Marvell Announces Industry's First 112G 5nm SerDes Solution for Scaling Cloud Data Center Infrastructure

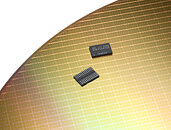

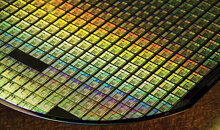

Marvell today unveiled the industry's first 112G 5 nm SerDes solution that has been validated in hardware. The DSP-based SerDes boasts industry-leading performance, power and area, helping to propel 112G as the interconnect of choice for next generation 5G, enterprise, and cloud data center infrastructure. Marvell has recently secured a new custom ASIC design win customer that will embed this new IP to build next generation top-of-rack (ToR) and spine switches for leading hyperscale data centers around the world. The Marvell 5 nm SerDes solution doubles the bandwidth of current systems based on 56G while enabling the deployment of 112G I/Os in many exciting new applications, including network and data center switching, network traffic management, machine learning training and inference, and application-specific accelerators.

Today's news, which comes on the heels of the company's announcement with TSMC of its 5 nm portfolio, further strengthens Marvell's leading data infrastructure offerings in the industry's most advanced process geometry. The 112G 5 nm SerDes solution is part of Marvell's industry-leading IP portfolio that addresses the full spectrum of infrastructure requirements and includes processor subsystems, encryption engines, system-on-chip fabrics, chip-to-chip interconnects, and a variety of physical layer interfaces.

Today's news, which comes on the heels of the company's announcement with TSMC of its 5 nm portfolio, further strengthens Marvell's leading data infrastructure offerings in the industry's most advanced process geometry. The 112G 5 nm SerDes solution is part of Marvell's industry-leading IP portfolio that addresses the full spectrum of infrastructure requirements and includes processor subsystems, encryption engines, system-on-chip fabrics, chip-to-chip interconnects, and a variety of physical layer interfaces.