5

5

Cooler Master G550M 550 W Review

Voltage Regulation, Hold-up Time & Inrush Current »A Look Inside & Component Analysis

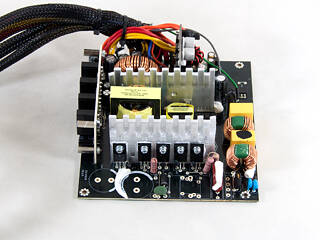

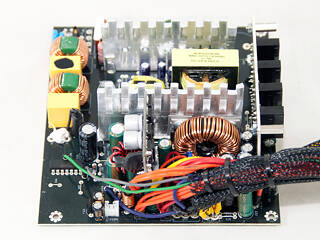

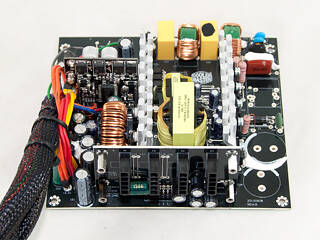

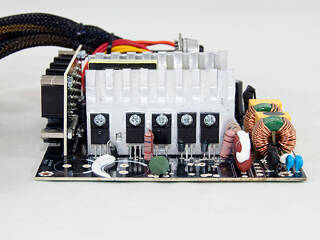

Before reading this page, we strongly suggest a look at this article, which will help you understand the internal components of a PSU much better. Our main tool for the disassembly of the PSU is a Thermaltronics TMT-9000S soldering and rework station. It is of extreme quality and is equipped with a matching de-soldering gun. With such equipment in hand, breaking apart every PSU is like a walk in the park!This unit is made by Channel Well Technology, an OEM with a lot of experience and good overall products. The platform isn't cutting edge since Bronze efficiency can nowadays easily be achieved without any exotic components. The secondary side utilizes VRMs (Voltage Regulation Modules) for the generation of the minor rails, and the +12V rail is rectified by active components. Also, the PCB is small and not densely populated since the PSU's small capacity doesn't take many, or bulky, components.

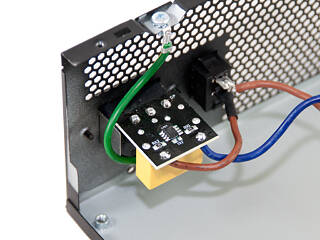

The transient filter starts at the AC receptacle with one X and two Y caps. We also find a small IC which isolates the bleeding resistor of the C cap once the PSU starts—redistricting energy losses—on the solder side of the small PCB that holds the aforementioned components. All other components of the transient/EMI filter are located on the main PCB and consist of two X and two Y caps, two CM chokes, and an MOV.

The bridge rectifier with model number GBU1006 is soldered to a small dedicated heatsink.

The APFC converter uses two SGF160N60W3 fets and a Power Integrations LXA08FP600 boost diode. The bulk cap is provided by Panasonic (400 V, 470 µF, 85°C), and its capacity looks alright for the needs of this unit; however, the NTC thermistor that protects against large inrush currents is rather small.

A couple of SGF190N60SJ fets are used as main switchers.

The standby PWM controller is a TNY177PN IC.

A synchronous design is used for the rectification of the +12V rail on the secondary side, and three SG65N0PFR fets handle this rail. The filtering caps here are mostly CapXon electrolytics, but we also found a single Jun Fu (not Kung Fu!) cap. CM apparently tried to save on cost here by going with such mediocre caps, which we didn't like, but it will ultimately be their problem if something goes wrong given they cover this product with a pretty long warranty.

Both VRMs generating the minor rails are housed on the same PCB. The common PWM controller is an APW7159 IC, and two pairs of M3004D and M3006D fets are used along with it.

We find another Jun Fu cap and several CapXon (also known as CrapXon) ones on the front of the modular PCB.

The supervisor IC is soldered to the main PCB and is a Sitronix ST9S429-PG14; it has two OCP +12V channels and doesn't include OTP (Over Temperature Protection), so the latter must be implemented via another way.

Soldering quality is decent overall and we spotted the combo PFC/PWM controller—it is mostly found on older designs or lower efficiency PSUs, like the Champion CM6800TX.

The cooling fan is provided by Yate Loon, and its model number is D12BH-12 (120 mm, 12 V, 0.3 A, 2300 RPM, 89 CFM, 41 dBA). It uses ball bearings and is pretty strong for a 550 W PSU, even for a Bronze efficiency one. Its fan profile is thankfully pretty relaxed, so it will spin at very low speeds for very little noise at normal loads and temperatures.

Jul 12th, 2025 01:14 CDT

change timezone

Latest GPU Drivers

New Forum Posts

- Will you buy a RTX 5090? (641)

- 'NVIDIA App' not usable offline? (8)

- Can you guess Which game it is? (222)

- What are you playing? (23920)

- RX 9070 XT freezing/locking up only on desktop, anyone else? (43)

- NVIDIA RTX PRO 6000 Workstation Runs Much Hotter Than 5090 FE (22)

- Quick charging your USB devicesUSB 3.2 Gen 2x2 Type-C® front-panel. (1)

- GTX 1050 GPU Owners Club (12)

- ASUS ProArt GeForce RTX 4060 Ti OC Edition 16GB GDDR6 Gaming - nvflash64 VBIOS mismatch (2)

- No offense, here are some things that bother me about your understanding of fans. (33)

Popular Reviews

- Fractal Design Epoch RGB TG Review

- Corsair FRAME 5000D RS Review

- Lexar NM1090 Pro 4 TB Review

- NVIDIA GeForce RTX 5050 8 GB Review

- NZXT N9 X870E Review

- Sapphire Radeon RX 9060 XT Pulse OC 16 GB Review - An Excellent Choice

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

- Upcoming Hardware Launches 2025 (Updated May 2025)

- Our Visit to the Hunter Super Computer

- Chieftec Iceberg 360 Review

TPU on YouTube

Controversial News Posts

- Intel's Core Ultra 7 265K and 265KF CPUs Dip Below $250 (288)

- Some Intel Nova Lake CPUs Rumored to Challenge AMD's 3D V-Cache in Desktop Gaming (140)

- AMD Radeon RX 9070 XT Gains 9% Performance at 1440p with Latest Driver, Beats RTX 5070 Ti (131)

- NVIDIA Launches GeForce RTX 5050 for Desktops and Laptops, Starts at $249 (119)

- NVIDIA GeForce RTX 5080 SUPER Could Feature 24 GB Memory, Increased Power Limits (115)

- Microsoft Partners with AMD for Next-gen Xbox Hardware (105)

- Intel "Nova Lake‑S" Series: Seven SKUs, Up to 52 Cores and 150 W TDP (100)

- NVIDIA DLSS Transformer Cuts VRAM Usage by 20% (97)