5

5

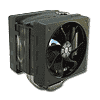

Cooler Master V6GT Review

Assembly & Installation »A Closer Look

Fully assembled the V6GT looks really aggressive. Dual 120 mm fans housed in decorative black shrouds not only make this unit look good but add to performance as well. With its all black color scheme the V6GT should nicely compliment any machine you choose to utilize it in.

Cooler Master utilizes six copper heat-pipes in a "Double V" pattern which helps dissipate heat quicker by allowing more of the heat-pipes surface area to be exposed to the air flowing through the cooler itself. Both the heat-pipes and the cooler's base are made from copper and the entire cooler is nickel plated to resist oxidation, which also makes it quite attractive as well.

While the base of the V6GT is not polished to mirror finish, it is still quite reflective. The razor test assures us that Cooler Master has taken the necessary steps to ensure the base of the cooler is near perfectly flat. Exactly what we want to see on a good high quality cooler.

Cooler Master utilizes densely stacked asymmetrical tilted aluminum fins which aid in cooling performance. The 5° tilt creates more air turbulance compared to a typical fin design causing air to circulate through the cooler in a manner which removes more heat. On top of the cooler you will find an "Engine oil cap" which controls the LED strip with color changing function. The fancy LED strip can be set to one of three selectable colors, red, blue, or purple but you can also choose not to have the strip illuminated. It is powered by a standard four pin Molex connector.

Included with the cooler are a pair of "Evolutionary wave blade" fans which provide up to 93 CFM per fan. Another feature of these fans is the DynaLoop Bearing which is a self-lubricating bearing mechanism that decreases oil-loss commonly seen on sleeve bearing fans. This means low noise operation as well as long expected lifetime operation before failure. Cooler Master has also included a four pin Y-Splitter to ensure both fans can be PWM controlled by the motherboard. While it is common to see Y-Splitters included with coolers, this is the first I have seen with the fourth wire for PWM control, a good feature for sure.

Apr 8th, 2025 05:29 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- is it worth using ssd with usb2? (13)

- Is RX 9070 VRAM temperature regular value or hotspot? (330)

- RX 9000 series GPU Owners Club (238)

- 5070 cards available below £550 in in the UK (76)

- 9070XT or 7900XT or 7900XTX (130)

- The easiest way to connect the BOOTSEL test metal terminal and the GND terminal.... (2)

- gpu heirarchy/performance/benchmarks- whos lying? (67)

- Sapphire NITRO+ RX 5700 XT BE original BIOS request (11)

- No idea how many watts this USB-C port will supply? (10)

- The coffee and tea drinkers club. (250)

Popular Reviews

- The Last Of Us Part 2 Performance Benchmark Review - 30 GPUs Compared

- UPERFECT UStation Delta Max Review - Two Screens In One

- PowerColor Radeon RX 9070 Hellhound Review

- ASUS Prime X870-P Wi-Fi Review

- Upcoming Hardware Launches 2025 (Updated Apr 2025)

- MCHOSE L7 Pro Review

- Sapphire Radeon RX 9070 XT Pulse Review

- Corsair RM750x Shift 750 W Review

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- DDR5 CUDIMM Explained & Benched - The New Memory Standard

Controversial News Posts

- NVIDIA GeForce RTX 5060 Ti 16 GB SKU Likely Launching at $499, According to Supply Chain Leak (161)

- MSI Doesn't Plan Radeon RX 9000 Series GPUs, Skips AMD RDNA 4 Generation Entirely (146)

- Microsoft Introduces Copilot for Gaming (124)

- AMD Radeon RX 9070 XT Reportedly Outperforms RTX 5080 Through Undervolting (119)

- NVIDIA Reportedly Prepares GeForce RTX 5060 and RTX 5060 Ti Unveil Tomorrow (115)

- Over 200,000 Sold Radeon RX 9070 and RX 9070 XT GPUs? AMD Says No Number was Given (100)

- NVIDIA GeForce RTX 5050, RTX 5060, and RTX 5060 Ti Specifications Leak (97)

- Nintendo Switch 2 Launches June 5 at $449.99 with New Hardware and Games (92)