Tuesday, February 25th 2020

ZALMAN Rolls Out CNPS16X CPU Cooler and New Thermal Pastes

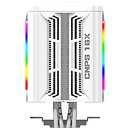

ZALMAN today announced market availability of its new CNPS16X tower-type CPU cooler and three new STC-series thermal compounds. The CNPS16X features an aluminium fin-stack tower-type heatsink that's ventilated by a pair of 120 mm fans in push-pull configuration, held together by an ABS shroud. The top-plate of this shroud features an addressable RGB embellishment with the ZALMAN logo at the center. Besides this, both fans feature ARGB diffusers along the bore of their frames. ZALMAN has two color variants of the CNPS16X depending on the color of the shroud - black and white. Splitter cables are included so the ARGB connections of both fans and the shroud are combined to a single 3-pin connection.

The design of the CNPS16X involves a direct-touch heatpipe base, from which four 6 mm-thick nickel-plated copper heat pipes pull heat, spreading it through the aluminium fin-stack. This stack features wave-shaped fins that make hexagonal patterns when viewed from the side. This design helps with increasing turbulence and heat-dissipation to the air-flow. Each of the two included 120 mm fans takes in 4-pin PWM, spins up to 1,500 RPM, together pushing around 75-90 m³h of air, with 25-29 dBA of noise output. ZALMAN rates the thermal capacity of this cooler at 150 W. Among the CPU socket types supported are AM4, LGA115x, and LGA2066. The CNPS16X is priced at 59.90€ (including taxes).In addition, ZALMAN introduced three new STC (super thermal compount) series TIMs, the STC-7, STC-8, and STC-9. The three are aluminium particle based pastes, composed of silicone oil base, aluminium particles, aluminium oxide, and zinc oxide. The STC-7 offers 7.2 W/mK thermal conductivity and is priced at 6.90€ for a 4 g syringe. The STC-8 only comes in 1.5 g syringes priced at 4.90€, and offers conductivity of 8.3 W/mK. The STC-9 leads the pack with 9.1 W/mK conductivity, and comes in 4 g syringes, priced at 9.90€ a pop.

The design of the CNPS16X involves a direct-touch heatpipe base, from which four 6 mm-thick nickel-plated copper heat pipes pull heat, spreading it through the aluminium fin-stack. This stack features wave-shaped fins that make hexagonal patterns when viewed from the side. This design helps with increasing turbulence and heat-dissipation to the air-flow. Each of the two included 120 mm fans takes in 4-pin PWM, spins up to 1,500 RPM, together pushing around 75-90 m³h of air, with 25-29 dBA of noise output. ZALMAN rates the thermal capacity of this cooler at 150 W. Among the CPU socket types supported are AM4, LGA115x, and LGA2066. The CNPS16X is priced at 59.90€ (including taxes).In addition, ZALMAN introduced three new STC (super thermal compount) series TIMs, the STC-7, STC-8, and STC-9. The three are aluminium particle based pastes, composed of silicone oil base, aluminium particles, aluminium oxide, and zinc oxide. The STC-7 offers 7.2 W/mK thermal conductivity and is priced at 6.90€ for a 4 g syringe. The STC-8 only comes in 1.5 g syringes priced at 4.90€, and offers conductivity of 8.3 W/mK. The STC-9 leads the pack with 9.1 W/mK conductivity, and comes in 4 g syringes, priced at 9.90€ a pop.

21 Comments on ZALMAN Rolls Out CNPS16X CPU Cooler and New Thermal Pastes

And those fins... what is that, nanowire?! This looks really poor

The shroud is a matter of personal taste but it's really not any more or less than any other cooler with a shroud.

Ergo, its shit. Repeating some marketing mantra about turbulence does not change a thing about that. De CNPS20X... hehe. Yeah. Let's see a proper review of that and not some random youtuber before we say its done well. I only saw one review of questionable quality. It could still be a good one, that. But this hunk of ABS? Definitely not.Precisely. All I see here is a Hyper 212 trying to look like more than it really is. 150W... haha good luck with that!

To be perfectly honest I don’t think this Zulman CNPS16X actually has a “Shroud”. You can see the fin stack from the side. This looks more like an overly elaborate fan mounting system (front and back fans in push / pull config),...along with an unnecessary plastic cap on the top. I don’t think it effects cooling much if at all though. The ARGB is unnecessary too but some people like that sort of thing.

Some server coolers have actual shrouds and these HSF solutions do indeed work just fine. So I don’t think it’s worth worrying about.

Having only 4 heat pipes seems like the real crime against humanity here,....IMO.

2 - Yeah, I agree I don't think it's going to affect much if anything to have that plastic there.

3 - Yep, server forced-air cooling setups are very, very efficient indeed and rely heavily on guided ariflow like this. They're not quiet, but they are incredibly space efficient for the heat loads they can handle - you could easily build silent systems with the same approach, it's just that server solutions never need to be quiet, they always need to be cool.

I suspect this is more of the same but I would be so happy to be proven wrong.

However, the fin density of this cooler looks depressing :(

Too be clear, this isn’t a HSF that I would suggest buying and I likely wouldn’t even try it if I had the opportunity.

However, as I suggested before, it’s not a shroud. This can be seen in the video quite clearly. It’s two nonstandard fans that clip on in an overly elaborate way yet still have side openings. There is also a separate top part. None of this should adversely effect performance although they could have just as easily went with the standard cheap wire clips and no ARGB.

The fin density actually doesn’t look all that bad in the video either but it’s hard to tell.

Again in some ways it reminds me of the Zulman FX70 which was also a little light on the fin density

The FX70 was sold as a passive cooler and thus came with no fans.

No plastic is a perfect insulator, it will transfer heat or cool just with a decent amount of resistance.

/Nerd moment over

Longer wire runs require greater Electromotive force/Potential Difference to move electrons in conductor itself but then you hit reactance/impedance (resistance) that it requires wire with larger cross section or short runs...

The angry electrons will plow through the lowest resistance path available. An insulator is just a poor conductor in reality.