Chinese Mature Nodes Undercut Western Silicon Pricing, to Capture up to 28% of the Market This Year

Chinese manufacturers have seized significant market share in legacy chip production, driving prices down and creating intense competitive pressure that Western competitors cannot match. The so-called "China shock" in the semiconductor sector appears as mature node production shifts East at accelerating rates. Legacy process nodes, which are usually 16/20/22/24 nm and larger, form the backbone of consumer electronics and automotive applications while providing established manufacturers with stable revenue streams for R&D investment. However, this economic framework now faces structural disruption as Chinese fabs leverage domestic demand and government support to expand capacity. By Q4 2025, Chinese facilities will control 28% of global mature chip production, with projections indicating further expansion to 39% by 2027.

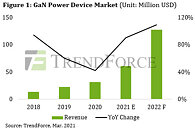

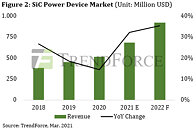

This rapid capacity growth directly results from Beijing's strategic pivot following US export controls on advanced semiconductor equipment, which redirected investment toward mature nodes where technological barriers remain lower. This is happening in parallel with companies like SMIC, although isolated, which are developing lithography solutions for cutting-edge 5 nm and 3 nm wafer production. For older nodes, The market impact appears most pronounced in specialized materials like silicon carbide (SiC). Industry benchmark 6-inch SiC wafers from Wolfspeed were previously $1,500, compared to current $500 pricing from Guangzhou Summit Crystal Semiconductor—representing a 67% price compression that Western manufacturers cannot profitably match. Multiple semiconductor firms report significant financial strain from this pricing pressure. Wolfspeed has implemented 20% workforce reductions following a 96% market capitalization decline, while Onsemi recently announced 9% staff cuts. With more Chinese expansion into the mature node category, Western companies can't keep up with the lowered costs of what is now becoming a commodity.

This rapid capacity growth directly results from Beijing's strategic pivot following US export controls on advanced semiconductor equipment, which redirected investment toward mature nodes where technological barriers remain lower. This is happening in parallel with companies like SMIC, although isolated, which are developing lithography solutions for cutting-edge 5 nm and 3 nm wafer production. For older nodes, The market impact appears most pronounced in specialized materials like silicon carbide (SiC). Industry benchmark 6-inch SiC wafers from Wolfspeed were previously $1,500, compared to current $500 pricing from Guangzhou Summit Crystal Semiconductor—representing a 67% price compression that Western manufacturers cannot profitably match. Multiple semiconductor firms report significant financial strain from this pricing pressure. Wolfspeed has implemented 20% workforce reductions following a 96% market capitalization decline, while Onsemi recently announced 9% staff cuts. With more Chinese expansion into the mature node category, Western companies can't keep up with the lowered costs of what is now becoming a commodity.