Apr 1st, 2025 12:38 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- Rare GPUs / Unreleased GPUs (2049)

- best ram to buy for my usage and system specs? (4)

- Msi Vector 16HX Undervolt (8)

- WCG Daily Numbers (12822)

- RX 9000 series GPU Owners Club (93)

- Opened Thaiphoon then crash! (0)

- Folding Pie and Milestones!! (9454)

- Help me pick a UPS (14)

- AMD RX 9070 XT & RX 9070 non-XT thread (OC, undervolt, benchmarks, ...) (76)

- What is the latest game you finished or 100% (16)

Popular Reviews

- DDR5 CUDIMM Explained & Benched - The New Memory Standard

- Sapphire Radeon RX 9070 XT Pulse Review

- ASRock Phantom Gaming B850 Riptide Wi-Fi Review - Amazing Price/Performance

- Palit GeForce RTX 5070 GamingPro OC Review

- SilverStone Lucid 04 Review

- Samsung 9100 Pro 2 TB Review - The Best Gen 5 SSD

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- Enermax REVOLUTION D.F. 12 850 W Review

- Assassin's Creed Shadows Performance Benchmark Review - 30 GPUs Compared

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

Controversial News Posts

- MSI Doesn't Plan Radeon RX 9000 Series GPUs, Skips AMD RDNA 4 Generation Entirely (142)

- Microsoft Introduces Copilot for Gaming (124)

- AMD Radeon RX 9070 XT Reportedly Outperforms RTX 5080 Through Undervolting (119)

- NVIDIA Reportedly Prepares GeForce RTX 5060 and RTX 5060 Ti Unveil Tomorrow (115)

- Over 200,000 Sold Radeon RX 9070 and RX 9070 XT GPUs? AMD Says No Number was Given (100)

- NVIDIA GeForce RTX 5050, RTX 5060, and RTX 5060 Ti Specifications Leak (96)

- Retailers Anticipate Increased Radeon RX 9070 Series Prices, After Initial Shipments of "MSRP" Models (90)

- China Develops Domestic EUV Tool, ASML Monopoly in Trouble (88)

Friday, April 13th 2018

Noctua Tease Their Impending Sterrox-Made, A-Series, NF-A12x25 Fan

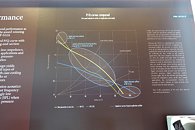

Noctua has started teasing for the upcoming launch of their latest-generation fan design, based in more than four years of development on new materials that shed some of PBT's known weaknesses. The new fan line was first announced at Computex 2017, and at that time, the development resources poured into the project were well over more than four years and 200 test designs (we already wrote an exhaustive piece on these new fans, if you want to know more or need a refresher).

Noctua says these new fans will be twice as good as their existing ones; the company showed at Computex 2017 how a single A-series fan achieved identical temperatures to a setup which used two NF-F12 fans on the same processor, workload, and heatsink. And you thought the NF-F12 were good already, right? There's no actual release date for now, but there's a teaser image of the packaging doing the rounds already - and if that's that far along finished, then we're certainly not that far away from release. Here's hoping pricing will be competitive - but perhaps it needn't be, considering the expected performance - and the fact that Sterrox, the compound used in their manufacturing, is four times more expensive than common PBT.

Source:

Noctua's Instagram

Noctua says these new fans will be twice as good as their existing ones; the company showed at Computex 2017 how a single A-series fan achieved identical temperatures to a setup which used two NF-F12 fans on the same processor, workload, and heatsink. And you thought the NF-F12 were good already, right? There's no actual release date for now, but there's a teaser image of the packaging doing the rounds already - and if that's that far along finished, then we're certainly not that far away from release. Here's hoping pricing will be competitive - but perhaps it needn't be, considering the expected performance - and the fact that Sterrox, the compound used in their manufacturing, is four times more expensive than common PBT.

Apr 1st, 2025 12:38 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- Rare GPUs / Unreleased GPUs (2049)

- best ram to buy for my usage and system specs? (4)

- Msi Vector 16HX Undervolt (8)

- WCG Daily Numbers (12822)

- RX 9000 series GPU Owners Club (93)

- Opened Thaiphoon then crash! (0)

- Folding Pie and Milestones!! (9454)

- Help me pick a UPS (14)

- AMD RX 9070 XT & RX 9070 non-XT thread (OC, undervolt, benchmarks, ...) (76)

- What is the latest game you finished or 100% (16)

Popular Reviews

- DDR5 CUDIMM Explained & Benched - The New Memory Standard

- Sapphire Radeon RX 9070 XT Pulse Review

- ASRock Phantom Gaming B850 Riptide Wi-Fi Review - Amazing Price/Performance

- Palit GeForce RTX 5070 GamingPro OC Review

- SilverStone Lucid 04 Review

- Samsung 9100 Pro 2 TB Review - The Best Gen 5 SSD

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- Enermax REVOLUTION D.F. 12 850 W Review

- Assassin's Creed Shadows Performance Benchmark Review - 30 GPUs Compared

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

Controversial News Posts

- MSI Doesn't Plan Radeon RX 9000 Series GPUs, Skips AMD RDNA 4 Generation Entirely (142)

- Microsoft Introduces Copilot for Gaming (124)

- AMD Radeon RX 9070 XT Reportedly Outperforms RTX 5080 Through Undervolting (119)

- NVIDIA Reportedly Prepares GeForce RTX 5060 and RTX 5060 Ti Unveil Tomorrow (115)

- Over 200,000 Sold Radeon RX 9070 and RX 9070 XT GPUs? AMD Says No Number was Given (100)

- NVIDIA GeForce RTX 5050, RTX 5060, and RTX 5060 Ti Specifications Leak (96)

- Retailers Anticipate Increased Radeon RX 9070 Series Prices, After Initial Shipments of "MSRP" Models (90)

- China Develops Domestic EUV Tool, ASML Monopoly in Trouble (88)

27 Comments on Noctua Tease Their Impending Sterrox-Made, A-Series, NF-A12x25 Fan

It's the use of a 4 pole motor. You're right that using more poles can reduce vibration, but it's not because 4 pole motors are inherently bad. It's to do with the switching of the poles as the motor spins.

To reduce vibration and make rotation as consistent as possible, you can either switch the poles at the appropriate, accurate point in the rotation to drive the fan (Thus meaning the motor can apply the same level of torque at all times, rather than having to spin the fan fractionally back up to speed each time the pole switches), or you can use more poles so that the accuracy of the switching can be reduced. Neither approach is better - the more poles approach is easier to design but has a higher material cost, the traditional 4 pole approach CAN introduce vibration (because the torque of the motor must be applied very precisely), but it's real drawback is that the manufacturing tolerances must be better if you intend to avoid vibration - both approaches can and do, produce fans with no vibration issues at all - the 4 pole approach is by far the more common however, and the gentle typhoons, scythes old s-flex series, and almost any other case fan you've ever owned is probably a 4 pole. Proof in relation to the GT is right here - thermalbench.com/2017/05/25/darkside-gentle-typhoon-1150-rpm-120-mm-fan/2/

The only 6 pole motors I know of are the ones in be quiet's silent wings fans.

The reason the noctua shown here seems to have more distinct behaviour as it comes to a stop is because it only just barely rotates over the magnetic pole at the last moment, whereas the other fans in the lineup came to a stop in between magnetic poles in the motor. Run the same test a bunch of times and you'd see the noctua's rotation look like the other fans the majority of the time.

The reason the noctua slowed faster is also obvious, and not at all related to the quality of the design or product - it simply has a great deal more mass at the tips of the blades due to the extreme sweep of them and the very shallow rake, whereas the noctua is an S12, which has almost no sweep and a very steep rake, thus most of it's mass is in the center and it also presents a flatter profile to the air which will also reduce it's ability to keep spinning. An A12, or F12, would have spun a great deal longer.

I'm fine with the colors; I don't ever use windowed cases or RGB bling with the only exception being my keyboard.