LOL. Board swappers kill me.

To the OP:

This is similar to the circuit you're looking at,at least at the driver side of it:

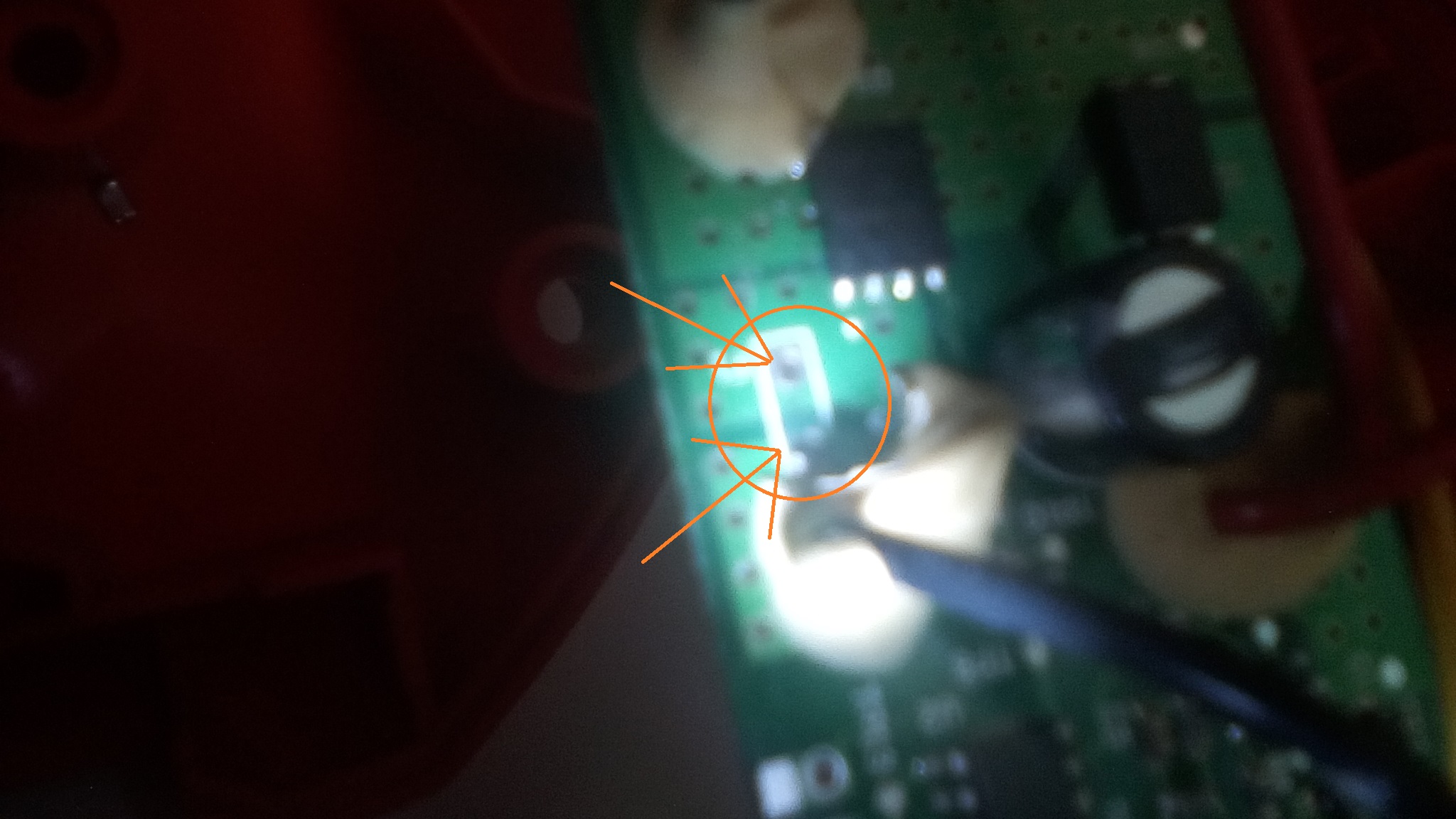

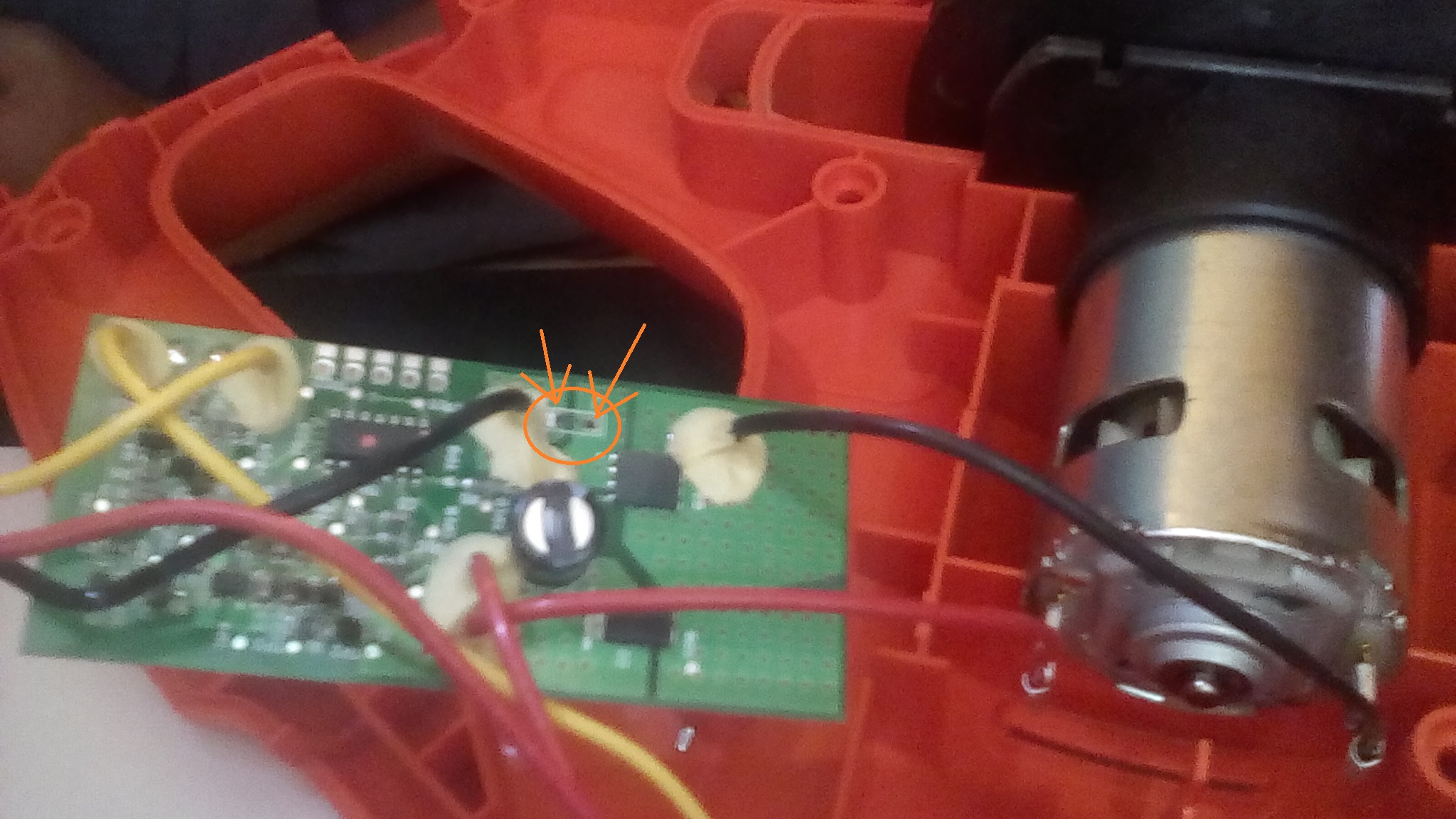

The 8-pin chip you see is Q1, the black component I identified is D2, and the missing part is the current limit, R10. Your motor is where this one says "hydrogen cell."

This is called a "Single Ended PWM Driver".

The rest of the control circuitry this shows is in the big chip at the center of your pic. It may be a TL494 or a newer variant; those are in everything.

It also uses the other transistors there; yours is also a Li-ion charger, so some of the circuitry on your board does that.

The PCB itself is no longer available, and there's no drawings available; The whole blower is available for $40 online, so taking it somewhere to get it fixed is going to be too expensive.

I'd solder a small piece of wire across the terminals where the resistor was; the resistor is going to be a very low value.

The one in the drawing above is 0.003 ohms, that's a larger piece of wire than I'm talking about using above.

Start small, if it unsolders itself at mid or full speed only, then use two pieces of wire, and keep going up until it quits doing that and glowing red.

If the transistor chip is bad, The added wire will glow red hot and unsolder itself instantly, like the original part did; the blackened part is where the thin, last piece of solder vaporized due to the current going thru it as is came off the board.

I've designed and repaired this kind of stuff for over 30 years; it's not hard to fix, if you can recognize the circuitry.

If you want, read and post the numbers off the transistor, diode, and control chip, and I'll see what I can find out for you.

A well focused pic, where I can read them is even better.

Search for the missing part; It's there somewhere.

These kinds of things start to fail, then we smack them, and the molten solder allows the part to fall off.

Modern SMT parts are on an alumina substrate, and resistors this small in value are metal films, so they get really hot, and melt the solder.

If you find it in one piece, you might be able to solder it back on.

You are likely to find the bearings are tight, if so, clean and lube them; check for hair wrapped around the shaft, or anything else that binds up the motor.

The harder the motor has to work, the hotter the circuit runs.

The only cooling is where the copper areas of that board are plated with copper; see all the holes? Those are called "Thermal Vias" and tie the fron of the board to the big copper area on the back of the board.

2" square will dissipate ~2 watts of power, in a limited area like that, if the air blows across it too.

The part that failed is the part designed to fail; it's a nice design.

Dewalt makes B&D; a buddy worked there doing failure prediction analysis.

Do you have a voltmeter, and know how to check a diode?

Take the battery out, and check the main parts.

Measure across the 8 pin chip, from the ganged leads on one side, to the 3 ganged leads on the other side; one way should be open, the other way should measure like a diode. (0.6v)

Measure the diode, same thing, one way open, other way ~0.6V.

If either are shorted both ways, there's the main problem.

The numbers will tell you what to buy; Digikey or Mouser will have parts that will work.

Good luck with it.