US Targets ASML With $1B Lithography Center in Albany, New York

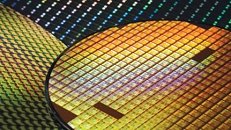

Today, the Department of Commerce and Natcast, the operator of the National Semiconductor Technology Center (NSTC), announced the expected location for the first CHIPS for America research and development (R&D) flagship facility. The CHIPS for America Extreme Ultraviolet (EUV) Accelerator, an NSTC facility (EUV Accelerator), is expected to operate within NY CREATES' Albany NanoTech Complex in Albany, New York, supported by a proposed federal investment of an estimated $825 million. The EUV Accelerator will focus on advancing state of the art EUV technology and the R&D that relies on it.

As a key part of President Biden's Investing in America agenda, CHIPS for America is driven by the growing need to bolster the U.S. semiconductor supply chain, accelerate U.S. leading-edge R&D, and create good quality jobs around the country. This proposed facility will bring together NSTC members from across the ecosystem to accelerate semiconductor R&D and innovation by providing NSTC members access to technologies, capabilities, and critical resources.

As a key part of President Biden's Investing in America agenda, CHIPS for America is driven by the growing need to bolster the U.S. semiconductor supply chain, accelerate U.S. leading-edge R&D, and create good quality jobs around the country. This proposed facility will bring together NSTC members from across the ecosystem to accelerate semiconductor R&D and innovation by providing NSTC members access to technologies, capabilities, and critical resources.