Apr 13th, 2025 15:32 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- should global c-state be "enabled" instead of auto on am5 x3d processors? (25)

- What local LLM-s you use? (154)

- [electronics] - STREAM DECK during gaming? (2)

- Upgrade for a GTX-1060 video card to a X570 AM4 MB w/ a Ryzen 9 3900X (17)

- Dell Latitude 5420 - i7 1185G7 (3)

- Optical Disc Drive owners club (198)

- How to relubricate a fan and/or service a troublesome/noisy fan. (216)

- SK hynix A-Die (Overclocking thread) only for RYZEN AM5 users (30)

- Regarding fan noise (5)

- RX 9000 series GPU Owners Club (309)

Popular Reviews

- Thermaltake TR100 Review

- The Last Of Us Part 2 Performance Benchmark Review - 30 GPUs Compared

- TerraMaster F8 SSD Plus Review - Compact and quiet

- ASUS GeForce RTX 5080 TUF OC Review

- Zotac GeForce RTX 5070 Ti Amp Extreme Review

- ASRock Z890 Taichi OCF Review

- Sapphire Radeon RX 9070 XT Pulse Review

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- Upcoming Hardware Launches 2025 (Updated Apr 2025)

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

Controversial News Posts

- NVIDIA GeForce RTX 5060 Ti 16 GB SKU Likely Launching at $499, According to Supply Chain Leak (181)

- MSI Doesn't Plan Radeon RX 9000 Series GPUs, Skips AMD RDNA 4 Generation Entirely (146)

- Microsoft Introduces Copilot for Gaming (124)

- NVIDIA Sends MSRP Numbers to Partners: GeForce RTX 5060 Ti 8 GB at $379, RTX 5060 Ti 16 GB at $429 (123)

- Nintendo Confirms That Switch 2 Joy-Cons Will Not Utilize Hall Effect Stick Technology (105)

- Over 200,000 Sold Radeon RX 9070 and RX 9070 XT GPUs? AMD Says No Number was Given (100)

- Nintendo Switch 2 Launches June 5 at $449.99 with New Hardware and Games (99)

- NVIDIA PhysX and Flow Made Fully Open-Source (77)

News Posts matching #chip

Return to Keyword BrowsingTariffs Push US Wafer Fab Equipment Costs Up 15% for Domestic Fabs

As the US works to bring more semiconductor manufacturing back home, the machines needed to turn silicon into the world's most advanced processors are becoming pricier and harder to get, thanks to tariffs. Foundries building new fabs report that the specialized equipment they rely on, everything from extreme ultraviolet (EUV) lithography steppers to chemical vapor deposition chambers, carries a roughly 15% premium compared with similar gear sold overseas. Several forces are at play. The raw materials, high‑grade quartz for vacuum enclosures, and exotic metal alloys for precision optics have climbed in price. At the same time, key components like ultra‑accurate motion stages and alignment sensors are in short supply, sometimes stretching lead times for critical subsystems well beyond 18 months. For a fab racing to move from a 7 nm to a 5 nm process, those delays can mean missing tight ramp‑up targets and pushing out product launches.

Smaller chipmakers feel the squeeze the hardest. With fewer orders to negotiate volume discounts, second‑tier foundries may see their capital budgets balloon by 20 percent or more. In response, some are taking a mixed approach, sourcing commoditized tools such as oxidation furnaces and rapid thermal processors from multiple suppliers while reserving single‑vendor deals for high‑stakes systems like EUV scanners. Government support through the CHIPS Act offers a partial safety net, helping to subsidize capital expenditures. Yet even with grants and tax credits, the challenges will remain. Success will hinge on tight coordination between fabs, equipment makers, and policymakers to tame rising costs, shorten delivery schedules, and keep America's chip renaissance on track.

Smaller chipmakers feel the squeeze the hardest. With fewer orders to negotiate volume discounts, second‑tier foundries may see their capital budgets balloon by 20 percent or more. In response, some are taking a mixed approach, sourcing commoditized tools such as oxidation furnaces and rapid thermal processors from multiple suppliers while reserving single‑vendor deals for high‑stakes systems like EUV scanners. Government support through the CHIPS Act offers a partial safety net, helping to subsidize capital expenditures. Yet even with grants and tax credits, the challenges will remain. Success will hinge on tight coordination between fabs, equipment makers, and policymakers to tame rising costs, shorten delivery schedules, and keep America's chip renaissance on track.

Google Unveils Seventh-Generation AI Processor: Ironwood

Google has rolled out its seventh-generation AI chip, Ironwood, which aims to boost AI application performance. This processor focuses on "inference" computing—the quick calculations needed for chatbot answers and other AI outputs. Ironwood stands as one of the few real options to NVIDIA's leading AI processors coming from Google's ten-year multi-billion-dollar push to develop it. These tensor processing units (TPUs) are exclusively available through Google's cloud service or to its internal engineers.

According to Google Vice President Amin Vahdat, Ironwood combines functions from previously separate designs while increasing memory capacity. The chip can operate in groups of up to 9,216 processors and delivers twice the performance-per-energy ratio compared to last year's Trillium chip. When configured in pods of 9,216 chips, Ironwood delivers 42.5 Exaflops of computing power. This is more than 24 times the computational capacity of El Capitan, currently the world's largest supercomputer, which provides only 1.7 Exaflops per pod.

According to Google Vice President Amin Vahdat, Ironwood combines functions from previously separate designs while increasing memory capacity. The chip can operate in groups of up to 9,216 processors and delivers twice the performance-per-energy ratio compared to last year's Trillium chip. When configured in pods of 9,216 chips, Ironwood delivers 42.5 Exaflops of computing power. This is more than 24 times the computational capacity of El Capitan, currently the world's largest supercomputer, which provides only 1.7 Exaflops per pod.

Tenstorrent Launches Blackhole Developer Products at Tenstorrent Dev Day

Tenstorrent launched the next generation Blackhole chip family today at their DevDay event in San Francisco. Featuring all new RISC-V cores, Blackhole is built to handle massive AI workloads efficiently and offers an infinitely scalable solution.

Blackhole products are now available for order on tenstorrent.com:

Blackhole products are now available for order on tenstorrent.com:

- Blackhole p100, powered by one processor without Ethernet, active-cooled: available for $999

- Blackhole p150, powered by one processor with Ethernet, and available in passive-, active-, and liquid-cooled variants: available for $1,299

- TT-Quiet box, a liquid-cooled desktop workstation powered by 4 Blackhole processors: available for $11,999

GUC Announces Tape-Out of the World's First HBM4 IP on TSMC N3P

Global Unichip Corp. (GUC), the Advanced ASIC Leader, announced today that it has successfully taped-out the world's first HBM4 controller and PHY IP. This test chip was implemented using TSMC's cutting-edge N3P process technology and CoWoS -R advanced packaging technology.

The HBM4 IP supports data rates of up to 12 Gbps under all operating conditions. By leveraging a proprietary interposer layout, GUC has optimized signal integrity (SI) and power integrity (PI) to achieve these high speeds for all types of CoWoS technology. Comparing with HBM3, GUC's HBM4 PHY delivers 2.5x bandwidth while improving 1.5x power efficiency and 2x area efficiency. In line with previous GUC HBM, GLink, and UCIe IPs, this HBM4 IP integrates proteanTecs' interconnect monitoring solution to provide high visibility for testing and characterizing the PHY while improving in-field performance and reliability for end products.

The HBM4 IP supports data rates of up to 12 Gbps under all operating conditions. By leveraging a proprietary interposer layout, GUC has optimized signal integrity (SI) and power integrity (PI) to achieve these high speeds for all types of CoWoS technology. Comparing with HBM3, GUC's HBM4 PHY delivers 2.5x bandwidth while improving 1.5x power efficiency and 2x area efficiency. In line with previous GUC HBM, GLink, and UCIe IPs, this HBM4 IP integrates proteanTecs' interconnect monitoring solution to provide high visibility for testing and characterizing the PHY while improving in-field performance and reliability for end products.

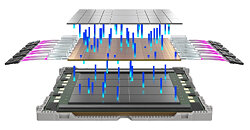

Lightmatter Unveils Passage M1000 Photonic Superchip

Lightmatter, the leader in photonic supercomputing, today announced Passage M1000, a groundbreaking 3D Photonic Superchip designed for next-generation XPUs and switches. The Passage M1000 enables a record-breaking 114 Tbps total optical bandwidth for the most demanding AI infrastructure applications. At more than 4,000 square millimeters, the M1000 reference platform is a multi-reticle active photonic interposer that enables the world's largest die complexes in a 3D package, providing connectivity to thousands of GPUs in a single domain.

In existing chip designs, interconnects for processors, memory, and I/O chiplets are bandwidth limited because electrical input/output (I/O) connections are restricted to the edges of these chips. The Passage M1000 overcomes this limitation by unleashing electro-optical I/O virtually anywhere on its surface for the die complex stacked on top. Pervasive interposer connectivity is enabled by an extensive and reconfigurable waveguide network that carries high-bandwidth WDM optical signals throughout the M1000. With fully integrated fiber attachment supporting an unprecedented 256 fibers, the M1000 delivers an order of magnitude higher bandwidth in a smaller package size compared to conventional Co-Packaged Optics (CPO) and similar offerings.

In existing chip designs, interconnects for processors, memory, and I/O chiplets are bandwidth limited because electrical input/output (I/O) connections are restricted to the edges of these chips. The Passage M1000 overcomes this limitation by unleashing electro-optical I/O virtually anywhere on its surface for the die complex stacked on top. Pervasive interposer connectivity is enabled by an extensive and reconfigurable waveguide network that carries high-bandwidth WDM optical signals throughout the M1000. With fully integrated fiber attachment supporting an unprecedented 256 fibers, the M1000 delivers an order of magnitude higher bandwidth in a smaller package size compared to conventional Co-Packaged Optics (CPO) and similar offerings.

xMEMS Introduces Lassen, Its First "Amplifier-Less" High-Performance MEMS Tweeter

xMEMS Labs, developers of the foremost platform for piezoMEMS innovation and creators of the world's leading all-silicon micro speakers, today announced xMEMS Lassen, the company's newest innovation for delivering micro fidelity (µFidelity) audio to mass-market consumer earbuds.

Responding to industrywide praise and enthusiastic reviews of xMEMS speaker technology for creating the highest quality sound, xMEMS has introduced Lassen, a lower cost all-silicon micro tweeter solution for TWS (True Wireless Stereo) earbuds.

Responding to industrywide praise and enthusiastic reviews of xMEMS speaker technology for creating the highest quality sound, xMEMS has introduced Lassen, a lower cost all-silicon micro tweeter solution for TWS (True Wireless Stereo) earbuds.

Rapidus Announces Strategic Partnership with Quest Global to Enable Advanced 2nm Solutions

Rapidus Corporation, a manufacturer of advanced logic semiconductors, today announced that it signed a Memorandum of Cooperation with Quest Global Services PTE. Ltd. As part of the agreement, Rapidus will become Quest Global's new semiconductor foundry partner, enabling it to provide a wide range of solutions to its customers. Quest Global customers will be able to leverage Rapidus' 2 nm gate-all-around (GAA) manufacturing process to develop engineering design and manufacturing solutions that will support growing industry demand for low-power artificial intelligence (AI) semiconductors. Together, the two companies will deliver transformational silicon solutions as a virtual integrated device manufacturer (IDM) model for fabless companies.

The AI semiconductor industry is in its early stages, with applications just beginning to emerge and new entrants quickly coming to market. Customers will shift from general-purpose AI semiconductors to dedicated designs that reduce power consumption and maximize performance. To support these industry requirements, customers will engage design firms focused on providing custom solutions, such as Quest Global, while also collaborating with semiconductor foundries, like Rapidus, that can manufacture dedicated semiconductors with a short turnaround time.

The AI semiconductor industry is in its early stages, with applications just beginning to emerge and new entrants quickly coming to market. Customers will shift from general-purpose AI semiconductors to dedicated designs that reduce power consumption and maximize performance. To support these industry requirements, customers will engage design firms focused on providing custom solutions, such as Quest Global, while also collaborating with semiconductor foundries, like Rapidus, that can manufacture dedicated semiconductors with a short turnaround time.

NVIDIA Plans US Supply Chain Investment Worth Hundreds of Billions, "Blackwell" Already Manufactured in Arizona

NVIDIA's CEO Jensen Huang made some interesting commentary for the Financial Times, stating that the company will procure over half a trillion US Dollars worth of electronics over the next four years, and it it plans to keep hundreds of billions from the supply chain procurement in the US. "Overall, we will procure, over the course of the next four years, probably half a trillion dollars worth of electronics in total. And I think we can easily see ourselves manufacturing several hundred billion of it here in the US," said Jensen for FT. NVIDIA currently manufactures its silicon at TSMC's facilities, as well as electronics like motherboards and servers at Foxconn. However, the geopolitical situation is making NVIDIA reconsider its supply chain dependencies, and the company is looking for more US-based manufacturing.

NVIDIA confirmed that its latest "Blackwell" series of GPUs, including the latest Blackwell Ultra, are being manufactured at TSMC's Arizona facilities. TSMC announced a $100 billion investment in its Arizona expansion, and NVIDIA is ready to take up more of TSMC's capacity to meet its ever-growing demand for GPUs. During the GTC 2025 event, Jensen noted that only four cloud service providers will use 3.6 million GPUs this year. That is without any AI labs and enterprises, which are massive consumers of GPUs (xAI only has 200,000 GPU clusters). To continue manufacturing excellence so customers won't suffer, NVIDIA is also looking at other options for supply chain manufacturing partners. Intel, the only US-based company capable of producing advanced silicon, is a potential target for NVIDIA. "We evaluate their foundry technology on a regular basis, and we are ongoing in doing that... We look for opportunities to be a customer of theirs... I have every confidence that Intel can do it," added Jensen, who also stated that NVIDIA is interested in silicon manufacturing and chip packaging services, as Intel's Foveros 3D packaging and other technologies are attractive for Team Green.

NVIDIA confirmed that its latest "Blackwell" series of GPUs, including the latest Blackwell Ultra, are being manufactured at TSMC's Arizona facilities. TSMC announced a $100 billion investment in its Arizona expansion, and NVIDIA is ready to take up more of TSMC's capacity to meet its ever-growing demand for GPUs. During the GTC 2025 event, Jensen noted that only four cloud service providers will use 3.6 million GPUs this year. That is without any AI labs and enterprises, which are massive consumers of GPUs (xAI only has 200,000 GPU clusters). To continue manufacturing excellence so customers won't suffer, NVIDIA is also looking at other options for supply chain manufacturing partners. Intel, the only US-based company capable of producing advanced silicon, is a potential target for NVIDIA. "We evaluate their foundry technology on a regular basis, and we are ongoing in doing that... We look for opportunities to be a customer of theirs... I have every confidence that Intel can do it," added Jensen, who also stated that NVIDIA is interested in silicon manufacturing and chip packaging services, as Intel's Foveros 3D packaging and other technologies are attractive for Team Green.

Vietnam to Begin First Wafer Fab Construction, Eyes Semiconductor Leadership in the Coming Decade

Vietnam's government has approved its first wafer fab facility, with an investment of 12.8 trillion VND (approximately $500 million). The first phase of the facility, scheduled for completion by 2030, is designed to manufacture specialized chips for defense, AI, and other high-tech applications. The project will receive government backing through direct funding—covering up to 30% of the total investment, capped at 10 trillion VND—and tax incentives. A special steering committee headed by the Prime Minister has been tasked with overseeing the project's execution and resource allocation. The new fab is a critical component of Vietnam's long-term semiconductor strategy, a phased approach toward building a domestic ecosystem for chip design, manufacturing, and testing. The current investment is modest compared to the typical costs of advanced wafer fabs, which can reach up to $50 billion.

Nonetheless, the project is a foundational, one-step-at-the-time move intended to spur further investments and technology transfer. Vietnamese officials have reportedly engaged in discussions with major international chip manufacturers—including US, South Korea, and Taiwan entities, such as GlobalFoundries and Powerchip Semiconductor Manufacturing Corp—to explore potential collaborative opportunities. Vietnam already hosts 174 semiconductor-related projects, predominantly focused on chip packaging and testing, in which global companies like Intel and Amkor have established significant operations. The second phase, from 2030-2040, envisions Vietnam emerging as a worldwide center for electronics and semiconductors. By expanding to at least 200 design companies, establishing two semiconductor chip manufacturing plants, and creating 15 packaging and testing facilities, the country intends to gradually develop independent semiconductor product design and production capabilities.

Nonetheless, the project is a foundational, one-step-at-the-time move intended to spur further investments and technology transfer. Vietnamese officials have reportedly engaged in discussions with major international chip manufacturers—including US, South Korea, and Taiwan entities, such as GlobalFoundries and Powerchip Semiconductor Manufacturing Corp—to explore potential collaborative opportunities. Vietnam already hosts 174 semiconductor-related projects, predominantly focused on chip packaging and testing, in which global companies like Intel and Amkor have established significant operations. The second phase, from 2030-2040, envisions Vietnam emerging as a worldwide center for electronics and semiconductors. By expanding to at least 200 design companies, establishing two semiconductor chip manufacturing plants, and creating 15 packaging and testing facilities, the country intends to gradually develop independent semiconductor product design and production capabilities.

US Self-Sufficiency of Semiconductors Unlikely According to Japanese Expert

According to Akira Amari, a Japanese politician and semiconductor industry expert, it's unlikely that the US will ever reach self-sufficiency when it comes to semiconductor production. This has nothing to do with foundries, as the US might manage to be self-sufficient in terms or raw chip production needs, but the country is said to be unlikely to be able to reach a complete supply chain of everything else needed to produce the chips. Countries like Japan, Taiwan, the Netherlands, Belgium, South Korea and more are heavily invested in supplying not only components needed to produce semiconductors, but also machinery and chemicals.

Amari is suggesting that these countries should form a co-operative alliance to help strengthen their supply chains at home, rather than putting all eggs in one basket to try and appease the US. This statement comes after TSMC promised to invest an additional US$100 billion over an unspecified time frame in the US. Time will tell if he's right or not, but it's unlikely that any country will ever be self-sufficient when it comes to making semiconductors, regardless of how big they are or what natural resources they have access to locally.

Amari is suggesting that these countries should form a co-operative alliance to help strengthen their supply chains at home, rather than putting all eggs in one basket to try and appease the US. This statement comes after TSMC promised to invest an additional US$100 billion over an unspecified time frame in the US. Time will tell if he's right or not, but it's unlikely that any country will ever be self-sufficient when it comes to making semiconductors, regardless of how big they are or what natural resources they have access to locally.

Global Top 10 IC Design Houses See 49% YoY Growth in 2024, NVIDIA Commands Half the Market

TrendForce reveals that the combined revenue of the world's top 10 IC design houses reached approximately US$249.8 billion in 2024, marking a 49% YoY increase. The booming AI industry has fueled growth across the semiconductor sector, with NVIDIA leading the charge, posting an astonishing 125% revenue growth, widening its lead over competitors, and solidifying its dominance in the IC industry.

Looking ahead to 2025, advancements in semiconductor manufacturing will further enhance AI computing power, with LLMs continuing to emerge. Open-source models like DeepSeek could lower AI adoption costs, accelerating AI penetration from servers to personal devices. This shift positions edge AI devices as the next major growth driver for the semiconductor industry.

Looking ahead to 2025, advancements in semiconductor manufacturing will further enhance AI computing power, with LLMs continuing to emerge. Open-source models like DeepSeek could lower AI adoption costs, accelerating AI penetration from servers to personal devices. This shift positions edge AI devices as the next major growth driver for the semiconductor industry.

4Q24 Global Top 10 Foundries Set New Revenue Record, TSMC Leads in Advanced Process Nodes

TrendForce's latest research reveals that the global foundry industry exhibited a polarized trend in 4Q24. Advanced process nodes benefited from strong demand in AI servers, flagship smartphone application processors (APs), and new PC platforms, driving high-value wafer shipments. This growth helped offset the slowdown in mature process demand, allowing the top 10 foundries to achieve nearly 10% QoQ revenue growth, reaching US$38.48 billion, and marking another industry record.

TrendForce notes that new U.S. trade tariffs under the Trump administration have started affecting the foundry industry. A surge in recent orders for TVs, PCs, and notebooks bound for the U.S. in 4Q24 is expected to extend into 1Q25. Additionally, China's consumer subsidy program—introduced in late 2024—has spurred early inventory restocking among upstream customers. Combined with persistent demand for TSMC's AI-related chips and advanced packaging, these factors suggest that despite Q1 being a seasonally weak quarter, foundry revenue will only decline slightly.

TrendForce notes that new U.S. trade tariffs under the Trump administration have started affecting the foundry industry. A surge in recent orders for TVs, PCs, and notebooks bound for the U.S. in 4Q24 is expected to extend into 1Q25. Additionally, China's consumer subsidy program—introduced in late 2024—has spurred early inventory restocking among upstream customers. Combined with persistent demand for TSMC's AI-related chips and advanced packaging, these factors suggest that despite Q1 being a seasonally weak quarter, foundry revenue will only decline slightly.

Codasip Selected to Design a High-End RISC-V Processor for the EU-Funded DARE Project

Codasip, the European RISC-V leader, announced that it has been selected to provide a general purpose, high-end processor as part of the large-scale European supercomputing project Digital Autonomy with RISC-V in Europe (DARE).

DARE is set to build a supercomputing compute stack, featuring high-performance and energy-efficient RISC-V-based processors and accelerators designed and developed in Europe. The European Union has committed 240 million Euros in funding for the first 3-year program phase. The selected partners will leverage hardware/software co-design to achieve competitive performance and efficiency.

DARE is set to build a supercomputing compute stack, featuring high-performance and energy-efficient RISC-V-based processors and accelerators designed and developed in Europe. The European Union has committed 240 million Euros in funding for the first 3-year program phase. The selected partners will leverage hardware/software co-design to achieve competitive performance and efficiency.

SK keyfoundry Launches 3D Hall-effect Sensor Technology Capable of Measuring Speed and Direction

SK keyfoundry, an 8-inch pure-play foundry in Korea, announced today that it offers a new 3D Hall-effect sensor technology that can measure speed and direction through three-dimensional magnetic field detection for its foundry customers.

The Hall-effect sensor is a device that measures the strength of a magnetic field using the Hall-effect, which detects the voltage difference generated when a conductor or semiconductor passes through a magnetic field. The measured magnetic field is utilized in applications that leverage the position, speed, rotation, direction, and current of devices.

The Hall-effect sensor is a device that measures the strength of a magnetic field using the Hall-effect, which detects the voltage difference generated when a conductor or semiconductor passes through a magnetic field. The measured magnetic field is utilized in applications that leverage the position, speed, rotation, direction, and current of devices.

Microchip Technology Releases MPLAB PICkit Basic Debugger

To make its robust programming and debugging capabilities accessible to a wider range of engineers, Microchip Technology has launched the MPLAB PICkit Basic in-circuit debugger as a cost-effective, powerful solution for engineers at various levels. Unlike other complex and expensive debuggers, this budget-friendly device offers high-speed USB 2.0 connectivity, CMSIS-DAP support, compatibility with various Integrated Development Environments (IDEs) and compatibility with a broad range of microcontrollers. The tool's versatility allows developers to use the debugger across various projects and platforms—including VS Code ecosystems—to simplify the workflow and reduce the need for multiple tools.

Key features:

Key features:

- USB Type-C Cable: The MPLAB PICkit Basic programmer debugger uses a USB Type-C cable, which is modern, widely adopted and easy to use. The USB-C connection helps promote better connectivity, faster data transfer and a more reliable connection, reducing the hassle of dealing with outdated or incompatible cables.

Marvell Demonstrates Industry's Leading 2nm Silicon for Accelerated Infrastructure

Marvell Technology, Inc., a leader in data infrastructure semiconductor solutions, has demonstrated its first 2 nm silicon IP for next-generation AI and cloud infrastructure. Produced on TSMC's 2 nm process, the working silicon is part of the Marvell platform for developing custom XPUs, switches and other technology to help cloud service providers elevate the performance, efficiency, and economic potential of their worldwide operations.

Given a projected 45% TAM growth annually, custom silicon is expected to account for approximately 25% of the market for accelerated compute by 20281.

Given a projected 45% TAM growth annually, custom silicon is expected to account for approximately 25% of the market for accelerated compute by 20281.

SOPHGO Unveils New Products at the 2025 China RISC-V Ecosystem Conference

On February 27-28, the 2025 China RISC-V Ecosystem Conference was grandly held at the Zhongguancun International Innovation Center in Beijing. As a core promoter in the RISC-V field, SOPHGO was invited to deliver a speech and prominently launch a series of new products based on the SG2044 chip, sharing the company's cutting-edge practices in the heterogeneous fusion of AI and RISC-V, and contributing to the vigorous development of the global open-source instruction set ecosystem. During the conference, SOPHGO set up a distinctive exhibition area that attracted many attendees from the industry to stop and watch.

Focusing on AI Integration, Leading Breakthroughs in RISC-V Technology

At the main forum of the conference, the Vice President of SOPHGO RISC-V delivered a speech titled "RISC-V Breakthroughs Driven by AI: Integration + Heterogeneous Innovation," where he elaborated on SOPHGO's innovative achievements in the deep integration of RISC-V architecture and artificial intelligence technology. He pointed out that current AI technological innovations are driving market changes, and the emergence of DeepSeek has ignited a trillion-level computing power market. The innovation of technical paradigms and the penetration of large models into various sectors will lead to an explosive growth in inference demand, resulting in changes in the structure of computing power demand. This will also reshape the landscape of the computing power market, bringing significant business opportunities to domestic computing power enterprises, while RISC-V high-performance computing is entering a fast track of development driven by AI.

Focusing on AI Integration, Leading Breakthroughs in RISC-V Technology

At the main forum of the conference, the Vice President of SOPHGO RISC-V delivered a speech titled "RISC-V Breakthroughs Driven by AI: Integration + Heterogeneous Innovation," where he elaborated on SOPHGO's innovative achievements in the deep integration of RISC-V architecture and artificial intelligence technology. He pointed out that current AI technological innovations are driving market changes, and the emergence of DeepSeek has ignited a trillion-level computing power market. The innovation of technical paradigms and the penetration of large models into various sectors will lead to an explosive growth in inference demand, resulting in changes in the structure of computing power demand. This will also reshape the landscape of the computing power market, bringing significant business opportunities to domestic computing power enterprises, while RISC-V high-performance computing is entering a fast track of development driven by AI.

GlobalFoundries and MIT Collaborate on Photonic AI Chips

GlobalFoundries (GF) and the Massachusetts Institute of Technology (MIT) today announced a new master research agreement to jointly pursue advancements and innovations for enhancing the performance and efficiency of critical semiconductor technologies. The collaboration will be led by MIT's Microsystems Technology Laboratories (MTL) and GF's research and development team, GF Labs.

With an initial research focus on AI and other applications, the first projects are expected to leverage GF's differentiated silicon photonics technology, which monolithically integrates RF SOI, CMOS and optical features on a single chip to realize power efficiencies for datacenters, and GF's 22FDX platform, which delivers ultra-low power consumption for intelligent devices at the edge.

With an initial research focus on AI and other applications, the first projects are expected to leverage GF's differentiated silicon photonics technology, which monolithically integrates RF SOI, CMOS and optical features on a single chip to realize power efficiencies for datacenters, and GF's 22FDX platform, which delivers ultra-low power consumption for intelligent devices at the edge.

Amazon Web Services Announces New Quantum Computing Chip

Today, Amazon Web Services (AWS) announced Ocelot, a new quantum computing chip that can reduce the costs of implementing quantum error correction by up to 90%, compared to current approaches. Developed by the team at the AWS Center for Quantum Computing at the California Institute of Technology, Ocelot represents a breakthrough in the pursuit to build fault-tolerant quantum computers capable of solving problems of commercial and scientific importance that are beyond the reach of today's conventional computers.

AWS used a novel design for Ocelot's architecture, building error correction in from the ground up and using the 'cat qubit'. Cat qubits-named after the famous Schrödinger's cat thought experiment-intrinsically suppress certain forms of errors, reducing the resources required for quantum error correction. Through this new approach with Ocelot, AWS researchers have, for the first time, combined cat qubit technology and additional quantum error correction components onto a microchip that can be manufactured in a scalable fashion using processes borrowed from the microelectronics industry.

AWS used a novel design for Ocelot's architecture, building error correction in from the ground up and using the 'cat qubit'. Cat qubits-named after the famous Schrödinger's cat thought experiment-intrinsically suppress certain forms of errors, reducing the resources required for quantum error correction. Through this new approach with Ocelot, AWS researchers have, for the first time, combined cat qubit technology and additional quantum error correction components onto a microchip that can be manufactured in a scalable fashion using processes borrowed from the microelectronics industry.

Open Compute Project Foundation and JEDEC Announce New Chiplet Design Kits

Today, the Open Compute Project Foundation (OCP), the nonprofit organization bringing hyperscale innovations to all, and JEDEC Solid State Technology Association, the global leader in the development of standards for the microelectronics industry, announce the availability of new Chiplet Design Kits for use with today's EDA tools covering Assembly, Substrate, Material and Test developed in collaboration within the OCP Open Chiplet Economy Project. Leveraging the alliance between OCP and JEDEC, these design kits are now part of the Global Worldwide Standard JEDEC JEP30: Part Model Guidelines.

The release of the Assembly, Substrate, Material, and Test Design Kits build on earlier joint efforts between the OCP and JEDEC integrating OCP Chiplet Data Extensible Markup Language (CDXML) specification into JEDEC JEP30: Part Model Guidelines, enabling Chiplet builders to provide electronically a standardized Chiplet part description to their customers, paving the way for automating System-in-Package (SiP) design and build using Chiplets.

The release of the Assembly, Substrate, Material, and Test Design Kits build on earlier joint efforts between the OCP and JEDEC integrating OCP Chiplet Data Extensible Markup Language (CDXML) specification into JEDEC JEP30: Part Model Guidelines, enabling Chiplet builders to provide electronically a standardized Chiplet part description to their customers, paving the way for automating System-in-Package (SiP) design and build using Chiplets.

Baya Systems and Semidynamics Collaborate to Accelerate RISC-V System-on-Chip Development

Baya Systems, a leader in system IP technology that empowers the acceleration of intelligent compute, and Semidynamics, a provider of fully customizable high-bandwidth and high-performance RISC-V processor IP, today announced a collaboration to boost innovation in development of hyper-efficient, next-generation platforms for artificial intelligence (AI), machine learning (ML) and high-performance computing (HPC) applications.

The collaboration integrates Semidynamics' family of 64-bit RISC-V processor IP cores, known for their exceptional memory bandwidth and configurability, with Baya Systems' innovative WeaveIP Network on Chip (NoC) system IP. WeaveIP is engineered for ultra-efficient, high-bandwidth, and low-latency data transport, crucial for the demands of modern workloads. Complementing this is Baya Systems' software-driven WeaverPro platform, which enables rapid system-level optimization, ensuring that key performance indicators (KPIs) are met based on real-world workloads while providing unparalleled design flexibility for future advancements.

The collaboration integrates Semidynamics' family of 64-bit RISC-V processor IP cores, known for their exceptional memory bandwidth and configurability, with Baya Systems' innovative WeaveIP Network on Chip (NoC) system IP. WeaveIP is engineered for ultra-efficient, high-bandwidth, and low-latency data transport, crucial for the demands of modern workloads. Complementing this is Baya Systems' software-driven WeaverPro platform, which enables rapid system-level optimization, ensuring that key performance indicators (KPIs) are met based on real-world workloads while providing unparalleled design flexibility for future advancements.

Apple to Spend More Than $500 Billion in the U.S. Over the Next Four Years

Apple today announced its largest-ever spend commitment, with plans to spend and invest more than $500 billion in the U.S. over the next four years. This new pledge builds on Apple's long history of investing in American innovation and advanced high-skilled manufacturing, and will support a wide range of initiatives that focus on artificial intelligence, silicon engineering, and skills development for students and workers across the country.

"We are bullish on the future of American innovation, and we're proud to build on our long-standing U.S. investments with this $500 billion commitment to our country's future," said Tim Cook, Apple's CEO. "From doubling our Advanced Manufacturing Fund, to building advanced technology in Texas, we're thrilled to expand our support for American manufacturing. And we'll keep working with people and companies across this country to help write an extraordinary new chapter in the history of American innovation."

"We are bullish on the future of American innovation, and we're proud to build on our long-standing U.S. investments with this $500 billion commitment to our country's future," said Tim Cook, Apple's CEO. "From doubling our Advanced Manufacturing Fund, to building advanced technology in Texas, we're thrilled to expand our support for American manufacturing. And we'll keep working with people and companies across this country to help write an extraordinary new chapter in the history of American innovation."

Global Semiconductor Manufacturing Industry Reports Solid Q4 2024 Results

The global semiconductor manufacturing industry closed 2024 with strong fourth quarter results and solid year-on-year (YoY) growth across most of the key industry segments, SEMI announced today in its Q4 2024 publication of the Semiconductor Manufacturing Monitor (SMM) Report, prepared in partnership with TechInsights. The industry outlook is cautiously optimistic at the start of 2025 as seasonality and macroeconomic uncertainty may impede near-term growth despite momentum from strong investments related to AI applications.

After declining in the first half of 2024, electronics sales bounced back later in the year resulting in a 2% annual increase. Electronics sales grew 4% YoY in Q4 2024 and are expected to see a 1% YoY increase in Q1 2025 impacted by seasonality. Integrated circuit (IC) sales rose by 29% YoY in Q4 2024 and continued growth is expected in Q1 2025 with a 23% increase YoY as AI-fueled demand continues boosting shipments of high-performance computing (HPC) and datacenter memory chips.

After declining in the first half of 2024, electronics sales bounced back later in the year resulting in a 2% annual increase. Electronics sales grew 4% YoY in Q4 2024 and are expected to see a 1% YoY increase in Q1 2025 impacted by seasonality. Integrated circuit (IC) sales rose by 29% YoY in Q4 2024 and continued growth is expected in Q1 2025 with a 23% increase YoY as AI-fueled demand continues boosting shipments of high-performance computing (HPC) and datacenter memory chips.

Arm to Develop In-House Server CPUs, Signs Meta as First Customer

Reports from Financial Times suggest Arm has plans to create its own CPU, set to hit the market in 2025 with Meta Platforms said to be one of the first customers. The chip is said to be a CPU for data center servers, with TSMC handling the manufacturing. However, when the Financial Times asked about this, SoftBank (the majority owner of Arm) and Meta stayed quiet, while Arm didn't give a statement. A Nikkei report from May 2024 suggested that a prototype AI processor chip would be completed by spring 2025 and available for sale by fall 2025, so the latest information from the Financial Times report feels like a confirmation of previous rumors.

Right now, Arm makes money by letting others use its instruction set and core designs to make their own chips. This new move could mean Arm will compete with its current customers. Sources in the industry say Arm is trying to win business from Qualcomm, with rumors that Arm has been bringing in executives from companies it works with to help develop this chip. While Qualcomm had talked in the past about giving Meta a data center CPU using Arm's design, it looks like Arm has won at least some of that deal. However, no technical or specification details are available currently for Arm's 1st in-house server CPU.

Right now, Arm makes money by letting others use its instruction set and core designs to make their own chips. This new move could mean Arm will compete with its current customers. Sources in the industry say Arm is trying to win business from Qualcomm, with rumors that Arm has been bringing in executives from companies it works with to help develop this chip. While Qualcomm had talked in the past about giving Meta a data center CPU using Arm's design, it looks like Arm has won at least some of that deal. However, no technical or specification details are available currently for Arm's 1st in-house server CPU.

China's Semiconductor Equipment Spending to Decline in 2025, First Decline in Recent Years

China's dominance in semiconductor equipment procurement is expected to face its first setback since 2021, with spending projected to decrease from $41 billion to $38 billion in 2025, according to semiconductor research firm TechInsights. This 6% decline marks a significant shift for the world's largest buyer of wafer fabrication equipment, whose purchases represented 40% of global sales in 2024. The downturn reflects mounting pressures from both market dynamics and geopolitical constraints. US export controls targeting advanced semiconductor capabilities have intensified while domestic chipmakers grapple with overcapacity in mature node segments. SMIC, China's leading foundry, has already signaled concerns about oversupply risks in this sector, where Chinese manufacturers have rapidly expanded their market share against Taiwanese competitors.

Despite these headwinds, Chinese equipment manufacturers have notably advanced domestic capability development. Naura Technology Group has emerged as the seventh-largest global equipment manufacturer, while AMEC continues to expand its international presence. However, critical gaps persist in China's semiconductor equipment ecosystem, particularly in lithography systems, where dependence on foreign suppliers like ASML remains high. TechInsights data reveals that Chinese companies supplied only 17% of testing tools and 10% of domestic assembly equipment in 2023. The spending reduction comes after a period of aggressive stockpiling prompted by US sanctions to limit Beijing's access to advanced chipmaking capabilities, especially those applicable to artificial intelligence and military applications. However, Chinese manufacturers have demonstrated resilience, with SMIC and Huawei successfully producing advanced chips through alternative, albeit more costly, manufacturing methods.

Despite these headwinds, Chinese equipment manufacturers have notably advanced domestic capability development. Naura Technology Group has emerged as the seventh-largest global equipment manufacturer, while AMEC continues to expand its international presence. However, critical gaps persist in China's semiconductor equipment ecosystem, particularly in lithography systems, where dependence on foreign suppliers like ASML remains high. TechInsights data reveals that Chinese companies supplied only 17% of testing tools and 10% of domestic assembly equipment in 2023. The spending reduction comes after a period of aggressive stockpiling prompted by US sanctions to limit Beijing's access to advanced chipmaking capabilities, especially those applicable to artificial intelligence and military applications. However, Chinese manufacturers have demonstrated resilience, with SMIC and Huawei successfully producing advanced chips through alternative, albeit more costly, manufacturing methods.

Apr 13th, 2025 15:32 EDT

change timezone

Latest GPU Drivers

New Forum Posts

- should global c-state be "enabled" instead of auto on am5 x3d processors? (25)

- What local LLM-s you use? (154)

- [electronics] - STREAM DECK during gaming? (2)

- Upgrade for a GTX-1060 video card to a X570 AM4 MB w/ a Ryzen 9 3900X (17)

- Dell Latitude 5420 - i7 1185G7 (3)

- Optical Disc Drive owners club (198)

- How to relubricate a fan and/or service a troublesome/noisy fan. (216)

- SK hynix A-Die (Overclocking thread) only for RYZEN AM5 users (30)

- Regarding fan noise (5)

- RX 9000 series GPU Owners Club (309)

Popular Reviews

- Thermaltake TR100 Review

- The Last Of Us Part 2 Performance Benchmark Review - 30 GPUs Compared

- TerraMaster F8 SSD Plus Review - Compact and quiet

- ASUS GeForce RTX 5080 TUF OC Review

- Zotac GeForce RTX 5070 Ti Amp Extreme Review

- ASRock Z890 Taichi OCF Review

- Sapphire Radeon RX 9070 XT Pulse Review

- Sapphire Radeon RX 9070 XT Nitro+ Review - Beating NVIDIA

- Upcoming Hardware Launches 2025 (Updated Apr 2025)

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

Controversial News Posts

- NVIDIA GeForce RTX 5060 Ti 16 GB SKU Likely Launching at $499, According to Supply Chain Leak (181)

- MSI Doesn't Plan Radeon RX 9000 Series GPUs, Skips AMD RDNA 4 Generation Entirely (146)

- Microsoft Introduces Copilot for Gaming (124)

- NVIDIA Sends MSRP Numbers to Partners: GeForce RTX 5060 Ti 8 GB at $379, RTX 5060 Ti 16 GB at $429 (123)

- Nintendo Confirms That Switch 2 Joy-Cons Will Not Utilize Hall Effect Stick Technology (105)

- Over 200,000 Sold Radeon RX 9070 and RX 9070 XT GPUs? AMD Says No Number was Given (100)

- Nintendo Switch 2 Launches June 5 at $449.99 with New Hardware and Games (99)

- NVIDIA PhysX and Flow Made Fully Open-Source (77)