Qualcomm Completes Acquisition of NUVIA

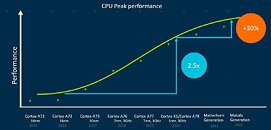

Qualcomm Incorporated (NASDAQ: QCOM) today announced that its subsidiary, Qualcomm Technologies, Inc., has completed its acquisition of the world-class CPU and technology design company, NUVIA for $1.4 billion before working capital and other adjustments.

"The world-class NUVIA team enhances our CPU roadmap, extending Qualcomm's leading technology position with the Windows, Android and Chrome ecosystems," said Cristiano Amon, President and CEO-Elect, Qualcomm Incorporated. "The broad support of this acquisition from across industries validates the opportunity we have to provide differentiated products with leading CPU performance and power efficiency, as on-demand computing increases in the 5G era."

"The world-class NUVIA team enhances our CPU roadmap, extending Qualcomm's leading technology position with the Windows, Android and Chrome ecosystems," said Cristiano Amon, President and CEO-Elect, Qualcomm Incorporated. "The broad support of this acquisition from across industries validates the opportunity we have to provide differentiated products with leading CPU performance and power efficiency, as on-demand computing increases in the 5G era."