Thursday, September 21st 2017

Intel Delays 10nm "Cannon Lake" to Late-2018

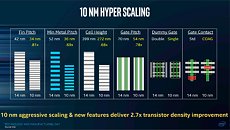

Intel is reportedly delaying the roll-out of its first processors built on its 10 nanometer silicon fabrication process, codenamed "Cannon Lake" for the third time since its inception. The first products based on the silicon will now come out only by late-2018. In the meantime, Intel could continue to ride on its new 8th generation Core "Coffee Lake" processors, including the augmentation of an 8-core mainstream desktop (MSDT) part in the second-half of 2018.

Notebook manufacturers are less than enthusiastic about "Cannon Lake," and plan to skip it altogether for its successor, codenamed "Ice Lake," which could come out in 2019. It won't be the first time OEMs have done this, as Intel's 5th generation Core "Broadwell" architecture was mostly skipped over in the notebook and MSDT segments.

Sources:

Electronics Weekly, DigiTimes

Notebook manufacturers are less than enthusiastic about "Cannon Lake," and plan to skip it altogether for its successor, codenamed "Ice Lake," which could come out in 2019. It won't be the first time OEMs have done this, as Intel's 5th generation Core "Broadwell" architecture was mostly skipped over in the notebook and MSDT segments.

15 Comments on Intel Delays 10nm "Cannon Lake" to Late-2018

(I know there has been success with 7nm neowafers but I don't see a future for it in msdt)

Even 1nm is on the roadmap after 2020, while going bellow, a different material than Silicon is going to be used... Relax, 10 more years from now on we will still see a 3% performance increase from Intel every year, no worries. :laugh::laugh::laugh:

The problem isn't silicon per se, the problem is physics and economic cost. All these silicon alternatives you have seen being flashed around for decades are being used already by the industry on their own niches, so it's not like there is an unaccounted or untested unobtanium of computer chips out there.

I wonder what's next in store.

Also influences how much latency you incur for a given core size as the larger the area the higher the internal latency, potential minor performance increase.

Whether these are passed down into a product stack is a completely different matter... remember that while there were 8 generations of quad core MSDT processors from intel, the server CPUs went from 4 to 22 in the first 5

newsroom.intel.com/newsroom/wp-content/uploads/sites/11/2017/09/mark-bohr-on-intels-technology-leadership.pdf