Monday, March 26th 2007

IBM Improves CPU Cooling

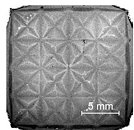

New research by Big Blue could see CPUs running up to 40% cooler in the near future, without needing prices to rocket. In a paper released at the IEEE Semi-Therm conference, IBM published ideas designed to make thermal paste more efficient, therefore allowing for an improved cooling capacity leading to cooler processors. According to IBM, current thermal paste techniques can lead to 40% of heat given off by the CPU being absorbed by the particles in the paste, largely caused by the fact that the particles don't spread evenly, leading to the "Magic Cross" shown in the image below and to the left. IBM's new technology involves integrating micro-meter length trenches into the copper cap that sits above the CPU core (below on the right), which will allow thermal paste to be more evenly distributed and will lead to a third less thermal paste being required, as well as halving the pressure required to fit a CPU cooler. IBM still needs to finalise the research, but this relatively in-expensive method could be integrated into new CPUs and coolers before too long. For more detailed information you can read IBM's press release.

Source:

ars technica

15 Comments on IBM Improves CPU Cooling

IBM is obviously huge in the server market, and always selling research and development.

DBH: this is a press release, the earlier one was research time news.

Edit: you must be meaning this from October (can't find anything newer). Admittedly this is the same story but it has been developed a bit more and IBM has given more details this time, so I'll class it as an update :D

This is a key quote from IBM:Lapping the metal cap (top) and the heatsink (bottom) is still a good idea.