23

23

Super Flower Leadex Platinum 2000 W Review

Load Regulation, Hold-up Time & Inrush Current »A Look Inside & Component Analysis

Before reading this page, we strongly suggest a look at this article, which will help you understand the internal components of a PSU much better. Our main tool for the disassembly of the PSU is a Thermaltronics TMT-9000S soldering and rework station. It is of extreme quality and is equipped with a matching de-soldering gun. With such equipment in hand, breaking apart every PSU is like a walk in the park!| Super Flower SF-2000F14HP Parts Description | |

|---|---|

| Primary Side | |

| Transient Filter | 6x Y caps, 2x X caps, 2x CM chokes, 1x MOV |

| Bridge Rectifier(s) | Bridgeless Design - 1x US30K80RΒ & 8x Infineon MOSFETs |

| Inrush Current Protection | NTC Thermistor & Relay |

| APFC Mosfets | 8x Infineon MOSFETs |

| APFC Boost Diode | 4x CREE C3D08060G |

| Hold-up Cap(s) | 4x Nippon Chemi-Con (400 V, 3x 390 uF & 1x 470 uF; 1640 uF combined, 105°C, KMW) |

| Main Switchers | 4x IPP60R099CP |

| APFC Controller | SF29603 |

| Switching Controller | SFAA9013 |

| Topology | Primary side: Bridgeless PFC & Full-Bridge LLC & Resonant Converter Secondary side: Synchronous Rectification & DC-DC converters |

| Secondary Side | |

| +12V | 16x Infineon BSC027N04LS |

| 5V & 3.3V | DC-DC Converters: 8x Infineon IPD060N03Β fets |

| Filtering Capacitors | Electrolytics: Chemi-Con, 105 °C, KY & KRG Polymers: Chemi-Con |

| Supervisor IC | AA9013 (probably) & LM324ADG |

| Fan Model | Globe Fan RL4Z-B1402512EH (140 mm, 12 V, 0.6 A, 2000 RPM, 153.47 CFM, 39.5 dB(A), 70,000-hour MTBF) |

| 5VSB Circuit | |

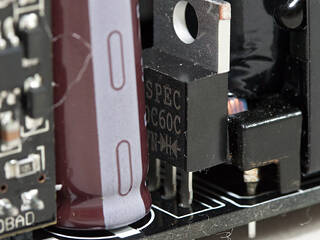

| Rectifying Diode | Mospec S10C60C |

| Standby PWM Controller | 29604 |

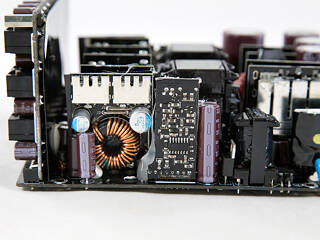

This platform is the same as in Super Flower's 1.6 kW Leadex Titanium PSU or the similarly strong EVGA G2 and P2 units. Its cutting-edge design not only enables it to achieve such a high capacity as it is also incredibly efficienct. Super Flower says the unit to meet 80 Plus Platinum requirements with 230 VAC input (92% efficiency with 20% load, 94% with 50% load, and 90% at full load). With the SF-2000F14HP, AC rectification takes part inside the APFC converter instead of separate bridge rectifiers, which leads to a significant efficiency boost. The primary side also uses a full-bridge topology, while the secondary side makes use of a synchronous design with a huge number of fets that handle the +12V rail. As expected, DC-DC converters generate the minor rails. In short, the unit uses a bridgeless PFC and a full-bridge topology with an LLC resonant converter, with a synchronous design and DC-DC converters in the secondary side.

Behind the AC receptacle is a small PCB that doesn't include any of the transient filer's components. The latter are installed on the main PCB and include three pairs of Y caps, a pair of X caps, an MOV, and two CM chokes, which also completes the transient filter.

Here is a single bridge rectifier, a US30K80R. It is only put to use at very light loads or in standby mode.

The APFC converter consists of two fully packed daughter-boards and two large coils. Each of the boards holds eight fets that are protected against EMI by metal shields and four CREE C3D08060G boost diodes. These boards not only bring the power factor close to unity, but also fully rectify the incoming alternating current (AC) voltage. Four parallel Nippon Chemi-Cons are used as bulk caps (400 V, 3x 390 uF & 1x 470 uF or 1640 uF combined, 105°C, KMW), and we suspect that their capacity isn't enough to keep this PSU's maximum power output for at least 16 ms once the mains power is removed.

The PFC controller, a proprietary IC codenamed SF29603, is on this EMI shielded board.

A pretty large NTC thermistor protects the unit against large inrush currents, and it has its own relay to cut it off the circuit as required.

Two boards hold all the main switchers, four Infineon IPP60R099CPs arranged into a full-bridge topology. An LLC converter is also used to boost efficiency.

Four vertical PCBs in the secondary side house all the mosfets that regulate the +12V rail. In total, 16 Infineon BSC027N04LS fets have been assigned to the task, and our tests prove that they can provide much more than 2 kW should the need arise.

Two DC-DC converters handle the minor rails. Each converter uses four Infineon IPD060N03 fets. Right next to one of these boards is the PCB that houses the fan's control circuit and a Mospec S10C60C SBR that generates the 5VSB rail. The same PCB also houses an LM324ADG.

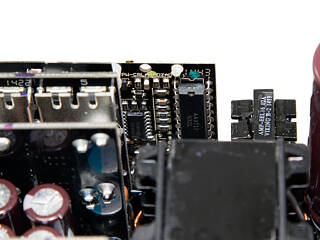

The standby PWM controller has "29604" written on it, which didn't prove terribly useful in identifying it.

All filtering capacitors in the secondary side, electrolytic and polymer, are by Nippon Chemi-Con, so they are of very high quality.

On the other side of the daughter-board depicted above is the resonant controller, an AA9013 IC for which there is no available information. There is also a LM324ADG IC on the same board.

On the primary side of the modular PCB are a large number of polymer and electrolytic caps. These caps are used for ripple-filtering purposes. All are provided by Chemi-Con, so there is no doubt about their high quality.

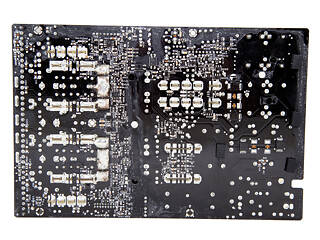

Soldering quality isn't the best we have seen from Super Flower. The manufacturing line probably needs some tuning. We didn't like the finish on the PCB's solder side, and there were also some sloppy solder jobs that could have been avoided. However, our tests show that the soldering quality doesn't seem to affect performance.

The cooling fan is the same as in all high-end Super Flower units. It is by Globe Fan, and its model number is RL4Z-B1402512EH (140 mm, 12 V, 0.6 A, 2000 RPM, 153.47 CFM, 39.5 dBA, 70.000 MTBF). This fan is equipped with double ball-bearings for increased longevity, and the fan's profile isn't what we would call relaxed, which comes as no surprise since this PSU is a real power house. The PSU also doesn't feature a semi-passive mode, but contrary to other SF implementations, its fan-control circuit comes with many speed profiles that will, depending on ambient conditions, vary fan speed a lot as there are more than three or four available modes it switches between.

Mar 10th, 2025 16:44 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- DLSS as antialiasing? (21)

- Maxsun RX580 graphics card crashes (27)

- Fix for Vram frequency always at maximum (0)

- Please I need help with the poor performance that my PC is giving me (28)

- Company of Heroes 3 (5)

- The TPU Darkroom - Digital SLR and Photography Club (4071)

- A Final Fantasy IX Reminiscence - My love letter and homage to one of the best stories ever told (72)

- Gaming PC instabiliity (20)

- Msi 5090 DOA? (27)

- 3D Printer Club (447)

Popular Reviews

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- XFX Radeon RX 9070 XT Mercury OC Magnetic Air Review

- ASUS Radeon RX 9070 TUF OC Review

- MSI MAG B850 Tomahawk Max Wi-Fi Review

- NVIDIA GeForce RTX 5080 Founders Edition Review

- NVIDIA GeForce RTX 5070 Founders Edition Review

- Corsair Vengeance RGB CUDIMM DDR5-8800 48 GB CL42 Review

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

- ASUS GeForce RTX 5070 Ti TUF OC Review

- MSI GeForce RTX 5070 Ti Gaming Trio OC+ Review

Controversial News Posts

- NVIDIA GeForce RTX 50 Cards Spotted with Missing ROPs, NVIDIA Confirms the Issue, Multiple Vendors Affected (513)

- AMD Plans Aggressive Price Competition with Radeon RX 9000 Series (277)

- AMD Radeon RX 9070 and 9070 XT Listed On Amazon - One Buyer Snags a Unit (261)

- AMD RDNA 4 and Radeon RX 9070 Series Unveiled: $549 & $599 (260)

- AMD Mentions Sub-$700 Pricing for Radeon RX 9070 GPU Series, Looks Like NV Minus $50 Again (248)

- NVIDIA Investigates GeForce RTX 50 Series "Blackwell" Black Screen and BSOD Issues (244)

- AMD Radeon RX 9070 and 9070 XT Official Performance Metrics Leaked, +42% 4K Performance Over Radeon RX 7900 GRE (195)

- AMD Radeon RX 9070-series Pricing Leaks Courtesy of MicroCenter (158)