31

31

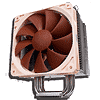

Noctua NH-U12P Heatsink Review

Installation Cont. »Installation

To start the installation for the Noctua NH-U12P, two plates and four screws are needed from the common hardware bag. The screws need to pass through the base plate from the bottom and get screwed into the two plates on each side. The included L-shaped screwdriver can be used, or any another one from the user's toolbox.

For LGA 775 installation, the hardware from that bag is required. This includes a backplate, two brackets, four felt washers, four small screws, two larger screws and two springs. The backplate has a square of double-sided tape on it that can be used to attach it to the backside of the motherboard after lining up the holes correctly.

The next step is to install the two brackets on the sides of the CPU socket. The first step is to place the four felt washers over the holes on the motherboard. Next the brackets need to be set in place. Note that these brackets are being installed on the left and right sides of the socket so that the fan will blow toward the rear of the case. If the fan is needed to blow up toward an exhaust fan or PSU, then the brackets should be installed on the top and bottom of the socket. Insert the four small screws through these brackets and into the backplate, then tighten them completely.

Since many motherboard manufacturers often place components around the CPU socket, this area was inspected for possible incompatibilities. I was mostly worried about the hole in the rear bracket (next to the MOSFET heatsink) that was right over one of the coils, and I wanted to make sure that there would not be any problems when the screw was inserted.

Next the CPU and heatsink were cleaned and thermal compound was applied according to the manufacturer's directions. In this case, the included Noctua NT-H1 was used, as it has proven itself to be an excellent compound that is ready without a long burn-in time. A small 4-5mm ball was placed in the center of the CPU's heatspreader, and the NH-U12P was placed on top and twisted a few times to force the compound to spread out.

The two longer screws need to be inserted through the springs and used to attach the heatsink to the brackets. The screws should be tightened completely and they will bottom out when the shoulder hits the bracket. When this occurred, the one coil below the bracket was inspected for contact. Fortunately, there was nothing to worry about.

Jan 9th, 2025 17:15 EST

change timezone

Latest GPU Drivers

New Forum Posts

- Flashing 4090 MSI Ventus 3x E OC (4)

- Are people planning an upgrade? (143)

- Power supply or motherboard (20)

- Looking for 10" android tablet (2)

- thermal limiting on i5 8265u, pls HELP (4)

- Nvidia drivers versus AMD drivers on Wayland (36)

- What's your latest tech purchase? (22826)

- 12VHPWR ATX3.0 PCI-E 5.0 Power Modular Adapter 600W will be enough for RTX 5090? (38)

- What are you playing? (22550)

- All RTX 5090s only have 1x 16-pin connector (43)

Popular Reviews

- ASUS ROG Strix B850-F Gaming WiFi Review

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

- DDR5 Thermal Testing & Analysis

- HEDDphone TWO GT Air Motion Transformer Headphones Review

- Royal Kludge S85 TKL Wireless Mechanical Keyboard Review

- GPU Test System Update for 2025

- Call of Duty: Black Ops 6 Performance Benchmark Review - AMD FTW

- Upcoming Hardware Launches 2024 (Updated Nov 2024)

- Intel Arc B580 Review - Excellent Value

- SCYROX V8 Review

Controversial News Posts

- NVIDIA 2025 International CES Keynote: Liveblog (447)

- AMD Debuts Radeon RX 9070 XT and RX 9070 Powered by RDNA 4, and FSR 4 (339)

- NVIDIA GeForce RTX 5090 Features 575 W TDP, RTX 5080 Carries 360 W TDP (210)

- AMD Radeon RX 9070 XT Alleged Benchmark Leaks, Underwhelming Performance (204)

- Potential RTX 5090 and RTX 5080 Pricing in China Leaks (173)

- 32 GB NVIDIA RTX 5090 To Lead the Charge As 5060 Ti Gets 16 GB Upgrade and 5060 Still Stuck With Last-Gen VRAM Spec (173)

- AMD Radeon RX 9070 XT Boosts up to 3.10 GHz, Board Power Can Reach up to 330W (167)

- NVIDIA GeForce RTX 5070 Ti Leak Tips More VRAM, Cores, and Power Draw (161)