Tuesday, June 14th 2011

EKWB Halts Nickel-Plated Water Block Production

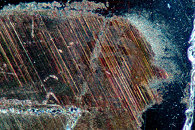

Water-cooling major EK Waterblocks (EKWB) halted the production of nickel-plated copper water blocks. The company received several complaints from users about the nickel plating to be of substandard quality, and corroding away much faster. Nickel plating itself is supposed to work as a corrosion-resistant coating over copper. Nickel plating gives the surface of the block a chrome-like lustrous shine. EKWB, after conducting its own tests, blamed silver coils and copper sulphate additives, anti-algae agents used in public water supply. A weak defense, considering people use distilled water (battery water) in their loops, or coolants that are formulated to be less corrosive than tap water on metallic parts of the loop.A RRTech forum member conducted a wide range of tests including microscopic imaging of a water block, revealing what he alleges to be substandard quality of nickel plating, rather than corrosion caused by bad coolant. Meanwhile, EKWB halted production and sales of nickel-plated copper water blocks.

In its latest statement, EKWB says: "As EK is looking for lasting solution for nickel plating issue (concerning corrosion because of silver coils and copper sulphate additive) we decided to halt sales of nickel plated products till solution is found and tested. Our resellers were advised to halt sales too. We cannot put users into position, that we replace products and corrosion starts again on new product. Hopefully we will find an answer and tested solution in short while. We will update you as soon as we have any news. However, If customer insists on buying EK nickel block, we offer a customer full 24 month warranty on material, manufacturing and corrosion."

More gory pictures of failing water blocks at the source.

Sources:

RRTech, Bit-Tech

In its latest statement, EKWB says: "As EK is looking for lasting solution for nickel plating issue (concerning corrosion because of silver coils and copper sulphate additive) we decided to halt sales of nickel plated products till solution is found and tested. Our resellers were advised to halt sales too. We cannot put users into position, that we replace products and corrosion starts again on new product. Hopefully we will find an answer and tested solution in short while. We will update you as soon as we have any news. However, If customer insists on buying EK nickel block, we offer a customer full 24 month warranty on material, manufacturing and corrosion."

More gory pictures of failing water blocks at the source.

62 Comments on EKWB Halts Nickel-Plated Water Block Production

Update: My blocks looked great. Nice and Bright, nothing wrong with them. I did find a couple several nozzles that looked pretty rusted out and that must have been the cause. I replaced them with better quality ones and hope that is all that was wrong. Man, this thread had me worried. LOL.

Either way, the people are freaking out about what seems like really bad corrosion to the blocks that never happen under normal usage.

specific thread on trade practices right here

www.realredraider.com/vbulletin/showthread.php?t=48071

posted on june 7th and i personally have not seen that info posted anywhere else,

oddly enough rrtech has been getting a lot of traffic from slovenia:)

Lol.. Ek is in constant look at RRtech.. Nice.. Oh, well.. RRtech showed where it's really at..

joined this forum in 2004 and that post above was my 1st:laugh:

cya again in 7 years or so.

Anyways, reading through a couple threads over at XS I found this post to be very interesting:

www.xtremesystems.org/forums/showthread.php?271881-Official-EK-statement-Nickel-Plating-Issues&p=4873956&viewfull=1#post4873956

also, my comment about warranty was how it has been for weeks, I only read here and on ocau today that they're extending the RMA period. It's no suprise though, since if they didn't, they'd be looking at a law suit.

the rest of what i said stands. :shadedshu

And thank you Cold storm for spreading the news.

If we ran mineral based hydraulic fluids like 5606 we might be able to solve that corrosion issue. It's also good to run in high pressure systems. I wonder if it could be run in current loops and if it transfers heat like the automotive coolant we are using in many loops today. Of course it couldn't work as well as the distilled water method but its anti corrosion properties would help if corrosion starts becoming a bigger issue.

You would think EK would have tested these nickel coatings(or plating) before selling them out on the market and having them corrode.