Purdue University Develops Next-Gen, 3D Intrachip Cooling Technology

Researchers based on Purdue University have designed an intrachip cooling technology, which will likely pave the way for future generations of high performance 3D microprocessors. The research was part of a DARPA-funded commission for Purdue University's Birck Nanotechnology Center; a fundamental requirement stipulated by DARPA was the ability for this cooling system to handle chips generating 1 kW of heat per cm², more than 10x the amount current high-performance computers generate.

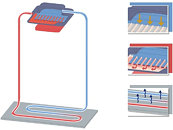

The new cooling system circulates an electrically insulated liquid coolant directly into electronic chips through an intricate series of tiny microchannels. This means that no longer will cooling systems be limited to the nowadays-employed conventional chip-cooling methods, which make use of finned metal plates called heat sinks. These are attached to computer chips to dissipate heat, but have a fundamental flaw: they do not remove heat efficiently enough for an emerging class of high-performance, 3D electronics, where too much heat hinders the performance of electronic chips or damages the tiny circuitry, especially in small "hot spots" that are located below the topmost layer of the chip.

The new cooling system circulates an electrically insulated liquid coolant directly into electronic chips through an intricate series of tiny microchannels. This means that no longer will cooling systems be limited to the nowadays-employed conventional chip-cooling methods, which make use of finned metal plates called heat sinks. These are attached to computer chips to dissipate heat, but have a fundamental flaw: they do not remove heat efficiently enough for an emerging class of high-performance, 3D electronics, where too much heat hinders the performance of electronic chips or damages the tiny circuitry, especially in small "hot spots" that are located below the topmost layer of the chip.