- Joined

- Aug 16, 2005

- Messages

- 26,854 (3.82/day)

- Location

- Alabama

| System Name | RogueOne |

|---|---|

| Processor | Xeon W9-3495x |

| Motherboard | ASUS w790E Sage SE |

| Cooling | SilverStone XE360-4677 |

| Memory | 128gb Gskill Zeta R5 DDR5 RDIMMs |

| Video Card(s) | MSI SUPRIM Liquid X 4090 |

| Storage | 1x 2TB WD SN850X | 2x 8TB GAMMIX S70 |

| Display(s) | 49" Philips Evnia OLED (49M2C8900) |

| Case | Thermaltake Core P3 Pro Snow |

| Audio Device(s) | Moondrop S8's on schitt Gunnr |

| Power Supply | Seasonic Prime TX-1600 |

| Mouse | Lamzu Atlantis mini (White) |

| Keyboard | Monsgeek M3 Lavender, Moondrop Luna lights |

| VR HMD | Quest 3 |

| Software | Windows 11 Pro Workstation |

| Benchmark Scores | I dont have time for that. |

I wasn't happy with my 13900K temps and bought a delid kit w/ IHS copper upgrade. However knowing the KS was going to come out I figured I would just wait and held onto it.

My 13900KS came in today, and as this was going to be a CPU swap I decided that instead of installing it twice, we were just going to roll the dice and open the box and just proceed immediately. Total time of ownership before beginning? about 15min.

I do things.

www.techpowerup.com

www.techpowerup.com

Anyway lets get to it.

Rockitcool kit

Thermal Grizzley Conductonaut

Starbond

Heatgun

Thats about it.

Diving right in, the processor itself pulled out of its box.

We can't get too attached so to the garage we go. We will need to set the CPU down and prep our workstation. I took my super charger out yesterday, so we don't have a lot of room. That's ok though prep is most of the work and the lack of it is why most people fail.

First we need to get our heatgun plugged in and ready, so I grabbed the old wagner, mine was covered with hydraulic fluid, but yours doesnt have to be.

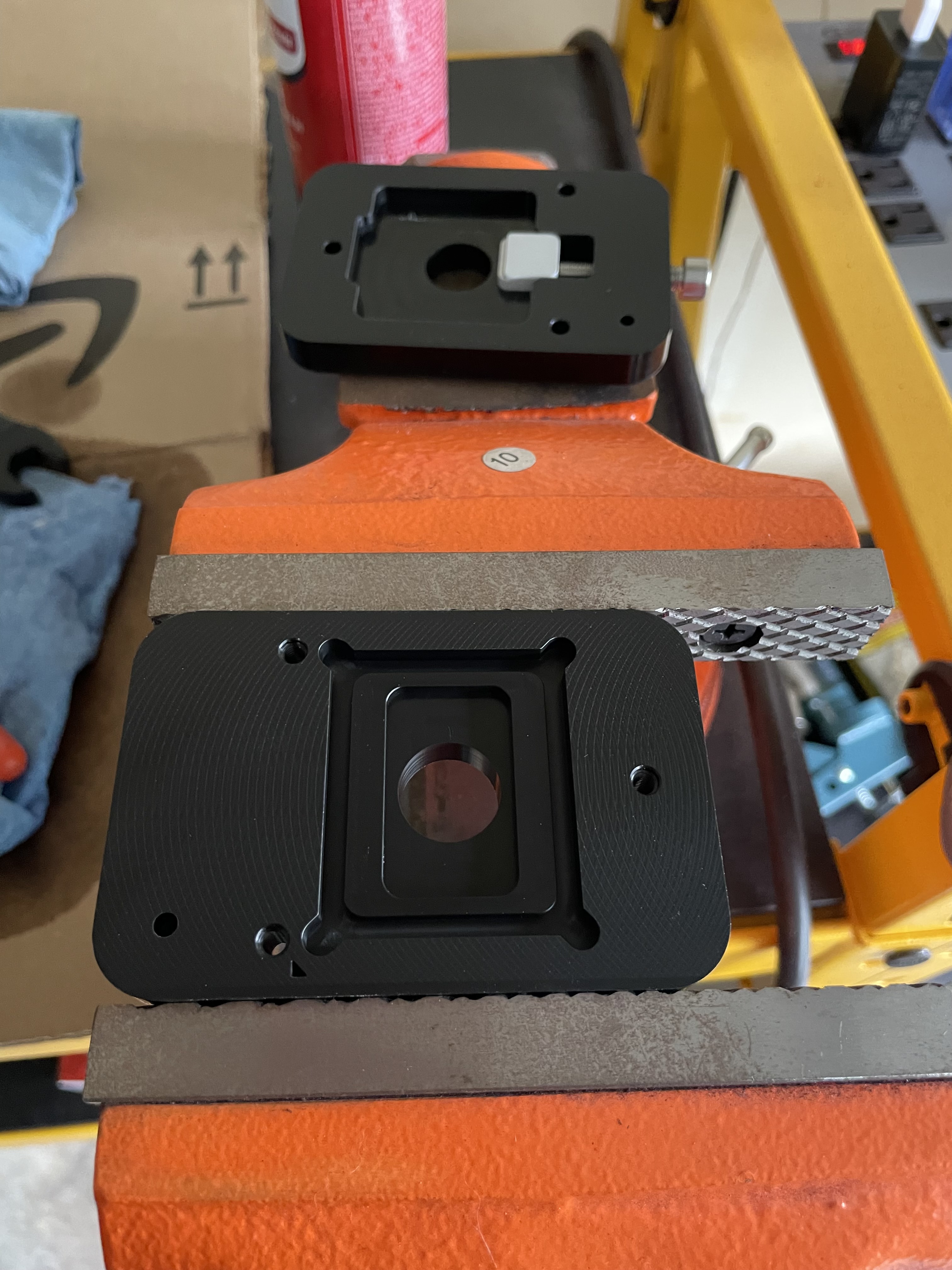

Next we need to find a place to hold the chip. I dont have any surfaces that aren't covered in engine parts right now, so bench vice it is. We will do it "arrow" to the bottom left. This way I have easy tool access to the adjustment bolt and because we need to make sure the IHS slides off the correct side or we will destroy the caps

Now lets test fit the CPU so we can logically double check and visually confirm we are pushing the IHS off in the correct direction. We will also mock setup the top cover to make sure the push mechanism is aligned properly so we dont need to waste time on bolt turns. We dont need to go super fast, but the clock will be running.

/shrug seems legit. Now that we have test fit everything we will put our wrenches and bolts to the side in preparation. Then its time to get started. We are gonna keep this only a few inches away, and only for a few min. I set my gun to "high" but I dont have a temp range, I just warm things up a lot.

Now the tool is a polymer, so it can take more of a beating then those melty KB keys you have because you let your cig fall into it. We do still need to be careful though.

Now that the chip has third degree burns its time to get some of our own, remember Upham you gotta be johnny on the spot with the screws, take your time but be DILIGENT the clock is against you, but the thermal soak will keep it liquid for a little.

Once the top is on, Get to cranking, this is the important part, this is a CPU not your GF she might be satisfied with 20seconds but with this we need to break the epoxy. Our enemy is the solder if it hardens, but right now its like mayonnaise, the thing that is fighting us is the epoxy/rtv type material they use. This does NOT melt, it just gets soft but it is like cement. So when we are cranking down we will encounter HEAVY resistance, but keep CONSTANT SLOW pressure. Thats the trick, dont treat it like a ratchet and turn it 1/4 turn in .03 nano seconds. We want to start and slowly apply one smooth slow turn with even pressure.

You will hear some cracks and pings. If it sounds like gravel congrats you turned your core back into sand. If it sounds like your grandmas mercury sable cooling down in the walmart parking lot keep going. Eventually you will hear a plop type sound and the IHS will freely move. If you took a swig to stop the shakes before you did this, it will look like this.

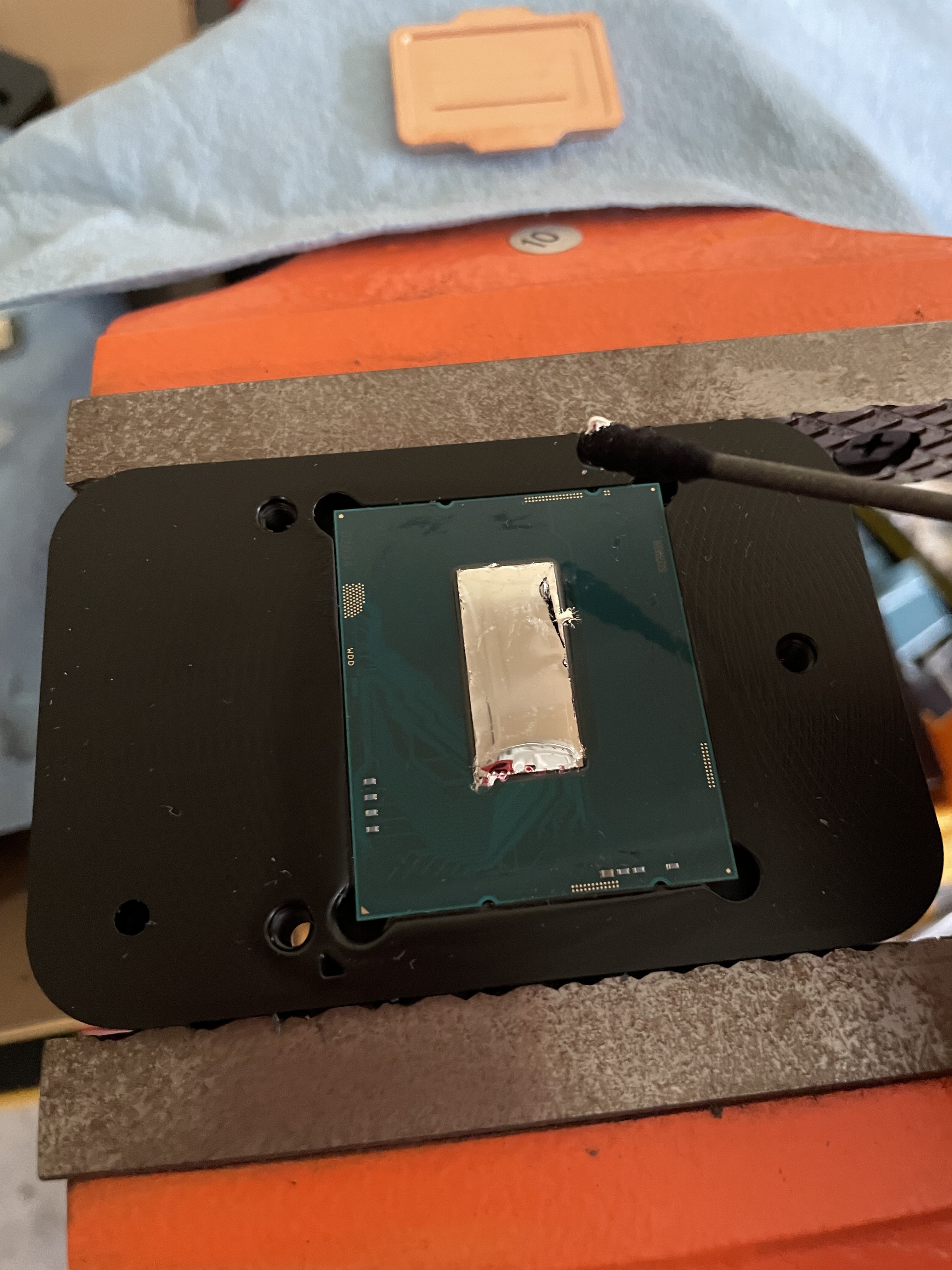

Remove it for a surprise

Yay and the IHS

Nice! So now that you probably heave a dead CPU its time to take the half a chopstick they gave you and use physics to rub it off, I'm sure you neckbeards will nail this part.

Once thats done we need to surround the core with tape. It doesnt matter what you use, we will clean everything after. The kit comes with what rockitcool calls "quick silver" now since "quick silver" is technically mercury and that isnt what they are giving you I can only assume this some kind of gallium compound. Now I know judging by the thermal threads here most of you may have failed high school earth science, but basically we are taking a higher concentration than what you would find in say conductonaut and using it to dissolve the indium solder used on the stock IHS. Some of this has cooled onto the silicon core. So we will use their included abrasive Q-tips and smear this all over the die and rub it off.

Now this has some nasty effects, so like above we are going to protect the rest of the CPU by taking it off. Use the tip of the chopstick they gave you to apply some gentle pressure and a crease around the core. This will help prevent any leaks under it. We do NOT want this to touch anything else on the CPU.

Now we cant and wont use this for thermal paste, so use the while damn syringe. I chose not to do my IHS because well, I have a replacement and I dont care. Once it is on, you need to agitate it, come on I wont do your homework for you. Agitating it will increase the speed at which this dissolves, and that will be apparent by the film that soon forms on the top of the gallium we add. In this pic you can see all of this. You can see the film, you can see I covered it in the stuff, and you can see me smearing some away, showing you that it is dissolved.

Now the applicator is abrasive, so if you have a DEX stat higher than 5 this will feel like a light grit sand paper to you, but you need to differentiate between solder still on the core and the feeling of the applicator itself. We need ALL OF IT OFF or you are going to destroy it , but its alright. Its probably already broken.

, but its alright. Its probably already broken.

Alright so you have managed to get all the indium off. Sweet. Now wipe it all away. At this point we are going to clean and re-tape the CPU because now we must polish the die with the included cream. You ever waxed a car or done body work? Then you know. Dollop that shit on a towel and start rubbing. Apply some pressure, but this is not a sand. The chemical reacts to the residue on the core and you will see black tarnish immediately. Keep going. I did it twice. Half the pack rubbed it until it was dry black goo then wiped it clean and did it again with the last of it.

Now that your done polishing, the die should look like a mirror. Congrats your ugly. Now we need to apply the conductonaut on the new IHS and the die.

Wow that looks like a lot! Yeah it isnt, but its more than you would have put on, which is too little.

After you get the LM applied to the IHS prepare your tools once again and grab the pressure plate included. We need to have all of this ready because as seen in the photo we will be applying some glue. You can use any kind of super glue you want. I use CA glue. This is used for model kits mostly and delicate work. Its very runny by nature but does come in grades and phases like Gel, or heavy med light. Anyway, this shit sets QUICK so be ready.

Just dont use elmers glue, you only eat that. Have some after you done, you did a good job. Dont use RTV either. That worked on some of my older CPU mods but the clearences are too small now. It doesnt matter where you apply it. I did the winglets but you can do the corners. Just dont go wild.

Anyway, once you put a little on the IHS its time to set it and align it in the tool. This will let the IHS sit how it would from factory geometry wise. Just be careful about the SMDs! Remember, just like the heating part. patient, but brisk. Do not rush.

Once its in place bolt on your clamp assembly. Remember this is all one go. You are aligning and clamping all in sequence. Do not stop.

Now the big bolt looks mighty scary but its plastic. You dont even use the tool. You just hand tighten it until its firm and let it sit. I would do it for 5-15min. It was cold so I decided 15 even though its a quick bond glue and went and got my rig ready for the transplant.

Anyway now that 15min have gone by your ready to find out you killed it. Remember dont RMA, that makes you a scumbag and raises costs. You did this.

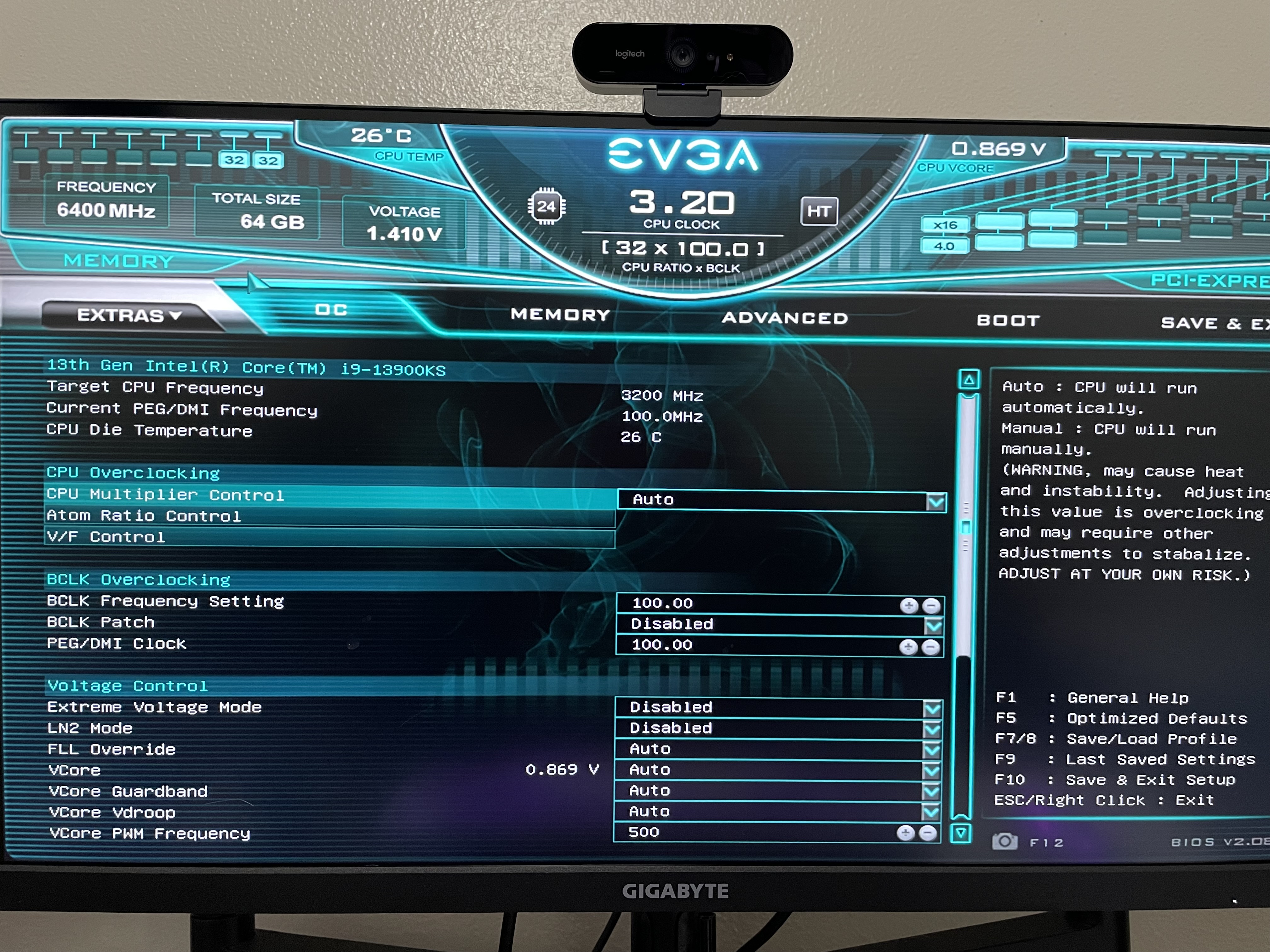

Woot it booted! Congrats your marriage is still in shambles. Watch your temps, but if you took your time everything should be fine.

Q/A

Q: Why did you do this?? AMD and intel and the KS :froth-at-mouth:

A: Because I wanted to. TPU is not about fortnight FPS or arguing over AMD vs Intel. TPU was and is first and foremost a tech enthusiast forum and I did this because I wanted too.

Q: Why LM? I heard from %member% in %thread% that LM is for non-religious people and will hurt your computer.

A: wack all of my PCs and delids still work and run cool.

Q: You replaced a K with a KS why?

A: You already have a few threads where people eat crayons and bitch about just this. This thread isnt that.

My temps would hit 90 all the time in game on my K. I would reach 100ºC during heavy workloads causing throttle. I imagine by no stretch my KS would do the same.

Under the same work load I now max at 77ºC.

It seems counter intuitive, but this was actually written this way on purpose. The forums over time have shifted and dont include projects like this as much anymore from what I have seen. In many threads people that do this are generally ripped to shreds by die hards that think this kind of thing is the end of the world. Writing it in a devil may care fashion was part of the whole presentation. My other guides are alot more astute and formal.

Thanks for reading!

My 13900KS came in today, and as this was going to be a CPU swap I decided that instead of installing it twice, we were just going to roll the dice and open the box and just proceed immediately. Total time of ownership before beginning? about 15min.

I do things.

7980xe Delid

Thanks to @Xx Tek Tip xX a few months ago for pointing me in the right direction. (I was originally going to do bare die but was advised instead to just to an IHS delid. Its been a bit but finally got around to it. Ambient Temp: 22ºC CPU Clock: 4.5ghz all cores Test: Intel XTU 15min stress...

Anyway lets get to it.

Rockitcool kit

Thermal Grizzley Conductonaut

Starbond

Heatgun

Thats about it.

Diving right in, the processor itself pulled out of its box.

We can't get too attached so to the garage we go. We will need to set the CPU down and prep our workstation. I took my super charger out yesterday, so we don't have a lot of room. That's ok though prep is most of the work and the lack of it is why most people fail.

First we need to get our heatgun plugged in and ready, so I grabbed the old wagner, mine was covered with hydraulic fluid, but yours doesnt have to be.

Next we need to find a place to hold the chip. I dont have any surfaces that aren't covered in engine parts right now, so bench vice it is. We will do it "arrow" to the bottom left. This way I have easy tool access to the adjustment bolt and because we need to make sure the IHS slides off the correct side or we will destroy the caps

Now lets test fit the CPU so we can logically double check and visually confirm we are pushing the IHS off in the correct direction. We will also mock setup the top cover to make sure the push mechanism is aligned properly so we dont need to waste time on bolt turns. We dont need to go super fast, but the clock will be running.

/shrug seems legit. Now that we have test fit everything we will put our wrenches and bolts to the side in preparation. Then its time to get started. We are gonna keep this only a few inches away, and only for a few min. I set my gun to "high" but I dont have a temp range, I just warm things up a lot.

Now the tool is a polymer, so it can take more of a beating then those melty KB keys you have because you let your cig fall into it. We do still need to be careful though.

Now that the chip has third degree burns its time to get some of our own, remember Upham you gotta be johnny on the spot with the screws, take your time but be DILIGENT the clock is against you, but the thermal soak will keep it liquid for a little.

Once the top is on, Get to cranking, this is the important part, this is a CPU not your GF she might be satisfied with 20seconds but with this we need to break the epoxy. Our enemy is the solder if it hardens, but right now its like mayonnaise, the thing that is fighting us is the epoxy/rtv type material they use. This does NOT melt, it just gets soft but it is like cement. So when we are cranking down we will encounter HEAVY resistance, but keep CONSTANT SLOW pressure. Thats the trick, dont treat it like a ratchet and turn it 1/4 turn in .03 nano seconds. We want to start and slowly apply one smooth slow turn with even pressure.

You will hear some cracks and pings. If it sounds like gravel congrats you turned your core back into sand. If it sounds like your grandmas mercury sable cooling down in the walmart parking lot keep going. Eventually you will hear a plop type sound and the IHS will freely move. If you took a swig to stop the shakes before you did this, it will look like this.

Remove it for a surprise

Yay and the IHS

Nice! So now that you probably heave a dead CPU its time to take the half a chopstick they gave you and use physics to rub it off, I'm sure you neckbeards will nail this part.

Once thats done we need to surround the core with tape. It doesnt matter what you use, we will clean everything after. The kit comes with what rockitcool calls "quick silver" now since "quick silver" is technically mercury and that isnt what they are giving you I can only assume this some kind of gallium compound. Now I know judging by the thermal threads here most of you may have failed high school earth science, but basically we are taking a higher concentration than what you would find in say conductonaut and using it to dissolve the indium solder used on the stock IHS. Some of this has cooled onto the silicon core. So we will use their included abrasive Q-tips and smear this all over the die and rub it off.

Now this has some nasty effects, so like above we are going to protect the rest of the CPU by taking it off. Use the tip of the chopstick they gave you to apply some gentle pressure and a crease around the core. This will help prevent any leaks under it. We do NOT want this to touch anything else on the CPU.

Now we cant and wont use this for thermal paste, so use the while damn syringe. I chose not to do my IHS because well, I have a replacement and I dont care. Once it is on, you need to agitate it, come on I wont do your homework for you. Agitating it will increase the speed at which this dissolves, and that will be apparent by the film that soon forms on the top of the gallium we add. In this pic you can see all of this. You can see the film, you can see I covered it in the stuff, and you can see me smearing some away, showing you that it is dissolved.

Now the applicator is abrasive, so if you have a DEX stat higher than 5 this will feel like a light grit sand paper to you, but you need to differentiate between solder still on the core and the feeling of the applicator itself. We need ALL OF IT OFF or you are going to destroy it

, but its alright. Its probably already broken.

, but its alright. Its probably already broken.Alright so you have managed to get all the indium off. Sweet. Now wipe it all away. At this point we are going to clean and re-tape the CPU because now we must polish the die with the included cream. You ever waxed a car or done body work? Then you know. Dollop that shit on a towel and start rubbing. Apply some pressure, but this is not a sand. The chemical reacts to the residue on the core and you will see black tarnish immediately. Keep going. I did it twice. Half the pack rubbed it until it was dry black goo then wiped it clean and did it again with the last of it.

Now that your done polishing, the die should look like a mirror. Congrats your ugly. Now we need to apply the conductonaut on the new IHS and the die.

Wow that looks like a lot! Yeah it isnt, but its more than you would have put on, which is too little.

After you get the LM applied to the IHS prepare your tools once again and grab the pressure plate included. We need to have all of this ready because as seen in the photo we will be applying some glue. You can use any kind of super glue you want. I use CA glue. This is used for model kits mostly and delicate work. Its very runny by nature but does come in grades and phases like Gel, or heavy med light. Anyway, this shit sets QUICK so be ready.

Just dont use elmers glue, you only eat that. Have some after you done, you did a good job. Dont use RTV either. That worked on some of my older CPU mods but the clearences are too small now. It doesnt matter where you apply it. I did the winglets but you can do the corners. Just dont go wild.

Anyway, once you put a little on the IHS its time to set it and align it in the tool. This will let the IHS sit how it would from factory geometry wise. Just be careful about the SMDs! Remember, just like the heating part. patient, but brisk. Do not rush.

Once its in place bolt on your clamp assembly. Remember this is all one go. You are aligning and clamping all in sequence. Do not stop.

Now the big bolt looks mighty scary but its plastic. You dont even use the tool. You just hand tighten it until its firm and let it sit. I would do it for 5-15min. It was cold so I decided 15 even though its a quick bond glue and went and got my rig ready for the transplant.

Anyway now that 15min have gone by your ready to find out you killed it. Remember dont RMA, that makes you a scumbag and raises costs. You did this.

Woot it booted! Congrats your marriage is still in shambles. Watch your temps, but if you took your time everything should be fine.

Q/A

Q: Why did you do this?? AMD and intel and the KS :froth-at-mouth:

A: Because I wanted to. TPU is not about fortnight FPS or arguing over AMD vs Intel. TPU was and is first and foremost a tech enthusiast forum and I did this because I wanted too.

Q: Why LM? I heard from %member% in %thread% that LM is for non-religious people and will hurt your computer.

A: wack all of my PCs and delids still work and run cool.

Q: You replaced a K with a KS why?

A: You already have a few threads where people eat crayons and bitch about just this. This thread isnt that.

My temps would hit 90 all the time in game on my K. I would reach 100ºC during heavy workloads causing throttle. I imagine by no stretch my KS would do the same.

Under the same work load I now max at 77ºC.

It seems counter intuitive, but this was actually written this way on purpose. The forums over time have shifted and dont include projects like this as much anymore from what I have seen. In many threads people that do this are generally ripped to shreds by die hards that think this kind of thing is the end of the world. Writing it in a devil may care fashion was part of the whole presentation. My other guides are alot more astute and formal.

Thanks for reading!

Attachments

Last edited: