- Joined

- May 30, 2018

- Messages

- 1,890 (0.79/day)

- Location

- Cusp Of Mania, FL

| Processor | Ryzen 9 3900X |

|---|---|

| Motherboard | Asus ROG Strix X370-F |

| Cooling | Dark Rock 4, 3x Corsair ML140 front intake, 1x rear exhaust |

| Memory | 2x8GB TridentZ RGB [3600Mhz CL16] |

| Video Card(s) | EVGA 3060ti FTW3 Ultra Gaming |

| Storage | 970 EVO 500GB nvme, 860 EVO 250GB SATA, Seagate Barracuda 1TB + 4TB HDDs |

| Display(s) | 27" MSI G27C4 FHD 165hz |

| Case | NZXT H710 |

| Audio Device(s) | Modi Multibit, Vali 2, Shortest Way 51+ - LSR 305's, Focal Clear, HD6xx, HE5xx, LCD-2 Classic |

| Power Supply | Corsair RM650x v2 |

| Mouse | iunno whatever cheap crap logitech *clutches Xbox 360 controller security blanket* |

| Keyboard | HyperX Alloy Pro |

| Software | Windows 10 Pro |

| Benchmark Scores | ask your mother |

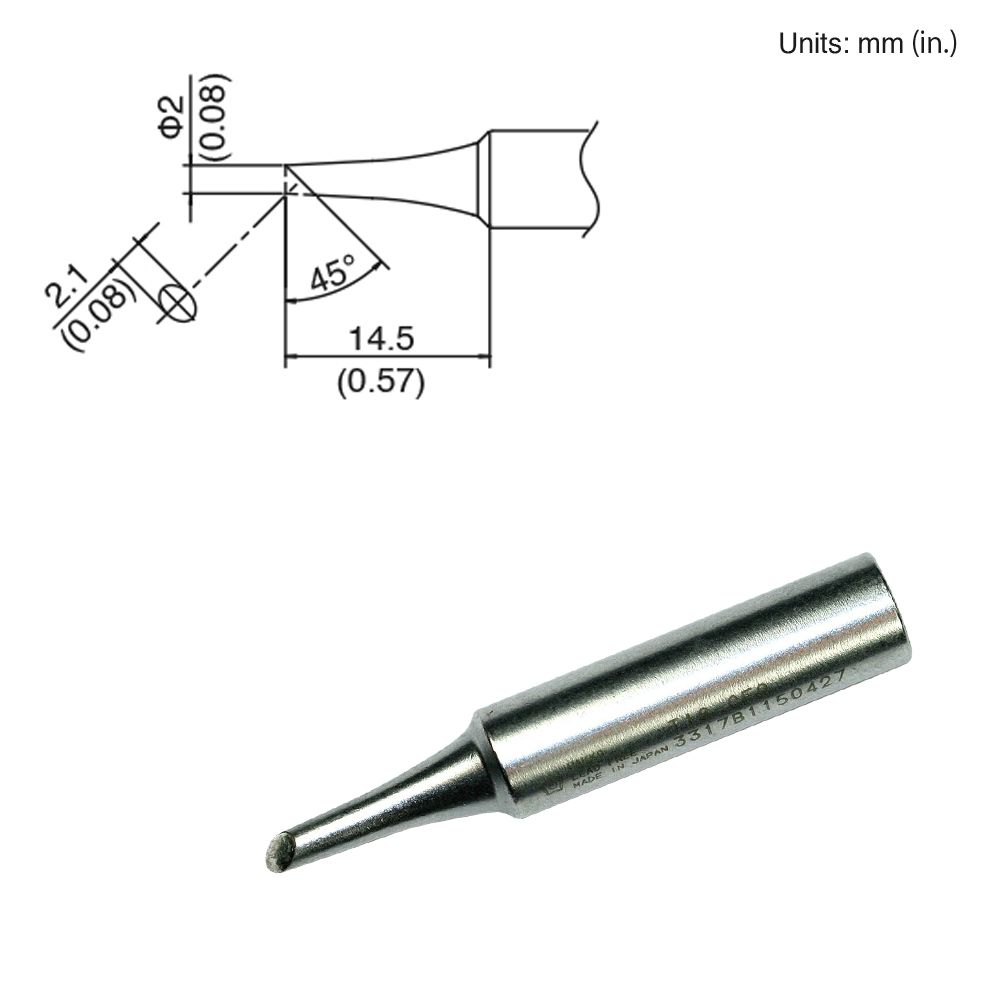

Nothing too exciting, but I finally got a new T18-CF2 bevel-cut tip for my trusty Hakko FX-888D.

Back in the day, a similar Hakko iron to the model I now have made me realize I don't in fact suck at soldering, I just had a sucky iron. These tips are indispensable for me, in a couple of sizes. Online, I see lots of people use the reservoir tips to do surface mount chips with lots of smaller leads but I originally learned to do it with a tip like this. I think the res is kind of a messy waste of solder, and this tip shape leaves you with much more consistently good joints with less solder. Fewer fused joints. You basically just want the angle right as you run horizontally across the pins. The pressure induced consistently gives you a close joint with even solder under, around, and over each pin - it all gets pushed right where it needs to go in just the right amounts. You've got a lot of heating surface so everything is getting to temperature, whereas the res spreads a lot of its heat through the solder it is keeping melted in the 'crater' of the tip. I also like this shape for soldering small wires to larger contacts, such as with instruments and headphone cables, where the extra surface area makes it quicker - and it still has a similar edge to a chisel tip for 'butting'. Sometimes when you are working on say, an amplifier, there are wires, surface-mount chips, and through hole. A tip like this can handle all of that without needing to swap or adjust temperature. That relatively large, flat surface combined with a pivot-able edge makes for a versatile tip. You can reduce heat flow by the angle you choose for the tip. This one is too big for smaller rectangular components. I can use a smaller T18-CF15 with steeper bevel angle and smaller diameter, which I already have a couple of, though that may be the one thing I swap to a chisel for.

Tips matter, man. Probably still more than I'm giving them credit for. And some people might actually smack me for this *shrug*

Back in the day, a similar Hakko iron to the model I now have made me realize I don't in fact suck at soldering, I just had a sucky iron. These tips are indispensable for me, in a couple of sizes. Online, I see lots of people use the reservoir tips to do surface mount chips with lots of smaller leads but I originally learned to do it with a tip like this. I think the res is kind of a messy waste of solder, and this tip shape leaves you with much more consistently good joints with less solder. Fewer fused joints. You basically just want the angle right as you run horizontally across the pins. The pressure induced consistently gives you a close joint with even solder under, around, and over each pin - it all gets pushed right where it needs to go in just the right amounts. You've got a lot of heating surface so everything is getting to temperature, whereas the res spreads a lot of its heat through the solder it is keeping melted in the 'crater' of the tip. I also like this shape for soldering small wires to larger contacts, such as with instruments and headphone cables, where the extra surface area makes it quicker - and it still has a similar edge to a chisel tip for 'butting'. Sometimes when you are working on say, an amplifier, there are wires, surface-mount chips, and through hole. A tip like this can handle all of that without needing to swap or adjust temperature. That relatively large, flat surface combined with a pivot-able edge makes for a versatile tip. You can reduce heat flow by the angle you choose for the tip. This one is too big for smaller rectangular components. I can use a smaller T18-CF15 with steeper bevel angle and smaller diameter, which I already have a couple of, though that may be the one thing I swap to a chisel for.

Tips matter, man. Probably still more than I'm giving them credit for. And some people might actually smack me for this *shrug*

Last edited:

They've also added Bluetooth and a remote now and ditched the control pod that used to be a point of problems/failure.

They've also added Bluetooth and a remote now and ditched the control pod that used to be a point of problems/failure.