- Joined

- Oct 9, 2007

- Messages

- 47,670 (7.43/day)

- Location

- Dublin, Ireland

| System Name | RBMK-1000 |

|---|---|

| Processor | AMD Ryzen 7 5700G |

| Motherboard | Gigabyte B550 AORUS Elite V2 |

| Cooling | DeepCool Gammax L240 V2 |

| Memory | 2x 16GB DDR4-3200 |

| Video Card(s) | Galax RTX 4070 Ti EX |

| Storage | Samsung 990 1TB |

| Display(s) | BenQ 1440p 60 Hz 27-inch |

| Case | Corsair Carbide 100R |

| Audio Device(s) | ASUS SupremeFX S1220A |

| Power Supply | Cooler Master MWE Gold 650W |

| Mouse | ASUS ROG Strix Impact |

| Keyboard | Gamdias Hermes E2 |

| Software | Windows 11 Pro |

Despite sticking with PCI-Express Gen 4 as its host interface, the NVIDIA GeForce RTX 4090 "Ada" graphics card standardizes the new 12+4 pin ATX 12VHPWR power connector, even across custom-designs by NVIDIA's add-in card (AIC) partners. This tiny connector is capable of delivering 600 W of power continuously, and briefly take 200% excursions (spikes). Normally, it should make your life easier as it condenses multiple 8-pin PCIe power connectors into one neat little connector; but in reality the connector is proving to be quite impractical. For starters, most custom RTX 4090 graphics cards have their PCBs being only two-thirds of the actual card length, which puts the power connector closer to the middle of the graphics card, making it aesthetically unappealing, but then there's a bigger problem, as uncovered by Buildzoid of Actually Hardcore Overclocking, an expert with PC hardware power-delivery designs.

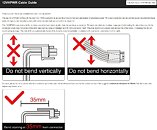

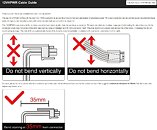

CableMod, a company that specializes in custom modular-PSU cables targeting the case-modding community and PC enthusiasts, has designed a custom 12VHPWR cable that plugs into multiple 12 V output points on a modular PSU, converting them to a 16-pin 12VHPWR. It comes with a pretty exhaustive set of dos and don'ts; the latter are more relevant: apparently, you should not try to arm-wrestle with an 12VHPWR connector: do not attempt to bend the cable horizontally or vertically close to the connector, but leave a distance of at least 3.5 cm (1.37-inch). This ensures reduced pressure on the contacts in the connector. Combine this with the already tall RTX 4090 graphics cards, and you have yourself a power connector that's impractical for most standard-width mid-tower cases (chassis), with no room for cable-management. Attempting to "wrestle" with the connector, and somehow bending it to your desired shape, will cause improper contacts, which pose a fire-hazard.

Update Oct 26th: There are multiple updates to the story.

The 12VHPWR connector is a new standard, which means most PSUs in the market lack it, much in the same way as PSUs some 17 years ago lacked PCIe power connectors; and graphics cards included 4-pin Molex-to-PCIe adapters. NVIDIA probably figured out early on when implementing this connector that it cannot rely on adapters by AICs or PSU vendors to perform reliably (i.e. not cause problems with their graphics cards, resulting in a flood of RMAs); and so took it upon itself to design an adapter that converts 8-pin PCIe connectors to a 12VHPWR, which all AICs are required to include with their custom-design RTX 4090 cards. This adapter is rightfully overengineered by NVIDIA to be as reliable as possible, and NVIDIA even includes a rather short service-span of 30 connections and disconnections; before the contacts of the adapter begin to wear out and become unreliable. The only problem with NVIDIA's adapter is that it is ugly, and ruins the aesthetics of the otherwise brilliant RTX 4090 custom designs; which means a market is created for custom adapters.

Update 15:59 UTC: A user on Reddit who goes by "reggie_gakil" posted pictures of a GeForce RTX 4090 graphics card with with a burnt out 12VHPWR. While the card itself is "fine" (functional); the NVIDIA-designed adapter that converts 4x 8-pin PCIe to 12VHPWR, has a few melted pins that are probably caused due to improper contact, causing them to overheat or short. "I don't know how it happened but it smelled badly and I saw smoke. Definetly the Adapter who had Problems as card still seems to work," goes the caption with these images.

Update Oct 26th: Aris Mpitziopoulos, our associate PSU reviewer and editor of Hardware Busters, did an in-depth video presentation on the issue, where he details how the 12VHPWR design may not be at fault, but extreme abuse by end-users attempting to cable-manage their builds. Mpitziopoulos details the durability of the connector in its normal straight form, versus when tightly bent. You can catch the presentation on YouTube here.

Update Oct 26th: In related news, AMD confirmed that none of its upcoming Radeon RX 7000 series RDNA3 graphics cards features the 12VHPWR connector, and that the company will stick to 8-pin PCIe connectors.

Update Oct 30th: Jon Gerow, aka Jonny Guru, has posted a write-up about the 12VHPWR connector on his website. It's an interesting read with great technical info.

View at TechPowerUp Main Site | Source

CableMod, a company that specializes in custom modular-PSU cables targeting the case-modding community and PC enthusiasts, has designed a custom 12VHPWR cable that plugs into multiple 12 V output points on a modular PSU, converting them to a 16-pin 12VHPWR. It comes with a pretty exhaustive set of dos and don'ts; the latter are more relevant: apparently, you should not try to arm-wrestle with an 12VHPWR connector: do not attempt to bend the cable horizontally or vertically close to the connector, but leave a distance of at least 3.5 cm (1.37-inch). This ensures reduced pressure on the contacts in the connector. Combine this with the already tall RTX 4090 graphics cards, and you have yourself a power connector that's impractical for most standard-width mid-tower cases (chassis), with no room for cable-management. Attempting to "wrestle" with the connector, and somehow bending it to your desired shape, will cause improper contacts, which pose a fire-hazard.

Update Oct 26th: There are multiple updates to the story.

The 12VHPWR connector is a new standard, which means most PSUs in the market lack it, much in the same way as PSUs some 17 years ago lacked PCIe power connectors; and graphics cards included 4-pin Molex-to-PCIe adapters. NVIDIA probably figured out early on when implementing this connector that it cannot rely on adapters by AICs or PSU vendors to perform reliably (i.e. not cause problems with their graphics cards, resulting in a flood of RMAs); and so took it upon itself to design an adapter that converts 8-pin PCIe connectors to a 12VHPWR, which all AICs are required to include with their custom-design RTX 4090 cards. This adapter is rightfully overengineered by NVIDIA to be as reliable as possible, and NVIDIA even includes a rather short service-span of 30 connections and disconnections; before the contacts of the adapter begin to wear out and become unreliable. The only problem with NVIDIA's adapter is that it is ugly, and ruins the aesthetics of the otherwise brilliant RTX 4090 custom designs; which means a market is created for custom adapters.

Update 15:59 UTC: A user on Reddit who goes by "reggie_gakil" posted pictures of a GeForce RTX 4090 graphics card with with a burnt out 12VHPWR. While the card itself is "fine" (functional); the NVIDIA-designed adapter that converts 4x 8-pin PCIe to 12VHPWR, has a few melted pins that are probably caused due to improper contact, causing them to overheat or short. "I don't know how it happened but it smelled badly and I saw smoke. Definetly the Adapter who had Problems as card still seems to work," goes the caption with these images.

Update Oct 26th: Aris Mpitziopoulos, our associate PSU reviewer and editor of Hardware Busters, did an in-depth video presentation on the issue, where he details how the 12VHPWR design may not be at fault, but extreme abuse by end-users attempting to cable-manage their builds. Mpitziopoulos details the durability of the connector in its normal straight form, versus when tightly bent. You can catch the presentation on YouTube here.

Update Oct 26th: In related news, AMD confirmed that none of its upcoming Radeon RX 7000 series RDNA3 graphics cards features the 12VHPWR connector, and that the company will stick to 8-pin PCIe connectors.

Update Oct 30th: Jon Gerow, aka Jonny Guru, has posted a write-up about the 12VHPWR connector on his website. It's an interesting read with great technical info.

View at TechPowerUp Main Site | Source