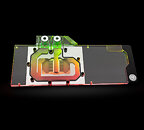

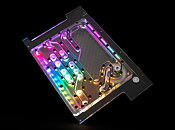

EK-Quantum Velocity² D-RGB - New LGA 1700 CPU Water Block Ready for Alder Lake

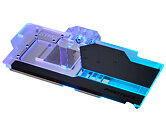

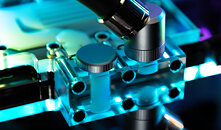

After the long reign of the most popular water block on the market, the EK-Quantum Velocity, it's time to push the boundaries yet again and step into the future. Enter the next generation EK Quantum Line water block - the EK-Quantum Velocity². The water block showcases the EK-Matrix7 initiative, a standard where increments of 7 mm manage the height of products and the distance between ports. This product uses a socket-specific cooling engine to ensure the best performance and optimal flow with low restrictions on every platform. Three years after the original Velocity water block launch, EK is officially launching the Velocity² 1700, which is engineered for the Intel LGA 1700 socket and Alder Lake series desktop processors. Other Velocity² CPU water blocks will also follow shortly, tuned specifically for each CPU socket and IHS geometry on the market.

This new water block kept the name "Velocity" because it retained the ability to be responsive and agile in the world of liquid cooling. Embedded in the Velocity² is a next-generation EK CPU water block cooling engine that is socket-specific. A combination of mounting pressure and cold plate geometry, tailored for the IHS and die layout of Intel LGA 1700 socket processors, is used to achieve low hydraulic flow restriction and high performance. Thе lathe-turned cold plate is made with precision to cover the IHS effectively and put optimal pressure on the die area.

This new water block kept the name "Velocity" because it retained the ability to be responsive and agile in the world of liquid cooling. Embedded in the Velocity² is a next-generation EK CPU water block cooling engine that is socket-specific. A combination of mounting pressure and cold plate geometry, tailored for the IHS and die layout of Intel LGA 1700 socket processors, is used to achieve low hydraulic flow restriction and high performance. Thе lathe-turned cold plate is made with precision to cover the IHS effectively and put optimal pressure on the die area.