Friday, June 26th 2009

Hard Rectangular Drive Could be the Hard Disk Answer to SSDs

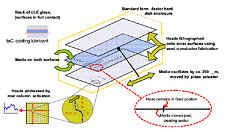

A company called DataSlide has decided its not time for mechanical disk drives also known as hard disk drives (HDD) to roll over and die with SSDs beating them in just about every aspect other than price. The key aspect of the new technology is that it does not require the data platter to be spun like conventional hard disk drives do. For a start this provides savings in power consumption and due to the use of magnetic recording media as found in hard disk drives should allow the hard rectanguar drive (HRD) to be cheaper than an SSD or at least provide significantly more usable space for your money. A diagram explaining the technology and the manufacturers details and specifications follow.DataSlide's Hard Rectangular Drive (HRD) capitalizes on standard base process technologies to create a dramatically new way to store and retrieve data with magnetic media:

1. Leverage LCD process

2. Use standard HDD sputtering/plating MEMS process

3. Use HDD perpendicular media DSSC/Oerlikon-Balzers coatings

DataSlide applies technology in new, patented ways to achieve unprecedented high performance

160,000 IOPS & 500MB/sec and low power <4 Watts for a magnetic storage device:

1. A piezoelectric actuator keeps the rectangular media in precise motion

2. A diamond solid lubricant coating protects the surfaces for years of worry free service

3. A massively parallel 2D array of magnetic heads reads from or writes to up to 64 embedded heads at a time

Source:

DataSlide

1. Leverage LCD process

2. Use standard HDD sputtering/plating MEMS process

3. Use HDD perpendicular media DSSC/Oerlikon-Balzers coatings

DataSlide applies technology in new, patented ways to achieve unprecedented high performance

160,000 IOPS & 500MB/sec and low power <4 Watts for a magnetic storage device:

1. A piezoelectric actuator keeps the rectangular media in precise motion

2. A diamond solid lubricant coating protects the surfaces for years of worry free service

3. A massively parallel 2D array of magnetic heads reads from or writes to up to 64 embedded heads at a time

70 Comments on Hard Rectangular Drive Could be the Hard Disk Answer to SSDs

Fingers crossed.

Plus 500MB/sec is amazing from a single drive - raid 0 a couple for 1GB/sec read speeds *faints from thought of those speeds*

Of course SSDs will still have better latencies but we could now see these with faster speeds vs. the better latencies of SSDs - decisions, decisions...

Thanks for the info Alexp :toast:

EDIT:It still vibrates, the media platter moves, and more than before it's in direct contact with lubricant solid matter...that concerns me because there is no such thing as 0% friction and heat and wear and tear could still occur. But what do I know I'm not an engineer.

I hope it doesnt hum or even worse buzz :p

need reviews:D

Seriously I imagine it's bound to produce more noise than a SSD. The quantification of that "more" remains open to debate & tests.

lol, they have reinvented the wheel, and made it square! seems that with those 64 heads one on each sector, the "disk" still has to move quite a long way, about 1cm? or am i getting this wrong?

It will be louder than any fan you've ever heard and we'll nickname it "The Mosquito".

is it the data which moves to the heads?

There are read/write heads covering the top and bottom layers while the middle layer moves only at the nano-scale. The data "goes to" the heads but there are so many heads the data layer hardly moves at all.

The lubricant is a solid synth diamond coating that "protects the surfaces for years of worry free service". cant we just keep them separated by a nice vacuum that.. ahem... I dont know is in theory frictionless?

I'm not assuming I know better than ppl that actually know what can or cant be done of course.

seriously, i can normally keep up with tech and figure it out fast... this one just makes me :twitch:

The rectangle is split into 64 sectors, each with one head. These can all read or write at once. But the head is not fixed. There are 1000s of them on the surface made of semiconductor, but only one of these works at any one time within the sector. Which one is used is addressed by row/column. This allows the "coarse" control over the movement around the "disk".

In conjunction with this the whole "disk" moves by the piezo actuators. This allows the "fine" control over the movement of the deads to the desired location.

"A diamond solid lubricant coating protects the surfaces for years of worry free service"

It cant be a paste because nothing is more abrasive as loose diamond particles. That's what they coat on power cutting tool blades. Kind of not the effect one would want on a sensitive magnetic media.

Also even if on a molecular level the diamond coating is perfectly plane, heat still occurs because of fast moving tangent surfaces. Where there's heat there's entropy.