14

14

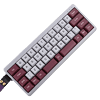

Epomaker TH40 Wireless Mechanical Keyboard Review

Software »Disassembly

Given the hot-swappable nature of the switches and this being my first time with these switches, it only made sense to take one of the Epomaker Wisteria switches apart. This is a linear switch with a factory-lubed stem that is made of a POM and PTFE composite, with the top housing made of polycarbonate and the bottom housing composed of nylon 66. There's a newer Wisteria v2 linear switch with a condenser lens added to better diffuse light from SMD LEDs underneath, whereas this older version does not get that treatment. The spring is longer than usual at 20.4 mm and the switch design is otherwise similar to other such Cherry MX-style switches in that the stem pushes the copper contacts in the bottom housing together to initiate switch actuation that is read by the microcontroller on the keyboard.

Disassembly of the Epomaker TH40 requires separation of the two plastic case panels that are held in place using interlocking plastic tabs. Use a thin flat object to pry them apart, noting that you may well leave marks on the plastic doing so, until you can completely remove the top panel off. The plate/PCB piece is connected to a daughter board in the bottom panel that has the Type-C connector and the 3-way switch. There is a second cable going to the 3000 mAh battery placed in the bottom panel—this seems a sufficient size for a 40% keyboard, especially noting the keycaps are opaque and the LEDs aren't doing much for productivity.

There is a foam sheet glued to the back of the PCB, which helps dampen keystrokes, minimizes reverberations in the bottom case panel, and also acts as a tape mod. The issue is this sheet can't be easily removed; it simply tears when you try to take it off. This leaves little modding potential to the keyboard, let alone the ability to easily separate the plate and PCB to, say, replace or re-lube the stabilizers. The same foam is cut into strips and used as gaskets to try and make this seem like a gasket mount. In practice, some of them are applied poorly at an angle and the foam pieces are just too soft to really be useful. This feels more like a weak attempt to market the TH40 as a gasket mount keyboard than anything else. Another place that Epomaker has saved money is with the use of cheap JWICK hot-swap sockets, which I am not a fan of. These have reduced compatibility with some switches, especially those with thicker pins and contacts, and I've seen some simply not register hot-swapping after a few months. The foam sheet otherwise prevents me from finding what hardware drivers are used on the PCB, and all I can say is there's another of those same foam sheets between the plate and the PCB.

Before we move on, be advised that disassembly may void the warranty and that TechPowerUp is not liable for any damages incurred if you decide to go ahead and do so anyway.

Jan 30th, 2025 18:08 EST

change timezone

Latest GPU Drivers

New Forum Posts

- Testing max ram overclock pn Ryzen 1700 (30)

- RTX5090 GPU waterblocks, post your findings here. (23)

- Regular BIOS for Radeon 470 Saphire Mining card (1)

- RTX 5080 - premature review - it sucks (129)

- why is Multiplane Overlay (MPO) disabled by default in new versions of NVCleanstall ? (0)

- Ghetto Mods (4542)

- Folding competition is LIVE. Help us please (11)

- Possible to use NVCleanstall but also use Nvidia App? (24)

- RANT- front panel connectors are a crime against pc builders/users (61)

- Advice for DDR5 CU-DIMM 2 x 24gb 8400mhz (1)

Popular Reviews

- NVIDIA GeForce RTX 5080 Founders Edition Review

- NVIDIA DLSS 4 Transformer Review - Better Image Quality for Everyone

- ASUS GeForce RTX 5090 Astral OC Review - Astronomical Premium

- NVIDIA GeForce RTX 5090 Founders Edition Review - The New Flagship

- Galax GeForce RTX 5080 1-Click OC Review

- MSI GeForce RTX 5090 Suprim SOC Review

- MSI GeForce RTX 5090 Suprim Liquid SOC Review

- KLEVV URBANE V DDR5-7600 32 GB CL36 Review

- Palit GeForce RTX 5090 GameRock Review

- NVIDIA GeForce RTX 5090 PCI-Express Scaling

Controversial News Posts

- NVIDIA 2025 International CES Keynote: Liveblog (470)

- AMD Debuts Radeon RX 9070 XT and RX 9070 Powered by RDNA 4, and FSR 4 (349)

- AMD is Taking Time with Radeon RX 9000 to Optimize Software and FSR 4 (251)

- AMD Denies Radeon RX 9070 XT $899 USD Starting Price Point Rumors (227)

- AMD Radeon RX 9070 XT & RX 9070 Custom Models In Stock at European Stores (226)

- NVIDIA GeForce RTX 5090 Features 575 W TDP, RTX 5080 Carries 360 W TDP (217)

- New Leak Reveals NVIDIA RTX 5080 Is Slower Than RTX 4090 (214)

- AMD's Radeon RX 9070 Launch Faces Pricing Hurdles (175)