Friday, April 30th 2021

UMC Investing $3.6 billion on 28 nm Manufacturing Capabilities Amidst Worldwide Semiconductor Shortages

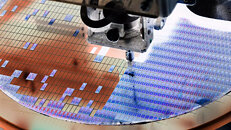

UMC has announced plans to invest $3.6 billion in increasing output from its 28 nm manufacturing facilities. This move comes amidst a global semiconductor shortage, and isn't the first time a semiconductor manufacturer "dust off" their older manufacturing processes as a way to remove pressure from more modern silicon manufacturing capabilities. In this case, UMC will be increasing manufacturing output from its 300 mm Fab 12A facility in Tainan, Taiwan.

UMC has entered agreements with some of its clients, who will be paying upfront for expected chip rollout in the future. In exchange, clients will get the benefits of preset pricing (thus avoiding any potential increases arising from increased demand or general price fluctuation), as well as UMC's assurance of certain manufacturing volume allocation towards their needs. Fab 12A currently manufactures 90,000 300 mm wafers per month (wpm). An additional 10,000 wpm is being installed this year and phase six will add another 27,500 wpm to the mix. The mature 28 nm tools will be installed in floors that already feature support for future tooling upgrades to 14 nm. UMC expects to hire around 1,000 additional employees as part of this expansion effort.

Source:

TechSpot

UMC has entered agreements with some of its clients, who will be paying upfront for expected chip rollout in the future. In exchange, clients will get the benefits of preset pricing (thus avoiding any potential increases arising from increased demand or general price fluctuation), as well as UMC's assurance of certain manufacturing volume allocation towards their needs. Fab 12A currently manufactures 90,000 300 mm wafers per month (wpm). An additional 10,000 wpm is being installed this year and phase six will add another 27,500 wpm to the mix. The mature 28 nm tools will be installed in floors that already feature support for future tooling upgrades to 14 nm. UMC expects to hire around 1,000 additional employees as part of this expansion effort.

26 Comments on UMC Investing $3.6 billion on 28 nm Manufacturing Capabilities Amidst Worldwide Semiconductor Shortages

Also, it's not clear whether the current manufacturing can run uninterrupted while the new equipment is being installed or not. If not ... ouch.

* Licensed from UMC

** 500W PL2.

www.taiwannews.com.tw/en/news/4190159

Right before this announcement they bought lots of fab equipment from Samsung in order to manufacture CMOS sensors for Samsung.

I'm sure it's not just "projections" that drive this expansion. They are most likely booked to the brim already. 28nm is still widely used everywhere: not just automotive, industrial, embedded/IoT etc., but also parts for consumer electronics which you never think about, like OLED & LCD drivers, touch screen controllers, PMICs, SuperI/O chips, memory, flash storage and lots of other stuff.