Raevenlord

News Editor

- Joined

- Aug 12, 2016

- Messages

- 3,755 (1.24/day)

- Location

- Portugal

| System Name | The Ryzening |

|---|---|

| Processor | AMD Ryzen 9 5900X |

| Motherboard | MSI X570 MAG TOMAHAWK |

| Cooling | Lian Li Galahad 360mm AIO |

| Memory | 32 GB G.Skill Trident Z F4-3733 (4x 8 GB) |

| Video Card(s) | Gigabyte RTX 3070 Ti |

| Storage | Boot: Transcend MTE220S 2TB, Kintson A2000 1TB, Seagate Firewolf Pro 14 TB |

| Display(s) | Acer Nitro VG270UP (1440p 144 Hz IPS) |

| Case | Lian Li O11DX Dynamic White |

| Audio Device(s) | iFi Audio Zen DAC |

| Power Supply | Seasonic Focus+ 750 W |

| Mouse | Cooler Master Masterkeys Lite L |

| Keyboard | Cooler Master Masterkeys Lite L |

| Software | Windows 10 x64 |

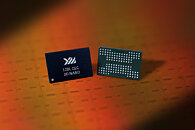

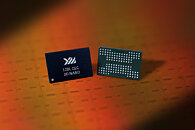

China's plans for world domination include the country slowly retracting itself from its dependency on western companies' technologies, via heavy acceleration of plans for and production of a myriad of semiconductor technologies. One of the more important technologies amongst those due to its relative ease of manufacture and overall market value is, of course, NAND technology. And the days of China being undoubtedly behind other manufacturers' technologies seems to be coming to an end, with the countries' Yangtze Memory Technologies (YMTC) 64-layer Xtacking TLC NAND design already achieving pretty impressive results compared to its mainstream counterparts.

Xtacking technology is expected to disrupt the $52 billion NAND memory market and its big players such as Micron, Samsung, SK Hynix, Kioxia, Western Digital, and Intel. The technology separates periphery circuits and memory cell operations towards a separate wafer, which allows for increased performance and throughput compared to other designs. Senior technical fellow Jeongdong Choe at Ottawa, Canada-based TechInsights (a company specializing in reverse-engineering semiconductor technology) has told EE Times YMTC's 64-layer, 256 Gb die bit density is 4.41 Gb/mm, which is higher than the Samsung equivalent 256 Gb die at 3.42 Gb/mm.

While other companies have been introducing ever-increasing layer-dense NAND designs (such as 96-layer and 128-layer designs from SK Hynix), the 64-layer design may seem retrograde; however, the company already has a working 128-bit QLC design, and will be scaling its TLC Xtacking NAND towards 128-layer 512 Gb chips, thus increasing its leverage against other companies' solutions.

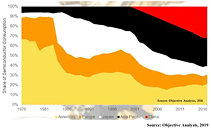

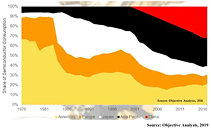

Funded in 2015, YMTC is an important part of China's "Made in china 2025" technology migration plan. When YMTC started operations, less than 20% of the chips consumed in China in 2015 were domestically produced. It seems YMTC may well be on the way to make the "Made in China 2025" plans to reach 40% domestic production by 2020 - and 70% by 2025.

View at TechPowerUp Main Site | Source

Xtacking technology is expected to disrupt the $52 billion NAND memory market and its big players such as Micron, Samsung, SK Hynix, Kioxia, Western Digital, and Intel. The technology separates periphery circuits and memory cell operations towards a separate wafer, which allows for increased performance and throughput compared to other designs. Senior technical fellow Jeongdong Choe at Ottawa, Canada-based TechInsights (a company specializing in reverse-engineering semiconductor technology) has told EE Times YMTC's 64-layer, 256 Gb die bit density is 4.41 Gb/mm, which is higher than the Samsung equivalent 256 Gb die at 3.42 Gb/mm.

While other companies have been introducing ever-increasing layer-dense NAND designs (such as 96-layer and 128-layer designs from SK Hynix), the 64-layer design may seem retrograde; however, the company already has a working 128-bit QLC design, and will be scaling its TLC Xtacking NAND towards 128-layer 512 Gb chips, thus increasing its leverage against other companies' solutions.

Funded in 2015, YMTC is an important part of China's "Made in china 2025" technology migration plan. When YMTC started operations, less than 20% of the chips consumed in China in 2015 were domestically produced. It seems YMTC may well be on the way to make the "Made in China 2025" plans to reach 40% domestic production by 2020 - and 70% by 2025.

View at TechPowerUp Main Site | Source