11

11

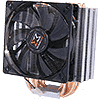

Xigmatek Aegir SD128264 Review

Installation »A Closer Look

Xigmatek's Aegir is an aluminum and copper leviathan. While the past couple of years of tower-type CPU coolers has been rather uneventful, the most recent breed has impressed, with pretty unusual shapes of aluminum fins, and passage-placement of heatpipes through those fins, to even out heat dissipation. As far as design goes, the Aegir achieves some of that, with a symmetrical design that adds to some air turbulence. The heat pipe passages are spread evenly across the fin, for better heat dissipation.

The fan latches on to the heatsink using rubber bolts. While rubber bolts do tend to offer better vibration dampening, they're a tough ask when removing or replacing.

The 120 mm fan packed with the Aegir is a high speed illuminated fan, rated to push 89.45 CFM of air. The plastic making up both the frame and and impeller are of the same type, tinted dark brown. Along the corners of the fan are white LEDs that, coupled with the brown tinted plastic of the fan, give a nice beer-like dark-brown glow to the fan, which is subjectively a lot better than an all-blue or all-red glow. Blue is so 2006.

The fan uses a standard 4-pin connector, which can connect to almost all current motherboards' CPU fan headers. It supports pulse-width modulation (PWM) method of fan-speed control, voltage-based method is naturally supported, in case you decide to plug the fan into a standard 3-pin fan header on the motherboard, instead. An increasing number of motherboards these days are letting you select between the two kinds of speed control in the BIOS setup, with the fan plugged in to the CPU fan header.

The unique selling point of the Xigmatek Aegir, is its so-called "double layer heat-pipe direct touch" (DL-HDT) arrangement of heat pipes. It is an interesting concept, indeed. When designing a tower-type heatsink, the number of heat pipes the manufacturers can pass through the CPU base making contact with the CPU, is limited by the size of the base. In this case, there are two 8 mm and two 6 mm heat pipes making direct contact with the CPU, but then the base has already run out of space for more heat pipes. Xigmatek found a novel way out of this, by making a second layer of heat pipes (two 8 mm), that make direct contact with the heat pipes below. These pipes indirectly draw heat from the CPU, but increase the amount of heat that can be transferred to the aluminum fin array above.

Xigmatek is a pioneer of CPU bases in which heat pipes make direct contact with the CPU, eliminating a base plate and any thermal resistance it may add. With the Aegir's base, you can see how the engineers at Xigmatek put some thought. Instead of having a number of smaller 6 mm heat pipes, there are two 8 mm heat pipes passing through the central portion of the base, reducing the number of crevices between the pipes and the base itself. The 6 mm heat pipes move along the periphery of the base. The central portion of the base is where the CPU die(s) is/are located. Right above those two 8 mm pipes, there is a second layer of 6 mm pipes making direct contact with them, effectively improving the heat transfer efficiency of the base at its central portion. The base is properly evened by a CNC mill and since there are just four heat pipes, there are lesser number of crevices in which thermal interface material (TIM) can seep in, causing thicker portions of the TIM layer, which in turn can insulate, rather than conduct.

May 6th, 2025 08:14 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- Choosing an Internal HDD (66)

- It's happening again, melting 12v high pwr connectors (1077)

- Why doesn't every house have solar installed? (341)

- Half Life 3 soon ? (23)

- Ventoy how to copy iso to the Ventoy drive? (4)

- RX590 - error 43 (14)

- I dont understand the phone OS world..... (207)

- New home setup or stick with powerline (6)

- Kindly help in Identifying GPU and Suitable bios (26)

- Request for advice [Big Build] (63)

Popular Reviews

- Arctic Liquid Freezer III Pro 360 A-RGB Review

- ASUS Radeon RX 9070 XT TUF OC Review

- Clair Obscur: Expedition 33 Performance Benchmark Review - 33 GPUs Tested

- ASUS ROG Maximus Z890 Hero Review

- Zotac GeForce RTX 5070 Ti Amp Extreme Review

- Upcoming Hardware Launches 2025 (Updated Apr 2025)

- Seasonic Vertex GX 850 W Review

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- ASUS GeForce RTX 5090 Astral Liquid OC Review - The Most Expensive GPU I've Ever Tested

- Montech HS02 PRO Review

Controversial News Posts

- AMD Radeon RX 9060 XT to Roll Out 8 GB GDDR6 Edition, Despite Rumors (131)

- NVIDIA Sends MSRP Numbers to Partners: GeForce RTX 5060 Ti 8 GB at $379, RTX 5060 Ti 16 GB at $429 (128)

- NVIDIA Launches GeForce RTX 5060 Series, Beginning with RTX 5060 Ti This Week (115)

- Nintendo Confirms That Switch 2 Joy-Cons Will Not Utilize Hall Effect Stick Technology (105)

- Sony Increases the PS5 Pricing in EMEA and ANZ by Around 25 Percent (84)

- Parts of NVIDIA GeForce RTX 50 Series GPU PCB Reach Over 100°C: Report (78)

- Intel "Bartlett Lake-S" Gaming CPU is Possible, More Hints Appear for a 12 P-Core SKU (77)

- China Develops HDMI Alternative: 192 Gbps Speeds and 480 W Power Delivery (74)