3

3

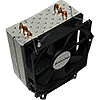

Zaward Vapor 120 Review

Installation »A closer look

Zaward Vapor 120 sports a unique design methodology. Its designs sought to minimize the metal content in the heatsink by simply optimizing the way each aluminum fin is designed. The aluminum fins have numerous tiny dimples which are punched. This increases surface area and turbulence, while keeping the heatsink compact. Width and height-wise, Vapor 120 is a typical-looking tower-type heatsink. It's only with a depth of just 50 mm, the Vapor 120 is a slim heatsink. The fin array is symmetrical, with provision to attach fans on either sides.

The 120 mm fan packed with the Vapor 120 is a medium~high speed blue-illuminated fan, rated to move up to 93.96 CFM of air. Despite spinning at speeds of up to 2000 RPM (±10%), which should have a ballpark rated air-flow in the 80's CFM the fan is able to push that much of air, because it is said to have adopted a more efficient impeller blade design. The golf-ball dimples on the surface of the blades increase turbulence, in turn stepping up air-flow per RPM.

The frame and impeller are made of tough ABS plastic. The cable is sleeved, a very nice touch. The fan uses a standard 4-pin connector, which can connect to almost all current motherboards' CPU fan headers. It supports pulse-width modulation (PWM) method of fan-speed control, voltage-based method is naturally supported, in case you decide to plug the fan into a standard 3-pin fan header on the motherboard, instead. An increasing number of motherboards these days are letting you select between the two kinds of speed control in the BIOS setup, with the fan plugged in to the CPU fan header.

Despite having an opaque frame and impeller, the fan features a mild illumination. On each of the four corners of the frame, a blue LED is fixed with a small hole to project light on to the impeller. This gives the fan a milder illumination than in fans that use transparent or translucent parts.

The Vapor 120 uses three 8 mm thick copper heat pipes that are bent in a U-shape, passing through the CPU base. The pipes pass through the aluminum fins in a uniform file and not scattered. While this might help aesthetics, it isn't a great boost for heat-dissipation. Perhaps the central pipe could have been made to pass through the central portion of the aluminum fins, allowing a more uniform dissipation, and also stepping up air-turbulence.

There's also a close-up of the fin surface showing the punched dimples. Besides stepping up surface area of the fins and adding to the turbulence, the punched holes, according to Zaward, also produces what it calls the "heatsink breathing effect". Simply put, the holes allow for some transfer of air between the fin planes, some of which could be convectional. Since fins towards the top are slightly cooler than fins closer to the base, I would imagine some sort of a convectional current to move towards lower parts of the fin array.

The Vapor 120 uses a heat pipe direct-touch CPU base, a design in which the heat pipes that transport heat to the aluminum fin array, make direct contact with the CPU IHS, eliminating the need for a base-plate that could add some thermal-resistance. The flip-side of this approach is that the gaps between the pipes and the base serve as crevices, where thermal-compound can seep in. Thicker portions of thermal compound can then actually increase thermal resistance. Zaward milled the Vapor 120's base very well, the smaller the number of heatpipes, the lesser are the crevices.

Jul 12th, 2025 01:19 CDT

change timezone

Latest GPU Drivers

New Forum Posts

- Will you buy a RTX 5090? (642)

- 'NVIDIA App' not usable offline? (8)

- Can you guess Which game it is? (222)

- What are you playing? (23920)

- RX 9070 XT freezing/locking up only on desktop, anyone else? (43)

- NVIDIA RTX PRO 6000 Workstation Runs Much Hotter Than 5090 FE (22)

- Quick charging your USB devicesUSB 3.2 Gen 2x2 Type-C® front-panel. (1)

- GTX 1050 GPU Owners Club (12)

- ASUS ProArt GeForce RTX 4060 Ti OC Edition 16GB GDDR6 Gaming - nvflash64 VBIOS mismatch (2)

- No offense, here are some things that bother me about your understanding of fans. (33)

Popular Reviews

- Fractal Design Epoch RGB TG Review

- Corsair FRAME 5000D RS Review

- Lexar NM1090 Pro 4 TB Review

- NVIDIA GeForce RTX 5050 8 GB Review

- NZXT N9 X870E Review

- Sapphire Radeon RX 9060 XT Pulse OC 16 GB Review - An Excellent Choice

- AMD Ryzen 7 9800X3D Review - The Best Gaming Processor

- Upcoming Hardware Launches 2025 (Updated May 2025)

- Our Visit to the Hunter Super Computer

- Chieftec Iceberg 360 Review

TPU on YouTube

Controversial News Posts

- Intel's Core Ultra 7 265K and 265KF CPUs Dip Below $250 (288)

- Some Intel Nova Lake CPUs Rumored to Challenge AMD's 3D V-Cache in Desktop Gaming (140)

- AMD Radeon RX 9070 XT Gains 9% Performance at 1440p with Latest Driver, Beats RTX 5070 Ti (131)

- NVIDIA Launches GeForce RTX 5050 for Desktops and Laptops, Starts at $249 (119)

- NVIDIA GeForce RTX 5080 SUPER Could Feature 24 GB Memory, Increased Power Limits (115)

- Microsoft Partners with AMD for Next-gen Xbox Hardware (105)

- Intel "Nova Lake‑S" Series: Seven SKUs, Up to 52 Cores and 150 W TDP (100)

- NVIDIA DLSS Transformer Cuts VRAM Usage by 20% (97)