5

5

BitFenix Whisper Series 850 W Review

Load Regulation, Hold-up Time & Inrush Current »A Look Inside & Component Analysis

Before reading this page, we strongly suggest a look at this article, which will help you understand the internal components of a PSU much better. Our main tool for the disassembly of the PSU is a Thermaltronics TMT-9000S soldering and rework station. It is of extreme quality and is equipped with a matching de-soldering gun. With such equipment in hand, breaking apart every PSU is like a walk in the park!| Bitfenix BWG850M Parts Description | |

|---|---|

| General Data | |

| Manufacturer (OEM) | CWT |

| Platform Model | G08-FGPU160-PA00 REV. A |

| Primary Side | |

| Transient Filter | 4x Y caps, 2x X caps, 2x CM chokes, 1x MOV, 1x CAP004DG |

| Bridge Rectifier(s) | 1x GBU15L06 (600V, 15A @ 115°C) |

| Inrush Current Protection | NTC Thermistor & Relay |

| APFC Mosfets | 2x Champion GP28S50G (500V, 28A @ 150°C, 0.125 Ohm) |

| APFC Boost Diode | 1x CREE IDH08G65C5 (650V, 8A @ 145°C) |

| Hold-up Cap(s) | 1x Nippon Chemi-Con (400V, 680uF, 105°C, KMR series, 2000h @ 105°C) |

| Main Switchers | 2x ROHM R6030ENX (600V, 16.3A @ 100°C, 0.13Ω @ 25°C) |

| APFC Controller | Champion CM6502S & CM03X Green PFC controller |

| Switching Controller | Champion CM6901 |

| Topology | Primary side: Half-Bridge Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V | 6x Sinopower SM4021NAKP (40V, 100A @ 100°C, 1.6mΩ) |

| 5V & 3.3V | DC-DC Converters: 2x UBIQ QM3006D FETs (30V, 57A @ 100°C, 5.5mΩ), 2x UBIQ QM3016D FETs (30V, 68A @ 100°C, 4mΩ) PWM Controller: ANPEC APW7159C |

| Filtering Capacitors | Electrolytics: Chemi-Con (105°C, KY series, KZE series, KMG series) Polymers: FPCAP (Japan) |

| Supervisor IC | Sytronix ST9S429-PG14 (OCP [2x 12V channels, OVP, UVP, PG) & Weltrend WD7518D (OCP [2x 12V channels], SCP) |

| Fan Model | Martech DF1352512SEHN (135 mm, 12 V, 0.60 A, 2000 RPM, Hydro Dynamic Bearing) |

| 5VSB Circuit | |

| Standby PWM Controller | TinySwitch-LT TNY177PN (18W Peak) |

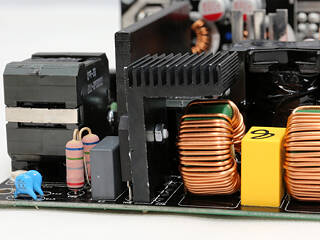

The Whisper units are based on a Channel Well Technology (CWT) platform code-named "GPU." This is a brand new platform with some similarities to CWT's GPS platform the newer Enermax Revolution X't units use. The primary side uses a half-bridge topology with an LLC resonant converter, and we find a synchronous design with a couple DC-DC converters for the generation of the minor rails in the secondary side. The design is clean, and the secondary side is free of power cables and large heatsinks which would block airflow to such sensitive parts as the electrolytic caps. Moreover, there is the rather small main transformer for a 850 W PSU, which means it probably uses a special design to handle such high power levels.

The first part of the transient filter starts at the AC receptacle with two Y caps and an X cap, and here, the power cables are also wrapped around a ferrite ring to suppress EMI. The second part of the transient filter is on the main PCB and consists of an X cap, two Y caps after the bridge rectifier, two CM chokes, and an MOV. There is also a CAP004DG on the solder side of the main PCB; it is used to block current through the X capacitor's discharge resistors when AC voltage is connected to increase efficiency slightly since no energy is wasted on bleeding resistors.

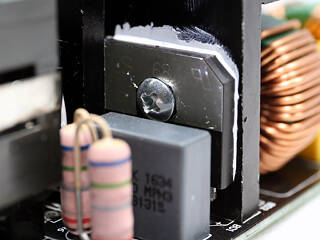

The single bridge rectifier, a GBU15L06, is on a dedicated heatsink.

There is of course an NTC thermistor to suppress large inrush currents. Since this is a Gold-certified PSU, a relay is used to bypass this thermistor when the start-up phase finishes. This relay doesn't only boost efficiency slightly, but allows the thermistor to cool down faster in order to be more effective.

The APFC converter uses a couple Champion GP28S50G FETs and a single CREE IDH08G65C5 boost diode. The bulk cap is provided by Nippon Chemi-Con (400V, 680uF, 105°C, KMR series, 2000h @ 105°C) and its capacity looks low for a PSU with a capacity of 850 W.

The PFC controller is a Champion CM6502S, and it is supported by a CM03X Green PFC controller.

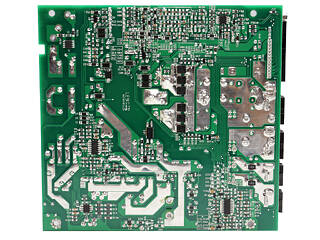

The primary FETs are two ROHM R6030ENXs in a half-bridge topology. They are supported by an LLC resonant converter for increased efficiency. The resonant controller is a Champion CM6901 on the PCB's solder side.

The two small heatsinks in the secondary side don't hold any FETs since they are on the other side of the PCB. A total of six Sinopower SM4021NAKP FETs regulate the +12V rail.

Both electrolytic and polymer caps filter the +12V rail, with the former from Chemi-Con and the latter from FPCAP. All electrolytic caps are rated at 105°C, and we mostly found KY and KZE caps, but also spotted a KRG cap, which does have a shorter lifetime than the other Chemi-Con caps.

Both DC-DC converters are on a vertical board. In total, two UBIQ QM3006D and two QM3016D FETs are used, and the single PWM controller is an ANPEC APW7159C IC.

We find two supervisor ICs on the main PCB, a Sytronix ST9S429-PG14 (OCP [2x 12V channels, OVP, UVP, PG) and a Weltrend WD7518D (OCP [2x 12V channels], SCP). Two supervisor ICs had to be installed since this PSU features four +12V rails and CWT for its own reasons didn't want to use a supervisor IC with four +12V channels.

The standby PWM controller is a TinySwitch-LT TNY177PN capable of providing up to 18 W of power with a wide voltage input range if cooled properly.

At the front of the modular PCB are a number of polymer FPCAP capacitors for an extra layer of ripple suppression.

The soldering quality is quite good overall. Among others, we also found a UTC LM393G on this side, a dual differential comparator that is probably utilized by some of the PSU's protection features.

The cooling fan is by Martech; its model number is DF1352512SEHN (135 mm, 12 V, 0.60 A). It uses a hydro dynamic bearing, which our sources say to last for 30,000h at 25 °C. HDB fans usually last much longer. The PSU's fan also doesn't utilize a semi-passive mode, which isn't necessarily a bad thing since hydro dynamic bearings suffer from more friction during their start-up phase; that is, until the lubricant has been pumped all the way up to the bearing's top. Lastly, there is the fan's control circuit with a UTC 2SA928AL transistor, which is usually used as an audio amplifier, at least according to Unisonic.

Feb 23rd, 2025 18:26 EST

change timezone

Latest GPU Drivers

New Forum Posts

- 16TB (7)

- RDNA4 Prediction Time Part Deux!!! (30)

- Gigabyte AORUS RTX5080 Missing 16 ROP's (22)

- Will undervolting a 4090 keep the connector from melting? A discussion about electrical theory. (30)

- Keep a 4080s or take a 5070ti? (43)

- EFI partition too small, can't update Windows 11 on laptop (11)

- Dune: Awakening benchmark - post your results (16)

- First ever PC build (17)

- Share your AIDA 64 cache and memory benchmark here (3022)

- Testing max ram overclock pn Ryzen 1700 (71)

Popular Reviews

- MSI GeForce RTX 5070 Ti Ventus 3X OC Review

- ASUS GeForce RTX 5070 Ti TUF OC Review

- Ducky One X Inductive Keyboard Review

- Galax GeForce RTX 5070 Ti 1-Click OC White Review

- darkFlash DY470 Review

- MSI GeForce RTX 5070 Ti Vanguard SOC Review

- Gigabyte GeForce RTX 5090 Gaming OC Review

- MSI GeForce RTX 5070 Ti Gaming Trio OC+ Review

- Palit GeForce RTX 5070 Ti GameRock OC Review

- Fantech Aria II Pro Review

Controversial News Posts

- NVIDIA GeForce RTX 5090 Spotted with Missing ROPs, NVIDIA Confirms the Issue, Multiple Vendors Affected, RTX 5070 Ti, Too (444)

- AMD Radeon 9070 XT Rumored to Outpace RTX 5070 Ti by Almost 15% (302)

- AMD Plans Aggressive Price Competition with Radeon RX 9000 Series (271)

- AMD Radeon RX 9070 and 9070 XT Listed On Amazon - One Buyer Snags a Unit (247)

- Edward Snowden Lashes Out at NVIDIA Over GeForce RTX 50 Pricing And Value (241)

- AMD Denies Radeon RX 9070 XT $899 USD Starting Price Point Rumors (239)

- NVIDIA Investigates GeForce RTX 50 Series "Blackwell" Black Screen and BSOD Issues (225)

- New Leak Reveals NVIDIA RTX 5080 Is Slower Than RTX 4090 (215)