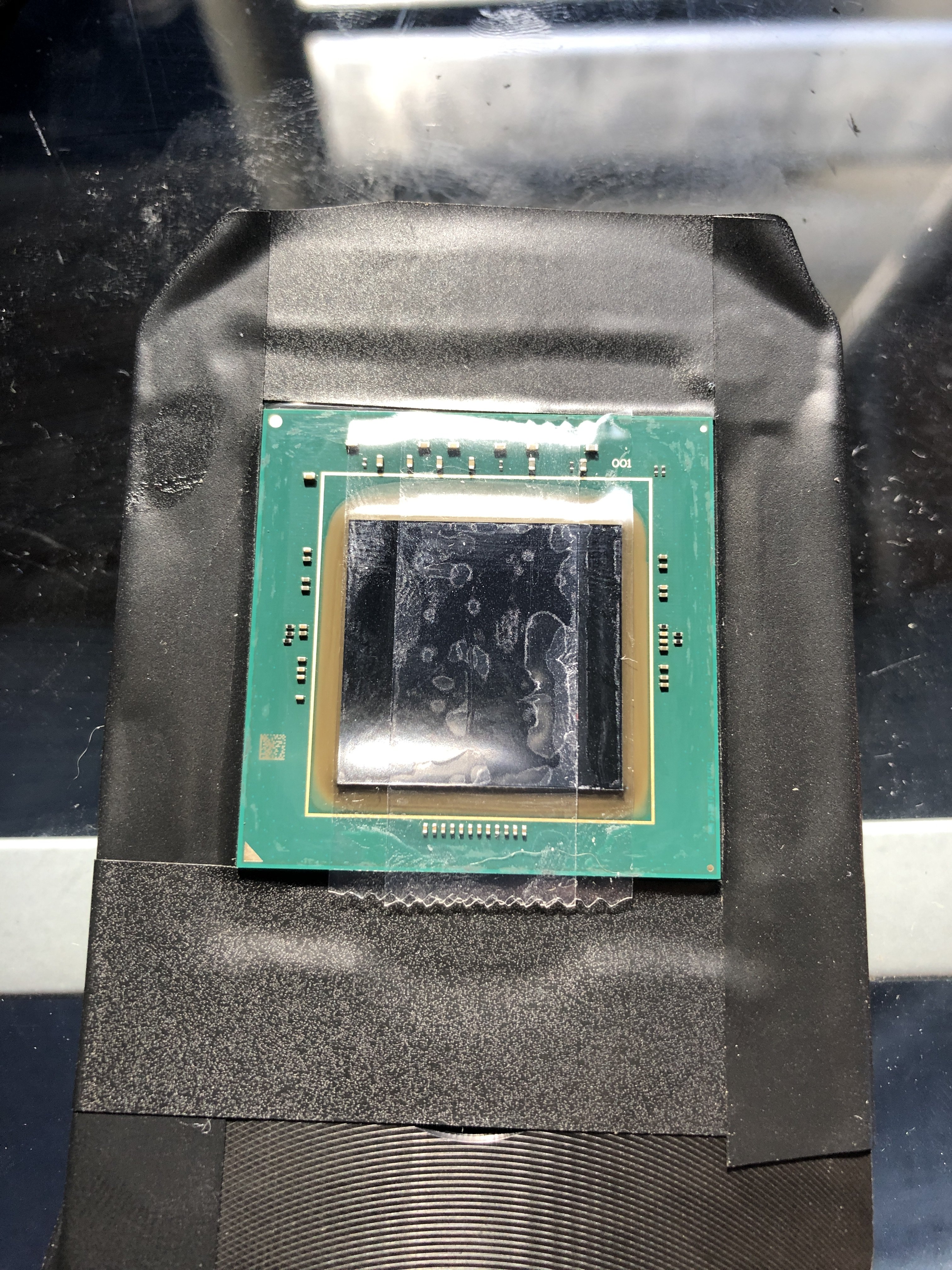

Here we are right after IHS removal, prior to cleaning

The delid kit comes with a bamboo pick of sorts with a sharp tip and a sharp wide end. The substance that keeps the IHS on by stock is very similar to RTV but less rubbery. I would hazard at how very easy it was to "rub off" that it is silicon based, the compound is a bit sturdy however. In either case "scraping" the adhesive like substance off was time consuming bu not in itself difficult. The adhesive came off relatively easy with a little pressure on the tip part of the bamboo pick. The widepart came in handy for cleaning the inner corners of adhesive. If you are experienced or know how to use a chisel you already understand what I mean. It's hard to describe.

Below I have completed the initial scraping of the CPU PCB and I work on the IHS last.

After the scraping is done, I use 91% isopropyl to clean the rest of the adhesive off. The layers remaining at this point are so thin it is pretty effortless. It should be noted I had some microfiber lint free towels from Amazon, I used to "polish" the die and PCB after I was done, to get rid of residue and clean the qtip lint from the surfaces.

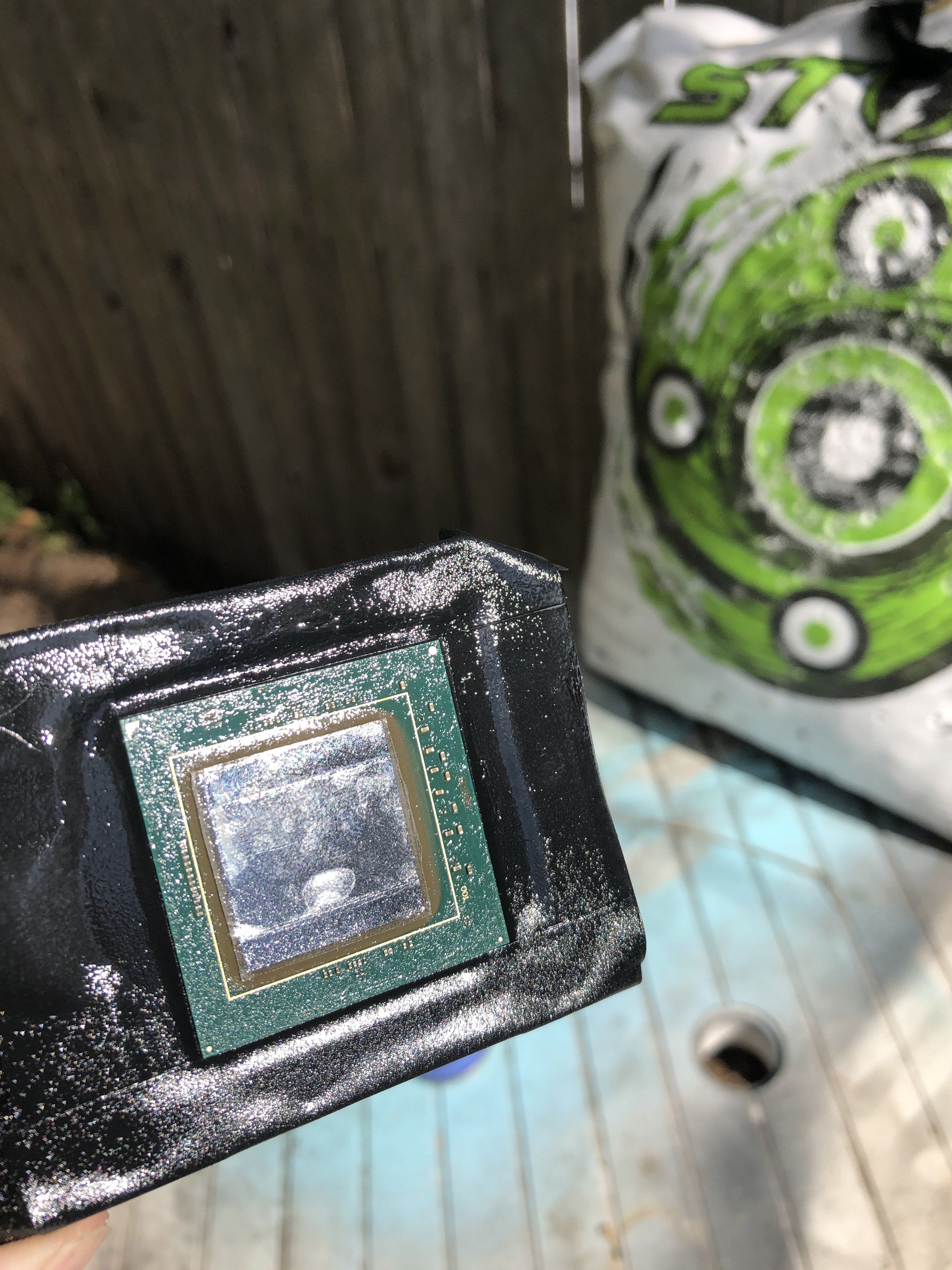

Now time to tape off the die and the secondary PCB. This is done to protect them from the urethane coating. I use normal electrical tape on secondary PCB and scotch tape on the die. I do this because scotch tape leaves less adhesive behind, wheras electrical is very tacky and leaves a heavy residue. I wanted to cut as much cleaning time in the final product as possible to minimize risk of removing the coating with solvents. I cover the secondary PCB because it is lower than the primary PCB and thus lower than the core. Because of this if the LM flows and drips it will drip onto a GPU or another part of the machine since it will be vertical.

I also coat the primary PCB step in general because that is where the majority of the contacts are. Finally, I dont do the secondary PCB as a whole because a little run on incase of a tape seal issue to the secondary PCB would not be a problem. However if I sprayed the secondary PCB and some ran under or hung off of the bottom of the CPU and pin array I would have a difficult time removing it.

12-15" from the CPU go ahead and put on a nice even light coat. I reccomend trying on something else to get used to your nozzle flow. In reality I dont need to teach you how to use aresol sprays, just try not to fuck this part up.

Now we have coated it. the Caps and contacts are covered and hopefully the tape holds. We let this bake in the sun on a table for 15-30min 15min you are fine but I had guests so I let it sit for 30. At which point it was not tacky or soft.

After drying its time to look it over for imperfections to determine if it needs a re-spray. Looks fine to me.

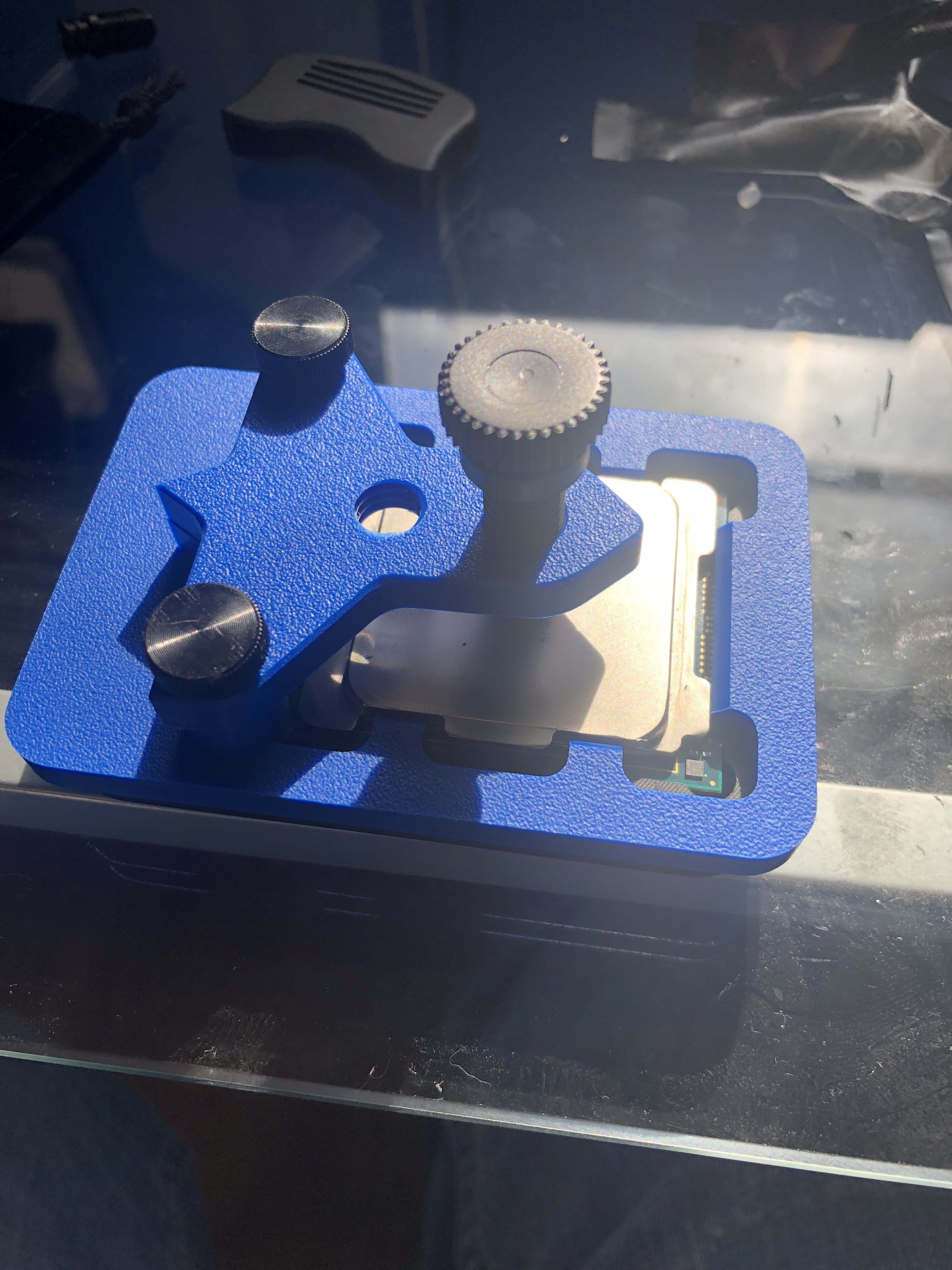

Now lets untape it and prepare the IHS for re-bond and LM application. You can see I am in the middle of it below.

Apply the LM to both sides and try to cover as much surface area as is applicable to your die size.

You can't see it in any pics because I didnt take them. But I referanced the IHS orientation VS the golden arrow on the CPU. This helped me make sure the orientation was correct for the IHS re-application. To do this I cut just the very tip of my RTV applicator off so I could produce a thin bead. I then only beaded the 4 wide primary inner IHS corners. This will seal it enough to allow for easy future removal. RTV gasket maker also isnt mega strong like super glue. their is no risk of ripping PCB layers off when you need to re-work.

Time to let it set

Now that we are all together. I applied LM to the water block and top of the IHS. This means I have LM between IHS and block and IHS and raw die. besides lapping, this is as good as its going to get.

Test results after are as follows. Using the same ambient and thermal staging done prior

After Delid (Sustained Temps)

Max Temp: 77ºC

AVG Temp: 62ºC

Min Temp: 49ºC

Differences before and after

Max Temp: 13ºC

AVG Temp: 10ºC

Min Temp: 8ºC

Overall I am super pleased! What a great drop in temps!

Its been a bit but finally got around to it.

Ambient Temp: 22ºC

CPU Clock: 4.5ghz all cores

Test: Intel XTU 15min stress test

CoreV: 1.250v

VCCIN: 2.1v

CPURingV: 1.3v

Machine went through 5min Intel XTU stress test to bring water and cpu temps up. Machine was then allowed to sit for 5min before starting 15min Intel XTU stress test.

Before Delid (Sustained Temps)

Max Temp: 90ºC

AVG Temp: 72ºC

Min Temp: 57ºC

To begin I needed to collect a few materials. First, I already had some conductonaut , Next I wanted to put some di-electric coating on the primary PCB substrate so that if the LM flowed or leaked I minimized my risk of toasting my chip. Next I wanted to make sure if I did mess up I could peel it off easily and that it would stick if I bonded it. The answer to that is gasket maker, worked for my valve cover, should work for an IHS. Lastly was heat.

Thankfully my CRC dielectric coat and gasket maker can take alot of heat so I was set. Finally I needed a delid kit. The fancy one was expensive and out of stock unless I wanted it shipped over the pond. Didnt really want to spend $100USD and didnt want to wait weeks. So I would up with a rockit 99 kit.

Thermal Grizzly

Rockit 99 x299 Delid Kit

Black RTV Gasket Maker

CRC dielectric waterproofer

Now lets get down to business. Here is the lineup of the tools we will be using.

Candid shot of my 7980xe in the delid tool getting ready for IHS removal

My Rickit99 Kit did not come with all of the needed thumb screws. Thankfully the manual turn down screws worked with the threading, though admittedly it did seem a little different. I honestly reccomend or rather, I pre-heated my CPU for around a min on max heat from my wifes hair dryer. Then I put the top on. I did this to minimize risk of the bonding agent cracking my substrate. I have never personally worked with the material so I was uncertain how easy it would be to give. This was just a safety measure. It should be noted that many have done this and not applied heat before hand.

Well we are separated now. No going back! It was easy but I was nervous the entire time. You have no idea if you have damaged it except physically. Until you are done. The clear takes 15min to dry to non-tack. The RTV takes an hour. so that 1:15min in just prep and ready time. The rest is fantastic manual labor. If you do not routinely physically "write" for a long period of time your hand is going to hurt.

Here we are right after IHS removal, prior to cleaning

The delid kit comes with a bamboo pick of sorts with a sharp tip and a sharp wide end. The substance that keeps the IHS on by stock is very similar to RTV but less rubbery. I would hazard at how very easy it was to "rub off" that it is silicon based, the compound is a bit sturdy however. In either case "scraping" the adhesive like substance off was time consuming bu not in itself difficult. The adhesive came off relatively easy with a little pressure on the tip part of the bamboo pick. The widepart came in handy for cleaning the inner corners of adhesive. If you are experienced or know how to use a chisel you already understand what I mean. It's hard to describe.

Below I have completed the initial scraping of the CPU PCB and I work on the IHS last.

After the scraping is done, I use 91% isopropyl to clean the rest of the adhesive off. The layers remaining at this point are so thin it is pretty effortless. It should be noted I had some microfiber lint free towels from Amazon, I used to "polish" the die and PCB after I was done, to get rid of residue and clean the qtip lint from the surfaces.

Now time to tape off the die and the secondary PCB. This is done to protect them from the urethane coating. I use normal electrical tape on secondary PCB and scotch tape on the die. I do this because scotch tape leaves less adhesive behind, wheras electrical is very tacky and leaves a heavy residue. I wanted to cut as much cleaning time in the final product as possible to minimize risk of removing the coating with solvents. I cover the secondary PCB because it is lower than the primary PCB and thus lower than the core. Because of this if the LM flows and drips it will drip onto a GPU or another part of the machine since it will be vertical.

I also coat the primary PCB step in general because that is where the majority of the contacts are. Finally, I dont do the secondary PCB as a whole because a little run on incase of a tape seal issue to the secondary PCB would not be a problem. However if I sprayed the secondary PCB and some ran under or hung off of the bottom of the CPU and pin array I would have a difficult time removing it.

12-15" from the CPU go ahead and put on a nice even light coat. I reccomend trying on something else to get used to your nozzle flow. In reality I dont need to teach you how to use aresol sprays, just try not to fuck this part up.

Now we have coated it. the Caps and contacts are covered and hopefully the tape holds. We let this bake in the sun on a table for 15-30min 15min you are fine but I had guests so I let it sit for 30. At which point it was not tacky or soft.

After drying its time to look it over for imperfections to determine if it needs a re-spray. Looks fine to me.

Now lets untape it and prepare the IHS for re-bond and LM application. You can see I am in the middle of it below.

Apply the LM to both sides and try to cover as much surface area as is applicable to your die size.

You can't see it in any pics because I didnt take them. But I referanced the IHS orientation VS the golden arrow on the CPU. This helped me make sure the orientation was correct for the IHS re-application. To do this I cut just the very tip of my RTV applicator off so I could produce a thin bead. I then only beaded the 4 wide primary inner IHS corners. This will seal it enough to allow for easy future removal. RTV gasket maker also isnt mega strong like super glue. their is no risk of ripping PCB layers off when you need to re-work.

Time to let it set

Now that we are all together. I applied LM to the water block and top of the IHS. This means I have LM between IHS and block and IHS and raw die. besides lapping, this is as good as its going to get.

Test results after are as follows. Using the same ambient and thermal staging done prior

After Delid (Sustained Temps)

Max Temp: 77ºC

AVG Temp: 62ºC

Min Temp: 49ºC

Differences before and after

Max Temp: 13ºC

AVG Temp: 10ºC

Min Temp: 8ºC

Overall I am super pleased! What a great drop in temps!

Last edited: