Monday, February 1st 2021

AMD Reportedly in Plans to Outsource Partial Chip Production to Samsung

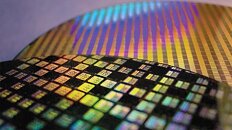

It's been doing the rounds in the rumor mill that AMD is looking to expand its semiconductor manufacturing partners beyond TSMC (for the 7 nm process and eventually 5 nm) and Global Foundries (12 nm process used in its I/O dies). The intention undoubtedly comes from the strain that's being placed on TSMC's production lines, as most foundry-less businesses outsource their wafer production to the Taiwanese companies' factories and manufacturing processes, which are currently the industry's best. However, as we've seen, TSMC is having a hard time scaling its production facilities to the unprecedented demand it's seeing from its consumers. The company also has recently announced it may prioritize new manufacturing capabilities for the automotive industry, which is also facing shortages in chips - and that certainly doesn't instill confidence in capacity increases for its non-automotive clients.

That's what originated form the rumor mill. Speculating, this could mean that AMD would be looking to outsource products with generally lower ASP to Samsung's foundries, instead of trying to cram even more silicon manufacturing onto TSMC's 7 nm process (where it already fabricates its Zen 3, RDNA 2, EPYC, and custom silicon solutions for latest-gen consoles). AMD might thus be planning on leveraging Samsung's 8 nm or even smaller fabrication processes as alternatives for, for example, lower-than-high-end graphics solutions and other product lines (such as APUs and FPGA production, should its acquisition of Xilinx come through).Take this information with a grain of salt; but all things considered, it does make sense that AMD outsources less-critical components to lesser-performing (and thus lesser-requested) manufacturing processes in a bid to keep up with demand on its best sources of revenue, without diluting their production even further. Remember that AMD does have an agreement in place with Samsung for licensing of its RDNA 2 graphics architecture for integration in the South Korean company's mobile Exynos chips.

Sources:

via Hardware Info, Twitter

That's what originated form the rumor mill. Speculating, this could mean that AMD would be looking to outsource products with generally lower ASP to Samsung's foundries, instead of trying to cram even more silicon manufacturing onto TSMC's 7 nm process (where it already fabricates its Zen 3, RDNA 2, EPYC, and custom silicon solutions for latest-gen consoles). AMD might thus be planning on leveraging Samsung's 8 nm or even smaller fabrication processes as alternatives for, for example, lower-than-high-end graphics solutions and other product lines (such as APUs and FPGA production, should its acquisition of Xilinx come through).Take this information with a grain of salt; but all things considered, it does make sense that AMD outsources less-critical components to lesser-performing (and thus lesser-requested) manufacturing processes in a bid to keep up with demand on its best sources of revenue, without diluting their production even further. Remember that AMD does have an agreement in place with Samsung for licensing of its RDNA 2 graphics architecture for integration in the South Korean company's mobile Exynos chips.

25 Comments on AMD Reportedly in Plans to Outsource Partial Chip Production to Samsung

www.extremetech.com/computing/181136-samsung-and-globalfoundries-buddy-up-for-14nm-while-ibm-heads-for-the-exit

Great read looking back. ;)

Samsung 5nm isnt being used in any big chips yet, we're stillnot sure how it would scale to such a large chip.

That being said, it's still a shame that GloFo never did risk 7nm; their was showing more potential than TSMC's in early testing, and they could have also joined AMD in a financial revival. I do wonder if they will reconsider in the coming years; as 7nm is going to remain in demand for the foreseeable future.

Now, Samsung 7nm EUV has been in production for ~2 years now. Most folks here don't know that because their head is buried in PC x86 desktop wars.

The IBM Power10 is made on that node and if a picture were used to describe 'fat, hot, powerful cpu' that would be it. 18B transistors on 602mm2 die, 30 cores with SMT8 *yes 8 threads per core*, 120MB L3 cache, and I believe I read a 400W TDP. That thing also supports DDR3, DDR4, DDR5, GDDR6, and HBM. It can have memory bandwidth up to 800GB/s vs 46GB/s for an Intel desktop CPU (using JEDEC RAM). For comparison, the 10 core SMT2 10900K is just over 200mm2 in size.

So Samsung is quite capable of making big high core count CPUs.

What happened to global foundries are they not in the picture at all anymore?

TSMC is building a new fab, or maybe more correctly a "back end process" facility. It is supposed to come online late 2021.

www.businesskorea.co.kr/news/articleView.html?idxno=52647

TSMC is also saying they expect 5nm capacity to increase from around 60,000 wafers per month to 100,000 by the end of 2021 :

www.gizchina.com/2021/01/05/tsmc-to-increase-its-5nm-production-capacity-from-60000-to-100000-per-month/

However, they are also saying that any additional capacity they get will be prioritized for automotive. The shortage is actually starting to halt auto production :

www.cnbc.com/2021/01/25/taiwan-ministry-says-tsmc-will-prioritize-auto-chips-if-possible.html

So there's a pretty clear picture of the official media line.

What I don't get, is why suddenly we don't seem to be able to use all these other fabs on 28nm / 16nm / 14nm etc. We haven't had these kinds of issues in the past, and demand in many sectors is down. I know that auto sales regressed, 2020 was quite a bit below 2019 sales. So did phone sales.

Maybe it's just the boom in PC Desktop/Laptop sales that's driving it, that affects not just CPUs but also support chipsets of all kinds like sound and network. Might also be multiple 'supercomputer' projects that suck up so much capacity.

Sure would ease comparisons too.

GF went silent after they introduced their 14nm. I don't think they have gone with the cutting edge fab.

www.digitimes.com/news/a20210204PD201.html

winfuture.de/news,121033.html

I wonder if they have publicly traded stock.

Or the extra chips could be supportive chips like the recent ML chiplet or Io die.

That aligns quite well with this news but it is. Just an opinion.