Annual DRAM Revenue for 2022 Expected to Reach US$91.5 Billion, with Prices Likely to Rally in 2H22, Says TrendForce

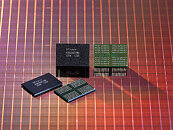

Despite the forecasted 18.6% YoY growth in total DRAM bit supply next year, the global DRAM market is still expected to shift from a shortage situation to an oversupply, according to TrendForce's latest investigations. This shift can primarily be attributed to the fact that, not only are most buyers now carrying a relatively high level of DRAM inventory, but DRAM bit demand is also expected to increase by only 17.1% YoY in 2022. On the price front, the oversupply situation will result in a drop in DRAM ASP in 2022 but not a major decline in annual DRAM revenue, thanks to the oligopolistic nature of the DRAM industry. Annual DRAM revenue for 2022 is expected to reach US$91.54 billion, which represents a slight YoY increase of 0.3%.

Based on an analysis of DRAM sufficiency ratio (which refers to the surplus of supply in comparison with demand) for each quarter in 2022, TrendForce forecasts a 15% YoY decrease in DRAM ASP for 2022, with prices undergoing the more noticeable declines during the first half of the year. Heading into 2H22, however, owing to the rise in DDR5 penetration rate, as well as the arrival of peak seasonal demand, the decline in DRAM ASP will likely narrow. TrendForce does not rule out the possibility that DRAM ASP may even hold flat or undergo an increase in 2H22.

Based on an analysis of DRAM sufficiency ratio (which refers to the surplus of supply in comparison with demand) for each quarter in 2022, TrendForce forecasts a 15% YoY decrease in DRAM ASP for 2022, with prices undergoing the more noticeable declines during the first half of the year. Heading into 2H22, however, owing to the rise in DDR5 penetration rate, as well as the arrival of peak seasonal demand, the decline in DRAM ASP will likely narrow. TrendForce does not rule out the possibility that DRAM ASP may even hold flat or undergo an increase in 2H22.