Raevenlord

News Editor

- Joined

- Aug 12, 2016

- Messages

- 3,755 (1.18/day)

- Location

- Portugal

| System Name | The Ryzening |

|---|---|

| Processor | AMD Ryzen 9 5900X |

| Motherboard | MSI X570 MAG TOMAHAWK |

| Cooling | Lian Li Galahad 360mm AIO |

| Memory | 32 GB G.Skill Trident Z F4-3733 (4x 8 GB) |

| Video Card(s) | Gigabyte RTX 3070 Ti |

| Storage | Boot: Transcend MTE220S 2TB, Kintson A2000 1TB, Seagate Firewolf Pro 14 TB |

| Display(s) | Acer Nitro VG270UP (1440p 144 Hz IPS) |

| Case | Lian Li O11DX Dynamic White |

| Audio Device(s) | iFi Audio Zen DAC |

| Power Supply | Seasonic Focus+ 750 W |

| Mouse | Cooler Master Masterkeys Lite L |

| Keyboard | Cooler Master Masterkeys Lite L |

| Software | Windows 10 x64 |

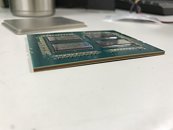

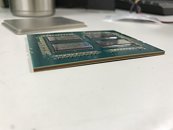

Overclocker extraordinaire der8auer, who was one of the most vocal enthusiasts calling out for better VRM designs on Intel's X299 platform (and who worked with ASUS on redesigning the VRM cooling in its motherboards) has gone and done it: he delidded a Ryzen Threadripper CPU. And this delidding went on to deliver the goods: Ryzen Threadripper delidded is EPYC (pun intended.)

Instead of the expected MCM composed of two dies (with two CCXs of four cores per die, delivering the 16 cores we were expecting), Ryzen Threadripper is actually a much more interesting chip: it seems to be a full fledged EPYC chip, with four dies of eight cores. According to der8auer, when questioned, AMD confirmed that 16-core Threadripper 1950X CPUs are configured with two working eight core dies (four CCXs of four cores each), while the other eight-core dies are disabled by AMD.

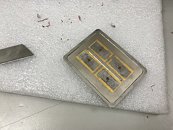

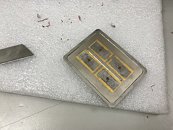

A very, very interesting question here is whether these are actually defective or just disabled by AMD, which is something the company is naturally mum about. With AMD's history of core unlocking, and the fact that Zen-based CPUs have high yields, we can certainly hope (maybe even expect) that not all disabled cores are non-functional, and that AMD had to disable some of them so as to achieve their SKU core-count. Whether or not those will be unlockable, though, is anybody's guess. Der8auer also found that AMD Threadripper dies are gold plated on the inside, so as to improve conditions and adherence of the indium solder AMD used (some users might say that while Intel uses cheap TIM on their HEDT, X299 CPUs, AMD even sells these with gold inside.) This fact naturally also opens the question of future platform scalability - AMD can certainly decide to just up available maximum core-count on their Threadripper line of CPUs (we still have at least 4 model numbers above the 1950X, an potentially more.)

Check Der8auer's delidding video on YouTube below.

View at TechPowerUp Main Site

Instead of the expected MCM composed of two dies (with two CCXs of four cores per die, delivering the 16 cores we were expecting), Ryzen Threadripper is actually a much more interesting chip: it seems to be a full fledged EPYC chip, with four dies of eight cores. According to der8auer, when questioned, AMD confirmed that 16-core Threadripper 1950X CPUs are configured with two working eight core dies (four CCXs of four cores each), while the other eight-core dies are disabled by AMD.

A very, very interesting question here is whether these are actually defective or just disabled by AMD, which is something the company is naturally mum about. With AMD's history of core unlocking, and the fact that Zen-based CPUs have high yields, we can certainly hope (maybe even expect) that not all disabled cores are non-functional, and that AMD had to disable some of them so as to achieve their SKU core-count. Whether or not those will be unlockable, though, is anybody's guess. Der8auer also found that AMD Threadripper dies are gold plated on the inside, so as to improve conditions and adherence of the indium solder AMD used (some users might say that while Intel uses cheap TIM on their HEDT, X299 CPUs, AMD even sells these with gold inside.) This fact naturally also opens the question of future platform scalability - AMD can certainly decide to just up available maximum core-count on their Threadripper line of CPUs (we still have at least 4 model numbers above the 1950X, an potentially more.)

Check Der8auer's delidding video on YouTube below.

View at TechPowerUp Main Site

Last edited: