Raevenlord

News Editor

- Joined

- Aug 12, 2016

- Messages

- 3,755 (1.19/day)

- Location

- Portugal

| System Name | The Ryzening |

|---|---|

| Processor | AMD Ryzen 9 5900X |

| Motherboard | MSI X570 MAG TOMAHAWK |

| Cooling | Lian Li Galahad 360mm AIO |

| Memory | 32 GB G.Skill Trident Z F4-3733 (4x 8 GB) |

| Video Card(s) | Gigabyte RTX 3070 Ti |

| Storage | Boot: Transcend MTE220S 2TB, Kintson A2000 1TB, Seagate Firewolf Pro 14 TB |

| Display(s) | Acer Nitro VG270UP (1440p 144 Hz IPS) |

| Case | Lian Li O11DX Dynamic White |

| Audio Device(s) | iFi Audio Zen DAC |

| Power Supply | Seasonic Focus+ 750 W |

| Mouse | Cooler Master Masterkeys Lite L |

| Keyboard | Cooler Master Masterkeys Lite L |

| Software | Windows 10 x64 |

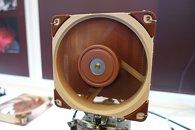

Noctua, a company well-known for the performance and acoustic characteristics of their fans (and especially for their love-it-or-hate-it brown and tan fan color scheme) has showcased their next-generation A-series fans, which took the company more than four years and 200 test designs to achieve. This is surely a case of discovering how to not make a product in 200 different ways. Noctua only had to get it right once; and it would seem they did.

Noctua are promising unparalleled performance at the A-Series noise levels. The reasons for this are varied, but one of them - perhaps the most important - comes from the fact that Noctua has ditched PBT - the plastic most commonly used in this kind of products - for a completely new compound, which the company calls Sterrox. Sterrox is a liquid crystal polymer of the same family as Kevlar. This means it has an ordered molecular structure (whereas PBT manifests a chaotic one), which means Sterrox is a much more rigid compound. This helps the fans keep their shape after spinning for long periods of time - something which happens with PBT-made fans. The chaotic structure and lower rigidity means the material deforms due to the centrifugal forces, effectively elongating the fan blades (an effect dubbed impeller creep), which means usual fan designs have to take this into account, usually by increasing the gap between the frame and the fan blades. Noctua aimed for a 0.5 mm tip clearance (much lower than the usual 1.5 or 2 mm), which results in much better air and noise performance. A narrower gap means that less air leaks through it back to the front of the fan, which allows more air to be pushed through heatsinks and radiators. And the fact that the fan blades are more rigid means they don't suffer microscopic wobbles and vibrations on the surface when spinning - hence, quieter. But how good are these new fans, really?

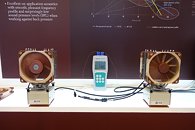

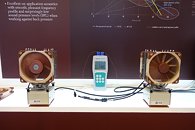

Well, apparently they're twice as good as Noctua's own NF-F12 fans. The company showed at Computex 2017 how a single A-series fan achieved identical temperatures to a setup which used two NF-F12 fans on the same processor, workload, and heatsink. And we thought the NF-F12 were good already.

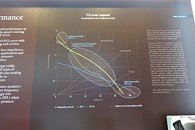

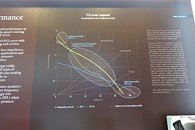

The company is also trying to blur the line with consumer's expectations regarding static pressure and airflow measurements, saying that their new A-series, while not as good on paper as their specialized fans on either metric, can easily beat both on realistic scenarios. Noctua's Jakob Dellinger says these 120 mm will even outperform most 140 mm fans when released, and that the company will be launching an adapter so users can use these A-series fans on 140 mm fittings. Apparently, there's more to increasing a fan size than just adding an extra 20 mm to the molds. Expect these fans to cost more than Noctua's NF-F12, due to the fact that Sterrox, the compound used in their manufacturing, is four times more expensive than common PBT.

View at TechPowerUp Main Site

Noctua are promising unparalleled performance at the A-Series noise levels. The reasons for this are varied, but one of them - perhaps the most important - comes from the fact that Noctua has ditched PBT - the plastic most commonly used in this kind of products - for a completely new compound, which the company calls Sterrox. Sterrox is a liquid crystal polymer of the same family as Kevlar. This means it has an ordered molecular structure (whereas PBT manifests a chaotic one), which means Sterrox is a much more rigid compound. This helps the fans keep their shape after spinning for long periods of time - something which happens with PBT-made fans. The chaotic structure and lower rigidity means the material deforms due to the centrifugal forces, effectively elongating the fan blades (an effect dubbed impeller creep), which means usual fan designs have to take this into account, usually by increasing the gap between the frame and the fan blades. Noctua aimed for a 0.5 mm tip clearance (much lower than the usual 1.5 or 2 mm), which results in much better air and noise performance. A narrower gap means that less air leaks through it back to the front of the fan, which allows more air to be pushed through heatsinks and radiators. And the fact that the fan blades are more rigid means they don't suffer microscopic wobbles and vibrations on the surface when spinning - hence, quieter. But how good are these new fans, really?

Well, apparently they're twice as good as Noctua's own NF-F12 fans. The company showed at Computex 2017 how a single A-series fan achieved identical temperatures to a setup which used two NF-F12 fans on the same processor, workload, and heatsink. And we thought the NF-F12 were good already.

The company is also trying to blur the line with consumer's expectations regarding static pressure and airflow measurements, saying that their new A-series, while not as good on paper as their specialized fans on either metric, can easily beat both on realistic scenarios. Noctua's Jakob Dellinger says these 120 mm will even outperform most 140 mm fans when released, and that the company will be launching an adapter so users can use these A-series fans on 140 mm fittings. Apparently, there's more to increasing a fan size than just adding an extra 20 mm to the molds. Expect these fans to cost more than Noctua's NF-F12, due to the fact that Sterrox, the compound used in their manufacturing, is four times more expensive than common PBT.

View at TechPowerUp Main Site

Last edited by a moderator: